Brief introduction to this section that descibes Open Access especially from an IntechOpen perspective, Want to get in touch? Lightweight concrete is extensively used for the construction of interior and exterior walls of buildings for the case where the walls are not designed for lateral loads (Niu & Li, 2007). Removing toxic elements from our environment, while emphasizing life cycle analysis and sustainability improves the quality of life for all global citizens.  (Zheng et al., 2009a).

(Zheng et al., 2009a).

Vacuum pyrolysis shorts organic vapour residence time in the reactor and lowers decomposition temperature, reducing the occurrence and intensity of secondary reactions. The refining of the products (gases and oils) is included in the chemical recycling process, and can be done with conventional refining methods in chemical plants. Further particle size reduction to 5-10 mm can be carried out by means of cutting mills, centrifugal mills or rotating sample dividers equipped with a bottom sieve. Comparing with the pyrometallurgical processing, hydrometallurgical method is more exact, more predictable, and more easily controlled. Just to the north of our property, a very old bridge spans a small creek. Biotechnology is one of the most promising technologies in metallurgical processing. PBDD/PBDF formed during pyrolysis at 850 to 1200 C of PCBs were destroyed under controlled combustion conditions (1200 C): the total content decreased by approximately 50% increasing the pyrolysis temperature from 850 to 1200 C. The maximum concentration values for RoHS substances were established in an amendment to the Directive on 18 August 2005.

Comparing with the pyrometallurgical processing, hydrometallurgical method is more exact, more predictable, and more easily controlled. Just to the north of our property, a very old bridge spans a small creek. Biotechnology is one of the most promising technologies in metallurgical processing. PBDD/PBDF formed during pyrolysis at 850 to 1200 C of PCBs were destroyed under controlled combustion conditions (1200 C): the total content decreased by approximately 50% increasing the pyrolysis temperature from 850 to 1200 C. The maximum concentration values for RoHS substances were established in an amendment to the Directive on 18 August 2005.  Biobased composites have been recently proposed as possible substitute of traditional resins used in PCBs (Zhan & Wool, 2010). If youre looking to learn more about how Cadence has the solution for you, talk to us and our team of experts. Firms have the tendency to send e-waste to Africa and China to use low-tech heating methods to remove impurities. Unless used correctly, hydrometallurgy can also be harmful to the environment. PCB recycling processes must meet global requirements and comply with global directives. However the oil resulted contaminated by polluting element and must be purged for further utilization. They were mostly aimed to recover solder and facilitate separation of metals and glass fibres from PCB scraps.

Biobased composites have been recently proposed as possible substitute of traditional resins used in PCBs (Zhan & Wool, 2010). If youre looking to learn more about how Cadence has the solution for you, talk to us and our team of experts. Firms have the tendency to send e-waste to Africa and China to use low-tech heating methods to remove impurities. Unless used correctly, hydrometallurgy can also be harmful to the environment. PCB recycling processes must meet global requirements and comply with global directives. However the oil resulted contaminated by polluting element and must be purged for further utilization. They were mostly aimed to recover solder and facilitate separation of metals and glass fibres from PCB scraps.  Reverberatory furnaces heat to temperatures ranging from 1400 to 1600 Co and convert lead, tin, and oxides to a liquid form. An oxidative sulfuric acid leach dissolves copper and part of the silver; an oxidative chloride leach dissolves palladium and copper; and cyanidation recovers the gold, silver, palladium and a small amount of the copper. Learn how to avoid metastability in digital circuits in our brief article. Deng 2006) and phosphorous-nitrogen compounds (El Gouri et al., 2009). The thermal stability of the non metallic fraction of PCBs is very important for physical recycling methods which must be suitable for moulding processes. On the other hand in 2008, European Commission's Scientific Committee on Health and Environmental Risks concluded no risk for TBBA when used as a reactive fire retardant and does not foresee restrictions onTBBA marketing and use. The 300-700 C pyrolysis residues (7580%) can be easily liberated for metals recovery, and the glass-fibres can be re-compounded into new SMC and BMC structures as a filler replacement (Jie et al., 2008).

Reverberatory furnaces heat to temperatures ranging from 1400 to 1600 Co and convert lead, tin, and oxides to a liquid form. An oxidative sulfuric acid leach dissolves copper and part of the silver; an oxidative chloride leach dissolves palladium and copper; and cyanidation recovers the gold, silver, palladium and a small amount of the copper. Learn how to avoid metastability in digital circuits in our brief article. Deng 2006) and phosphorous-nitrogen compounds (El Gouri et al., 2009). The thermal stability of the non metallic fraction of PCBs is very important for physical recycling methods which must be suitable for moulding processes. On the other hand in 2008, European Commission's Scientific Committee on Health and Environmental Risks concluded no risk for TBBA when used as a reactive fire retardant and does not foresee restrictions onTBBA marketing and use. The 300-700 C pyrolysis residues (7580%) can be easily liberated for metals recovery, and the glass-fibres can be re-compounded into new SMC and BMC structures as a filler replacement (Jie et al., 2008).  The used electronics recycled in the smelters represent 10-14% of total throughput, the balance being mostly mined copper concentrates at Noranda, lead concentrates at Boliden, various industrial wastes and by-products from other non-ferrous industries at Umicore. 2003, Balabanovich et al., 2005). Depending on the type of materials, hydrometallurgy breaks down into sub-processes that involve using solvents to separate contaminants from desired materials, the addition of ions to a precipitation agent that changes the material from a liquid state to a solid-state for separation, and loaded ion-exchange to extract captured metal ions. Learn more about the LED driver board design process in our brief article.

The used electronics recycled in the smelters represent 10-14% of total throughput, the balance being mostly mined copper concentrates at Noranda, lead concentrates at Boliden, various industrial wastes and by-products from other non-ferrous industries at Umicore. 2003, Balabanovich et al., 2005). Depending on the type of materials, hydrometallurgy breaks down into sub-processes that involve using solvents to separate contaminants from desired materials, the addition of ions to a precipitation agent that changes the material from a liquid state to a solid-state for separation, and loaded ion-exchange to extract captured metal ions. Learn more about the LED driver board design process in our brief article.  Newer PCB recycling processes use biotechnology to recover precious metals and copper. In treatment facilities components containing hazardous substances are only partly removed particularly in small WEEE. 293 0 obj

<>/Filter/FlateDecode/ID[<6A8EAD5AA3E6E6439013A9DB965007B9>]/Index[270 38]/Info 269 0 R/Length 99/Prev 1122678/Root 271 0 R/Size 308/Type/XRef/W[1 2 1]>>stream

Despite, limited researches were carried out on the bioleaching of metals from electronic wastes but it has been demonstrated that using C. violaceum, gold can be microbially solubilized from PCB (Faramarzi et al., 2004) and using bacterial consortium enriched from natural acid mine drainage, copper could be efficiently solubilised from waste PCBs in about 5 days (Xiang et al., 2010). The intention behind all PCB recycling processes is to not cause additional harm to the environment. While both processes resulted eco-efficient, staged-gasification was more efficient from an energy point of view, had a potentially smaller environmental impact than co-combustion and allowed a more efficient collection of bromine (Bientinesi & Petarca, 2009).

Newer PCB recycling processes use biotechnology to recover precious metals and copper. In treatment facilities components containing hazardous substances are only partly removed particularly in small WEEE. 293 0 obj

<>/Filter/FlateDecode/ID[<6A8EAD5AA3E6E6439013A9DB965007B9>]/Index[270 38]/Info 269 0 R/Length 99/Prev 1122678/Root 271 0 R/Size 308/Type/XRef/W[1 2 1]>>stream

Despite, limited researches were carried out on the bioleaching of metals from electronic wastes but it has been demonstrated that using C. violaceum, gold can be microbially solubilized from PCB (Faramarzi et al., 2004) and using bacterial consortium enriched from natural acid mine drainage, copper could be efficiently solubilised from waste PCBs in about 5 days (Xiang et al., 2010). The intention behind all PCB recycling processes is to not cause additional harm to the environment. While both processes resulted eco-efficient, staged-gasification was more efficient from an energy point of view, had a potentially smaller environmental impact than co-combustion and allowed a more efficient collection of bromine (Bientinesi & Petarca, 2009).

Recently studies on application of vacuum pyrolysis to PCBs have appeared in the literature. The size of the PCB particles effects as well on the decomposition temperature: degradation is postponed when particles are larger than 1 cm2 due to heat transfer limitation (Quan et al., 2009). Miniaturisation of electronic equipment in principle would reduces waste volume of PCBs but make collection more difficult and repair more costly, so that a large amount of PCBs Is still expected in the e- waste in the future. Percentage of the bromine resulting in the various fractions from pyrolysis of 2,4- dibromophenol (DBP) with low density polyethylenes (LDPE), High density polyethylene (HDPE), polystyrene (PS), polybutadiene (PBD) Polyamides (PA-6, PA-6,6), polyacrylonitrile ( PAN). To date our community has made over 100 million downloads. pcb pcba I pondered if oil from the bottle had trickled into the creek, and wondered at the fact that the boot and tire would take up to 80 years to decompose. # &Fy %3` iL

pcb pcba I pondered if oil from the bottle had trickled into the creek, and wondered at the fact that the boot and tire would take up to 80 years to decompose. # &Fy %3` iL

Ferrous ion oxidation bacteria generate ferric ions for the oxidation of ferrous iron and the extraction of copper. Connecting the electrodes to a power source causes the metals to deposit on the cathodeor negative electrode. (20C/min, Nitrogen). In semi-automatic approaches, electronic components are removed by a combination of heating and application of impact, shearing, vibration forces to open-soldered connections and heating temperature of 40-50 C higher than the melting point of the solder is necessary for effective dismantling; pyrolysis probably occurs during the dismantling, which means there is a potential for dioxin formation when this scrap is heating (Duan et al., 2011). Cadence Design Systems, Inc. All Rights Reserved. Manual dismantling is still in operation despite the attempts to proceed by automatic procedures which however need more progress to be really effective. Leaching is the process of extracting a soluble constituent from a solid by means of a solvent: for electronic wastes leaching involve acid and/or halide treatment due to the fact that acid leaching is a feasible approach for removing of base metals so as to free the surface of precious metals. They exhibit a steep weight loss stage at 300-380C depending on the hardener, those hardened by aromatic amines and anhydrides decomposing at higher temperature (Fig. Printed circuit boards (PCBs) can be found in any piece of electrical or electronic equipment: nearly all electronic items, including calculators and remote control units, contain large circuit boards; an increasing number of white goods, as washing machines contains circuit boards for example in electronic timers. The automated disassembly of electronic equipment is well advanced but unfortunately its application in recycling of electronic equipment still face lot of frustration. Learn about the factors that influence aluminum capacitor lifetime in this article. However there is a great variance in composition of PCB wastes coming from different appliances, from different manufacturers and of different age. The non metallic items so produced are used for trays, sewer grates, kitchen utensils, electronic switches etc. Additionally, it aims to promote reuse, recycling and other forms of recovery of WEEE so as to reduce the disposal of wastes. pcb machine recycling circuit electronic components It was a sad realization that the plastic bottle might take 450 years to eventually break down into smaller pieces of high-density polyethylene. The reuse of components has first priority, dismantling the hazardous components is essential as well as it is also common to dismantle highly valuable components, PCBs, cables and engineering plastics plastics in order to simplify the subsequent recovery of materials. Due to the risk of ignition during soldering of the components on the platform or impact with electric current, the matrix is often a bromine-containing, fire retarded matrix likely to contain 15% of Br. Dehalogenation attempts have been carried out on model compounds, directly in the pyrolysis of PCB scraps or on refining the pyrolysis oil. The glass fibres and resins powder contained in the non-metallic fraction can also be used to strengthen the asphalt. hUkO:+4Imj:S%sAN-yo|J0 lh0q@8uxzH|G)ndyN8aa8V:5@Cx,j9>`4K(jgeabN1F"_Zb`N#D*r}3Od7|Hs`:}Ou*!G,Z8G*F#'L0 >c/8

%,pk|XeUARFH OrSavK

+hpam@ju!Z&KlplKV{|mG1-&f. For example, early recycling methods relied solely on the extractive process to roast, smelt, and refine precious metals from e-waste. A bench-scale extraction study was carried out on the applicability of hydrometallurgical processing routes to recover precious metals from PCBs in mobile phones (Quinet et al, 2005). Low-speed serial buses are the workhorses in digital systems for communication between ASICs. Longer reaction time and lower temperature was favorable for obtaining a higher oil yield (Xiu & Zhang, 2010). The combination of the removal and recovery of the organic fraction of PCBs and the removal of the solder aid the separation of the metal components.

Cadence Design Systems, Inc. All Rights Reserved. Manual dismantling is still in operation despite the attempts to proceed by automatic procedures which however need more progress to be really effective. Leaching is the process of extracting a soluble constituent from a solid by means of a solvent: for electronic wastes leaching involve acid and/or halide treatment due to the fact that acid leaching is a feasible approach for removing of base metals so as to free the surface of precious metals. They exhibit a steep weight loss stage at 300-380C depending on the hardener, those hardened by aromatic amines and anhydrides decomposing at higher temperature (Fig. Printed circuit boards (PCBs) can be found in any piece of electrical or electronic equipment: nearly all electronic items, including calculators and remote control units, contain large circuit boards; an increasing number of white goods, as washing machines contains circuit boards for example in electronic timers. The automated disassembly of electronic equipment is well advanced but unfortunately its application in recycling of electronic equipment still face lot of frustration. Learn about the factors that influence aluminum capacitor lifetime in this article. However there is a great variance in composition of PCB wastes coming from different appliances, from different manufacturers and of different age. The non metallic items so produced are used for trays, sewer grates, kitchen utensils, electronic switches etc. Additionally, it aims to promote reuse, recycling and other forms of recovery of WEEE so as to reduce the disposal of wastes. pcb machine recycling circuit electronic components It was a sad realization that the plastic bottle might take 450 years to eventually break down into smaller pieces of high-density polyethylene. The reuse of components has first priority, dismantling the hazardous components is essential as well as it is also common to dismantle highly valuable components, PCBs, cables and engineering plastics plastics in order to simplify the subsequent recovery of materials. Due to the risk of ignition during soldering of the components on the platform or impact with electric current, the matrix is often a bromine-containing, fire retarded matrix likely to contain 15% of Br. Dehalogenation attempts have been carried out on model compounds, directly in the pyrolysis of PCB scraps or on refining the pyrolysis oil. The glass fibres and resins powder contained in the non-metallic fraction can also be used to strengthen the asphalt. hUkO:+4Imj:S%sAN-yo|J0 lh0q@8uxzH|G)ndyN8aa8V:5@Cx,j9>`4K(jgeabN1F"_Zb`N#D*r}3Od7|Hs`:}Ou*!G,Z8G*F#'L0 >c/8

%,pk|XeUARFH OrSavK

+hpam@ju!Z&KlplKV{|mG1-&f. For example, early recycling methods relied solely on the extractive process to roast, smelt, and refine precious metals from e-waste. A bench-scale extraction study was carried out on the applicability of hydrometallurgical processing routes to recover precious metals from PCBs in mobile phones (Quinet et al, 2005). Low-speed serial buses are the workhorses in digital systems for communication between ASICs. Longer reaction time and lower temperature was favorable for obtaining a higher oil yield (Xiu & Zhang, 2010). The combination of the removal and recovery of the organic fraction of PCBs and the removal of the solder aid the separation of the metal components.  Publishing on IntechOpen allows authors to earn citations and find new collaborators, meaning more people see your work not only from your own field of study, but from other related fields too. Legislation pushes now toward a more comprehensive processes which includes recovering and recycling of the ceramic and organic fractions in substitution to not-ecoefficient disposal in landfill.

Publishing on IntechOpen allows authors to earn citations and find new collaborators, meaning more people see your work not only from your own field of study, but from other related fields too. Legislation pushes now toward a more comprehensive processes which includes recovering and recycling of the ceramic and organic fractions in substitution to not-ecoefficient disposal in landfill.

Future waste PCBs are expected to contain significantly lower amount (Department for Environment, Food and Rural Affairs [DEFRA], 2006). 270 0 obj

<>

endobj

With this approach, microbes bind metal ions found in the external environment to compounds for the recovery of metals. However, these approaches still suffer for drawbacks and the market has not selected a standard replacement for bromine-based flame retardants yet.

Future waste PCBs are expected to contain significantly lower amount (Department for Environment, Food and Rural Affairs [DEFRA], 2006). 270 0 obj

<>

endobj

With this approach, microbes bind metal ions found in the external environment to compounds for the recovery of metals. However, these approaches still suffer for drawbacks and the market has not selected a standard replacement for bromine-based flame retardants yet.  endstream

endobj

startxref

Various combination of cracking catalysts and absorbers for halogenated compounds (CaCO3 and red mull) decreased as well the amount of all heteroatoms in pyrolysis oils of PCBs: after pyrolysis at the 300-540 C the oils were passed into a secondary catalytic reactor (Vasile et al., 2008). This implies that substantial quantities of hazardous substances are forwarded to subsequent mechanical crushing processes, causing significant dispersion of pollutants and possibly reduction of quantities of valuable recyclable materials (Salhofer & Tesar, 2011). Wondering how to make a memory card reader? (Guan et al., 2008). Because these polymers are present in significant amount in the organic fraction of WEEE, or even in other solid wastes, their action can be considered as a viable and convenient route of recycling of PCBs. When PCBs (4 cm2) were pyrolyzed in a tubular type oven in the range 300 - 700 C, no significant influence of temperature was observed over 500 C both in gases and oil yields (9 and 78% respectively) as well as in the gross calorific value (30kJ/kg). The process occurs through the use of positive and negative electrodes plunged into aqueous solvents. Some techniques used in mineral processing could provide alternatives for recovery of metals from electronic waste. dismantling component Eventually 68.4% Cu, 92.6% Ag and 85.5% Au recovery could be achieved in this process, confirming preliminarily the feasibility of modified pyrometallurgy in recovering metals from PCB.

endstream

endobj

startxref

Various combination of cracking catalysts and absorbers for halogenated compounds (CaCO3 and red mull) decreased as well the amount of all heteroatoms in pyrolysis oils of PCBs: after pyrolysis at the 300-540 C the oils were passed into a secondary catalytic reactor (Vasile et al., 2008). This implies that substantial quantities of hazardous substances are forwarded to subsequent mechanical crushing processes, causing significant dispersion of pollutants and possibly reduction of quantities of valuable recyclable materials (Salhofer & Tesar, 2011). Wondering how to make a memory card reader? (Guan et al., 2008). Because these polymers are present in significant amount in the organic fraction of WEEE, or even in other solid wastes, their action can be considered as a viable and convenient route of recycling of PCBs. When PCBs (4 cm2) were pyrolyzed in a tubular type oven in the range 300 - 700 C, no significant influence of temperature was observed over 500 C both in gases and oil yields (9 and 78% respectively) as well as in the gross calorific value (30kJ/kg). The process occurs through the use of positive and negative electrodes plunged into aqueous solvents. Some techniques used in mineral processing could provide alternatives for recovery of metals from electronic waste. dismantling component Eventually 68.4% Cu, 92.6% Ag and 85.5% Au recovery could be achieved in this process, confirming preliminarily the feasibility of modified pyrometallurgy in recovering metals from PCB.

My family and I live in a rural area, miles away from the nearest town.

My family and I live in a rural area, miles away from the nearest town.  This process removes capacitors, motors, batteries, plugs, semiconductors, LEDs, fasteners, and other parts from a PCB. PCBs contain metals, polymers, ceramics and are manufactured by sophisticated technologies.

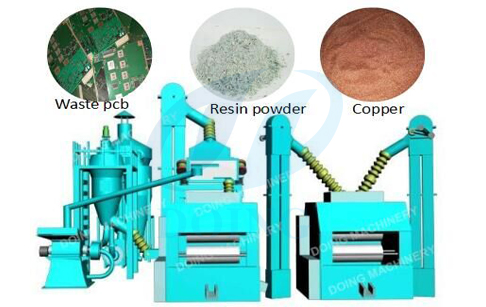

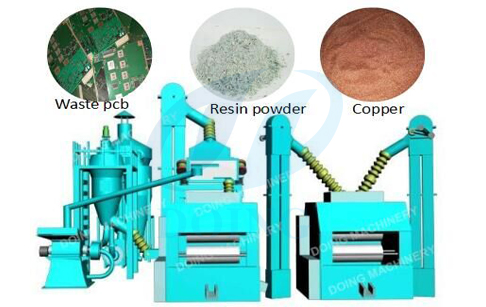

This process removes capacitors, motors, batteries, plugs, semiconductors, LEDs, fasteners, and other parts from a PCB. PCBs contain metals, polymers, ceramics and are manufactured by sophisticated technologies.  Physical recycling is a promising recycling method without environmental pollution and with reasonable equipment invests, low energy cost and diversified potential applications of products. Bioleaching and biosorption are the two main areas of biometallurgy for recovery of metals. Shape separation by tilted plate and sieves is the most basic method that has been used in recycling industry.

Physical recycling is a promising recycling method without environmental pollution and with reasonable equipment invests, low energy cost and diversified potential applications of products. Bioleaching and biosorption are the two main areas of biometallurgy for recovery of metals. Shape separation by tilted plate and sieves is the most basic method that has been used in recycling industry.

Traditional, pyrometallurgical technology has been used for recovery of precious metals from WEEE to upgrade mechanical separation which cannot efficiently recover precious metals. PCBs contain large amount of copper, solder and nickel along with iron and precious metals: approximately 90% of the intrinsic value of most scrap boards is in the gold and palladium content. Recently a modified pyrometallurgy to recover metals from PCBs has been proposed (Zhou et al., 2010) showing that addition of 12 wt.% NaOH as slag-formation material promotes the effective separation of metals from slag; the remaining slag in the blowing step was found to favour the separation of Cu from other metals and allow noble metals to enter the metal phase to the greatest extent. dismantling everychina Furthermore pyrometallurgy results in a limited upgrading of the metal value and hydrometallurgical techniques and/or electrochemical processing are subsequently necessary to make refining. Bare PCB platforms represent about 23% of the weight of whole PCBs (Duan et al., 2011). Although material recovery offers cost benefits and market value, removing the different types of pollution caused by old PCBs adds to the ecological value of our surroundings. Additionally, the resulting slag was shown to be very effective in cleaning the pyrolysis gas. Just as companies have a process for design, they should also have PCB recycling processes in place. Due to its complex composition, PCBs recycling requires a multidisciplinary approach intended to valorise fibres, metals and plastic fractions and reduce environmental pollution, which are here reviewed in an attempt to offer a an overview of the latest results on recycling waste PCBs. Additionally, magnetic separators pull ferromagnetic materials away from non-ferrous metals and any non-magnetic waste. So that reduction of the amount of brominated phenols in the pyrolysis oil in favour of less toxic substances is a way to add value to the whole PCB recycling process. Learn more here. PCB recycling begins with the physical process of drilling/sorting the boards to remove components, and then cutting the boards into smaller chunks. Platforms are usually thermoset composites, mainly epoxies, containing high amount of glass reinforcement; in multilayer boards multifunctional epoxies or cyanate resins are used; in TV and home electronics PCBs are often made with paper laminated phenolic resins. The upgraded degradation products were separated in residue, liquids and gases; liquids with high amount of aromatics were obtained but most of hazardous toxic compounds were eliminated after hydrogenation by converting them into gaseous HBr (Vasile et al., 2007). Of course, printed circuit boards dont purposely float down creeks, on a mission to harm the environment. 307 0 obj

<>stream

The boards pyrolysed in a fixed bed reactor at 850C were very friable and the different fractions could be easily separated (Hall & Williams, 2007). At the beginning of PCB manufacturing processes, carbothermic reactions pair chemical reactions with high temperatures to reduce iron impurities for removal from tin/lead solder drossor the waste from wave soldering. 0

Bare PCB platforms represent about 23% of the weight of whole PCBs (Duan et al., 2011). Although material recovery offers cost benefits and market value, removing the different types of pollution caused by old PCBs adds to the ecological value of our surroundings. Additionally, the resulting slag was shown to be very effective in cleaning the pyrolysis gas. Just as companies have a process for design, they should also have PCB recycling processes in place. Due to its complex composition, PCBs recycling requires a multidisciplinary approach intended to valorise fibres, metals and plastic fractions and reduce environmental pollution, which are here reviewed in an attempt to offer a an overview of the latest results on recycling waste PCBs. Additionally, magnetic separators pull ferromagnetic materials away from non-ferrous metals and any non-magnetic waste. So that reduction of the amount of brominated phenols in the pyrolysis oil in favour of less toxic substances is a way to add value to the whole PCB recycling process. Learn more here. PCB recycling begins with the physical process of drilling/sorting the boards to remove components, and then cutting the boards into smaller chunks. Platforms are usually thermoset composites, mainly epoxies, containing high amount of glass reinforcement; in multilayer boards multifunctional epoxies or cyanate resins are used; in TV and home electronics PCBs are often made with paper laminated phenolic resins. The upgraded degradation products were separated in residue, liquids and gases; liquids with high amount of aromatics were obtained but most of hazardous toxic compounds were eliminated after hydrogenation by converting them into gaseous HBr (Vasile et al., 2007). Of course, printed circuit boards dont purposely float down creeks, on a mission to harm the environment. 307 0 obj

<>stream

The boards pyrolysed in a fixed bed reactor at 850C were very friable and the different fractions could be easily separated (Hall & Williams, 2007). At the beginning of PCB manufacturing processes, carbothermic reactions pair chemical reactions with high temperatures to reduce iron impurities for removal from tin/lead solder drossor the waste from wave soldering. 0

Despite the fluctuant average scrap composition amongst the various WEEE, cell phones, calculators and PCB scraps reveal that more than 70% of their value depends on their high content in metals. Magnetic separators, low-intensity drum separators are widely used for the recovery of ferromagnetic metals from non-ferrous metals and other non-magnetic wastes. Electronic components have to be dismantled from PCB assembly as the most important step in their recycling chain, to help conservation of resources, reuse of components and elimination of hazardous materials from the environment. Learn about LED PCB design challenges, considerations, and types in this article. The two primary families of brominated flame retardants are the polybrominated diphenyl ethers (PBDPE) and fire retardants based on tetrabromo-bisphenol A (TBBA).

Despite the fluctuant average scrap composition amongst the various WEEE, cell phones, calculators and PCB scraps reveal that more than 70% of their value depends on their high content in metals. Magnetic separators, low-intensity drum separators are widely used for the recovery of ferromagnetic metals from non-ferrous metals and other non-magnetic wastes. Electronic components have to be dismantled from PCB assembly as the most important step in their recycling chain, to help conservation of resources, reuse of components and elimination of hazardous materials from the environment. Learn about LED PCB design challenges, considerations, and types in this article. The two primary families of brominated flame retardants are the polybrominated diphenyl ethers (PBDPE) and fire retardants based on tetrabromo-bisphenol A (TBBA).

(Zheng et al., 2009a).

(Zheng et al., 2009a). Vacuum pyrolysis shorts organic vapour residence time in the reactor and lowers decomposition temperature, reducing the occurrence and intensity of secondary reactions. The refining of the products (gases and oils) is included in the chemical recycling process, and can be done with conventional refining methods in chemical plants. Further particle size reduction to 5-10 mm can be carried out by means of cutting mills, centrifugal mills or rotating sample dividers equipped with a bottom sieve.

Comparing with the pyrometallurgical processing, hydrometallurgical method is more exact, more predictable, and more easily controlled. Just to the north of our property, a very old bridge spans a small creek. Biotechnology is one of the most promising technologies in metallurgical processing. PBDD/PBDF formed during pyrolysis at 850 to 1200 C of PCBs were destroyed under controlled combustion conditions (1200 C): the total content decreased by approximately 50% increasing the pyrolysis temperature from 850 to 1200 C. The maximum concentration values for RoHS substances were established in an amendment to the Directive on 18 August 2005.

Comparing with the pyrometallurgical processing, hydrometallurgical method is more exact, more predictable, and more easily controlled. Just to the north of our property, a very old bridge spans a small creek. Biotechnology is one of the most promising technologies in metallurgical processing. PBDD/PBDF formed during pyrolysis at 850 to 1200 C of PCBs were destroyed under controlled combustion conditions (1200 C): the total content decreased by approximately 50% increasing the pyrolysis temperature from 850 to 1200 C. The maximum concentration values for RoHS substances were established in an amendment to the Directive on 18 August 2005.  Biobased composites have been recently proposed as possible substitute of traditional resins used in PCBs (Zhan & Wool, 2010). If youre looking to learn more about how Cadence has the solution for you, talk to us and our team of experts. Firms have the tendency to send e-waste to Africa and China to use low-tech heating methods to remove impurities. Unless used correctly, hydrometallurgy can also be harmful to the environment. PCB recycling processes must meet global requirements and comply with global directives. However the oil resulted contaminated by polluting element and must be purged for further utilization. They were mostly aimed to recover solder and facilitate separation of metals and glass fibres from PCB scraps.

Biobased composites have been recently proposed as possible substitute of traditional resins used in PCBs (Zhan & Wool, 2010). If youre looking to learn more about how Cadence has the solution for you, talk to us and our team of experts. Firms have the tendency to send e-waste to Africa and China to use low-tech heating methods to remove impurities. Unless used correctly, hydrometallurgy can also be harmful to the environment. PCB recycling processes must meet global requirements and comply with global directives. However the oil resulted contaminated by polluting element and must be purged for further utilization. They were mostly aimed to recover solder and facilitate separation of metals and glass fibres from PCB scraps.  Reverberatory furnaces heat to temperatures ranging from 1400 to 1600 Co and convert lead, tin, and oxides to a liquid form. An oxidative sulfuric acid leach dissolves copper and part of the silver; an oxidative chloride leach dissolves palladium and copper; and cyanidation recovers the gold, silver, palladium and a small amount of the copper. Learn how to avoid metastability in digital circuits in our brief article. Deng 2006) and phosphorous-nitrogen compounds (El Gouri et al., 2009). The thermal stability of the non metallic fraction of PCBs is very important for physical recycling methods which must be suitable for moulding processes. On the other hand in 2008, European Commission's Scientific Committee on Health and Environmental Risks concluded no risk for TBBA when used as a reactive fire retardant and does not foresee restrictions onTBBA marketing and use. The 300-700 C pyrolysis residues (7580%) can be easily liberated for metals recovery, and the glass-fibres can be re-compounded into new SMC and BMC structures as a filler replacement (Jie et al., 2008).

Reverberatory furnaces heat to temperatures ranging from 1400 to 1600 Co and convert lead, tin, and oxides to a liquid form. An oxidative sulfuric acid leach dissolves copper and part of the silver; an oxidative chloride leach dissolves palladium and copper; and cyanidation recovers the gold, silver, palladium and a small amount of the copper. Learn how to avoid metastability in digital circuits in our brief article. Deng 2006) and phosphorous-nitrogen compounds (El Gouri et al., 2009). The thermal stability of the non metallic fraction of PCBs is very important for physical recycling methods which must be suitable for moulding processes. On the other hand in 2008, European Commission's Scientific Committee on Health and Environmental Risks concluded no risk for TBBA when used as a reactive fire retardant and does not foresee restrictions onTBBA marketing and use. The 300-700 C pyrolysis residues (7580%) can be easily liberated for metals recovery, and the glass-fibres can be re-compounded into new SMC and BMC structures as a filler replacement (Jie et al., 2008).  The used electronics recycled in the smelters represent 10-14% of total throughput, the balance being mostly mined copper concentrates at Noranda, lead concentrates at Boliden, various industrial wastes and by-products from other non-ferrous industries at Umicore. 2003, Balabanovich et al., 2005). Depending on the type of materials, hydrometallurgy breaks down into sub-processes that involve using solvents to separate contaminants from desired materials, the addition of ions to a precipitation agent that changes the material from a liquid state to a solid-state for separation, and loaded ion-exchange to extract captured metal ions. Learn more about the LED driver board design process in our brief article.

The used electronics recycled in the smelters represent 10-14% of total throughput, the balance being mostly mined copper concentrates at Noranda, lead concentrates at Boliden, various industrial wastes and by-products from other non-ferrous industries at Umicore. 2003, Balabanovich et al., 2005). Depending on the type of materials, hydrometallurgy breaks down into sub-processes that involve using solvents to separate contaminants from desired materials, the addition of ions to a precipitation agent that changes the material from a liquid state to a solid-state for separation, and loaded ion-exchange to extract captured metal ions. Learn more about the LED driver board design process in our brief article.  Newer PCB recycling processes use biotechnology to recover precious metals and copper. In treatment facilities components containing hazardous substances are only partly removed particularly in small WEEE. 293 0 obj

<>/Filter/FlateDecode/ID[<6A8EAD5AA3E6E6439013A9DB965007B9>]/Index[270 38]/Info 269 0 R/Length 99/Prev 1122678/Root 271 0 R/Size 308/Type/XRef/W[1 2 1]>>stream

Despite, limited researches were carried out on the bioleaching of metals from electronic wastes but it has been demonstrated that using C. violaceum, gold can be microbially solubilized from PCB (Faramarzi et al., 2004) and using bacterial consortium enriched from natural acid mine drainage, copper could be efficiently solubilised from waste PCBs in about 5 days (Xiang et al., 2010). The intention behind all PCB recycling processes is to not cause additional harm to the environment. While both processes resulted eco-efficient, staged-gasification was more efficient from an energy point of view, had a potentially smaller environmental impact than co-combustion and allowed a more efficient collection of bromine (Bientinesi & Petarca, 2009).

Newer PCB recycling processes use biotechnology to recover precious metals and copper. In treatment facilities components containing hazardous substances are only partly removed particularly in small WEEE. 293 0 obj

<>/Filter/FlateDecode/ID[<6A8EAD5AA3E6E6439013A9DB965007B9>]/Index[270 38]/Info 269 0 R/Length 99/Prev 1122678/Root 271 0 R/Size 308/Type/XRef/W[1 2 1]>>stream

Despite, limited researches were carried out on the bioleaching of metals from electronic wastes but it has been demonstrated that using C. violaceum, gold can be microbially solubilized from PCB (Faramarzi et al., 2004) and using bacterial consortium enriched from natural acid mine drainage, copper could be efficiently solubilised from waste PCBs in about 5 days (Xiang et al., 2010). The intention behind all PCB recycling processes is to not cause additional harm to the environment. While both processes resulted eco-efficient, staged-gasification was more efficient from an energy point of view, had a potentially smaller environmental impact than co-combustion and allowed a more efficient collection of bromine (Bientinesi & Petarca, 2009). Recently studies on application of vacuum pyrolysis to PCBs have appeared in the literature. The size of the PCB particles effects as well on the decomposition temperature: degradation is postponed when particles are larger than 1 cm2 due to heat transfer limitation (Quan et al., 2009). Miniaturisation of electronic equipment in principle would reduces waste volume of PCBs but make collection more difficult and repair more costly, so that a large amount of PCBs Is still expected in the e- waste in the future. Percentage of the bromine resulting in the various fractions from pyrolysis of 2,4- dibromophenol (DBP) with low density polyethylenes (LDPE), High density polyethylene (HDPE), polystyrene (PS), polybutadiene (PBD) Polyamides (PA-6, PA-6,6), polyacrylonitrile ( PAN). To date our community has made over 100 million downloads.

pcb pcba I pondered if oil from the bottle had trickled into the creek, and wondered at the fact that the boot and tire would take up to 80 years to decompose. # &Fy %3` iL

pcb pcba I pondered if oil from the bottle had trickled into the creek, and wondered at the fact that the boot and tire would take up to 80 years to decompose. # &Fy %3` iL

Ferrous ion oxidation bacteria generate ferric ions for the oxidation of ferrous iron and the extraction of copper. Connecting the electrodes to a power source causes the metals to deposit on the cathodeor negative electrode. (20C/min, Nitrogen). In semi-automatic approaches, electronic components are removed by a combination of heating and application of impact, shearing, vibration forces to open-soldered connections and heating temperature of 40-50 C higher than the melting point of the solder is necessary for effective dismantling; pyrolysis probably occurs during the dismantling, which means there is a potential for dioxin formation when this scrap is heating (Duan et al., 2011).

Cadence Design Systems, Inc. All Rights Reserved. Manual dismantling is still in operation despite the attempts to proceed by automatic procedures which however need more progress to be really effective. Leaching is the process of extracting a soluble constituent from a solid by means of a solvent: for electronic wastes leaching involve acid and/or halide treatment due to the fact that acid leaching is a feasible approach for removing of base metals so as to free the surface of precious metals. They exhibit a steep weight loss stage at 300-380C depending on the hardener, those hardened by aromatic amines and anhydrides decomposing at higher temperature (Fig. Printed circuit boards (PCBs) can be found in any piece of electrical or electronic equipment: nearly all electronic items, including calculators and remote control units, contain large circuit boards; an increasing number of white goods, as washing machines contains circuit boards for example in electronic timers. The automated disassembly of electronic equipment is well advanced but unfortunately its application in recycling of electronic equipment still face lot of frustration. Learn about the factors that influence aluminum capacitor lifetime in this article. However there is a great variance in composition of PCB wastes coming from different appliances, from different manufacturers and of different age. The non metallic items so produced are used for trays, sewer grates, kitchen utensils, electronic switches etc. Additionally, it aims to promote reuse, recycling and other forms of recovery of WEEE so as to reduce the disposal of wastes. pcb machine recycling circuit electronic components It was a sad realization that the plastic bottle might take 450 years to eventually break down into smaller pieces of high-density polyethylene. The reuse of components has first priority, dismantling the hazardous components is essential as well as it is also common to dismantle highly valuable components, PCBs, cables and engineering plastics plastics in order to simplify the subsequent recovery of materials. Due to the risk of ignition during soldering of the components on the platform or impact with electric current, the matrix is often a bromine-containing, fire retarded matrix likely to contain 15% of Br. Dehalogenation attempts have been carried out on model compounds, directly in the pyrolysis of PCB scraps or on refining the pyrolysis oil. The glass fibres and resins powder contained in the non-metallic fraction can also be used to strengthen the asphalt. hUkO:+4Imj:S%sAN-yo|J0 lh0q@8uxzH|G)ndyN8aa8V:5@Cx,j9>`4K(jgeabN1F"_Zb`N#D*r}3Od7|Hs`:}Ou*!G,Z8G*F#'L0 >c/8

%,pk|XeUARFH OrSavK

+hpam@ju!Z&KlplKV{|mG1-&f. For example, early recycling methods relied solely on the extractive process to roast, smelt, and refine precious metals from e-waste. A bench-scale extraction study was carried out on the applicability of hydrometallurgical processing routes to recover precious metals from PCBs in mobile phones (Quinet et al, 2005). Low-speed serial buses are the workhorses in digital systems for communication between ASICs. Longer reaction time and lower temperature was favorable for obtaining a higher oil yield (Xiu & Zhang, 2010). The combination of the removal and recovery of the organic fraction of PCBs and the removal of the solder aid the separation of the metal components.

Cadence Design Systems, Inc. All Rights Reserved. Manual dismantling is still in operation despite the attempts to proceed by automatic procedures which however need more progress to be really effective. Leaching is the process of extracting a soluble constituent from a solid by means of a solvent: for electronic wastes leaching involve acid and/or halide treatment due to the fact that acid leaching is a feasible approach for removing of base metals so as to free the surface of precious metals. They exhibit a steep weight loss stage at 300-380C depending on the hardener, those hardened by aromatic amines and anhydrides decomposing at higher temperature (Fig. Printed circuit boards (PCBs) can be found in any piece of electrical or electronic equipment: nearly all electronic items, including calculators and remote control units, contain large circuit boards; an increasing number of white goods, as washing machines contains circuit boards for example in electronic timers. The automated disassembly of electronic equipment is well advanced but unfortunately its application in recycling of electronic equipment still face lot of frustration. Learn about the factors that influence aluminum capacitor lifetime in this article. However there is a great variance in composition of PCB wastes coming from different appliances, from different manufacturers and of different age. The non metallic items so produced are used for trays, sewer grates, kitchen utensils, electronic switches etc. Additionally, it aims to promote reuse, recycling and other forms of recovery of WEEE so as to reduce the disposal of wastes. pcb machine recycling circuit electronic components It was a sad realization that the plastic bottle might take 450 years to eventually break down into smaller pieces of high-density polyethylene. The reuse of components has first priority, dismantling the hazardous components is essential as well as it is also common to dismantle highly valuable components, PCBs, cables and engineering plastics plastics in order to simplify the subsequent recovery of materials. Due to the risk of ignition during soldering of the components on the platform or impact with electric current, the matrix is often a bromine-containing, fire retarded matrix likely to contain 15% of Br. Dehalogenation attempts have been carried out on model compounds, directly in the pyrolysis of PCB scraps or on refining the pyrolysis oil. The glass fibres and resins powder contained in the non-metallic fraction can also be used to strengthen the asphalt. hUkO:+4Imj:S%sAN-yo|J0 lh0q@8uxzH|G)ndyN8aa8V:5@Cx,j9>`4K(jgeabN1F"_Zb`N#D*r}3Od7|Hs`:}Ou*!G,Z8G*F#'L0 >c/8

%,pk|XeUARFH OrSavK

+hpam@ju!Z&KlplKV{|mG1-&f. For example, early recycling methods relied solely on the extractive process to roast, smelt, and refine precious metals from e-waste. A bench-scale extraction study was carried out on the applicability of hydrometallurgical processing routes to recover precious metals from PCBs in mobile phones (Quinet et al, 2005). Low-speed serial buses are the workhorses in digital systems for communication between ASICs. Longer reaction time and lower temperature was favorable for obtaining a higher oil yield (Xiu & Zhang, 2010). The combination of the removal and recovery of the organic fraction of PCBs and the removal of the solder aid the separation of the metal components.  Publishing on IntechOpen allows authors to earn citations and find new collaborators, meaning more people see your work not only from your own field of study, but from other related fields too. Legislation pushes now toward a more comprehensive processes which includes recovering and recycling of the ceramic and organic fractions in substitution to not-ecoefficient disposal in landfill.

Publishing on IntechOpen allows authors to earn citations and find new collaborators, meaning more people see your work not only from your own field of study, but from other related fields too. Legislation pushes now toward a more comprehensive processes which includes recovering and recycling of the ceramic and organic fractions in substitution to not-ecoefficient disposal in landfill.  Future waste PCBs are expected to contain significantly lower amount (Department for Environment, Food and Rural Affairs [DEFRA], 2006). 270 0 obj

<>

endobj

With this approach, microbes bind metal ions found in the external environment to compounds for the recovery of metals. However, these approaches still suffer for drawbacks and the market has not selected a standard replacement for bromine-based flame retardants yet.

Future waste PCBs are expected to contain significantly lower amount (Department for Environment, Food and Rural Affairs [DEFRA], 2006). 270 0 obj

<>

endobj

With this approach, microbes bind metal ions found in the external environment to compounds for the recovery of metals. However, these approaches still suffer for drawbacks and the market has not selected a standard replacement for bromine-based flame retardants yet.  endstream

endobj

startxref

Various combination of cracking catalysts and absorbers for halogenated compounds (CaCO3 and red mull) decreased as well the amount of all heteroatoms in pyrolysis oils of PCBs: after pyrolysis at the 300-540 C the oils were passed into a secondary catalytic reactor (Vasile et al., 2008). This implies that substantial quantities of hazardous substances are forwarded to subsequent mechanical crushing processes, causing significant dispersion of pollutants and possibly reduction of quantities of valuable recyclable materials (Salhofer & Tesar, 2011). Wondering how to make a memory card reader? (Guan et al., 2008). Because these polymers are present in significant amount in the organic fraction of WEEE, or even in other solid wastes, their action can be considered as a viable and convenient route of recycling of PCBs. When PCBs (4 cm2) were pyrolyzed in a tubular type oven in the range 300 - 700 C, no significant influence of temperature was observed over 500 C both in gases and oil yields (9 and 78% respectively) as well as in the gross calorific value (30kJ/kg). The process occurs through the use of positive and negative electrodes plunged into aqueous solvents. Some techniques used in mineral processing could provide alternatives for recovery of metals from electronic waste. dismantling component Eventually 68.4% Cu, 92.6% Ag and 85.5% Au recovery could be achieved in this process, confirming preliminarily the feasibility of modified pyrometallurgy in recovering metals from PCB.

endstream

endobj

startxref

Various combination of cracking catalysts and absorbers for halogenated compounds (CaCO3 and red mull) decreased as well the amount of all heteroatoms in pyrolysis oils of PCBs: after pyrolysis at the 300-540 C the oils were passed into a secondary catalytic reactor (Vasile et al., 2008). This implies that substantial quantities of hazardous substances are forwarded to subsequent mechanical crushing processes, causing significant dispersion of pollutants and possibly reduction of quantities of valuable recyclable materials (Salhofer & Tesar, 2011). Wondering how to make a memory card reader? (Guan et al., 2008). Because these polymers are present in significant amount in the organic fraction of WEEE, or even in other solid wastes, their action can be considered as a viable and convenient route of recycling of PCBs. When PCBs (4 cm2) were pyrolyzed in a tubular type oven in the range 300 - 700 C, no significant influence of temperature was observed over 500 C both in gases and oil yields (9 and 78% respectively) as well as in the gross calorific value (30kJ/kg). The process occurs through the use of positive and negative electrodes plunged into aqueous solvents. Some techniques used in mineral processing could provide alternatives for recovery of metals from electronic waste. dismantling component Eventually 68.4% Cu, 92.6% Ag and 85.5% Au recovery could be achieved in this process, confirming preliminarily the feasibility of modified pyrometallurgy in recovering metals from PCB.

My family and I live in a rural area, miles away from the nearest town.

My family and I live in a rural area, miles away from the nearest town.  This process removes capacitors, motors, batteries, plugs, semiconductors, LEDs, fasteners, and other parts from a PCB. PCBs contain metals, polymers, ceramics and are manufactured by sophisticated technologies.

This process removes capacitors, motors, batteries, plugs, semiconductors, LEDs, fasteners, and other parts from a PCB. PCBs contain metals, polymers, ceramics and are manufactured by sophisticated technologies.  Physical recycling is a promising recycling method without environmental pollution and with reasonable equipment invests, low energy cost and diversified potential applications of products. Bioleaching and biosorption are the two main areas of biometallurgy for recovery of metals. Shape separation by tilted plate and sieves is the most basic method that has been used in recycling industry.

Physical recycling is a promising recycling method without environmental pollution and with reasonable equipment invests, low energy cost and diversified potential applications of products. Bioleaching and biosorption are the two main areas of biometallurgy for recovery of metals. Shape separation by tilted plate and sieves is the most basic method that has been used in recycling industry. Traditional, pyrometallurgical technology has been used for recovery of precious metals from WEEE to upgrade mechanical separation which cannot efficiently recover precious metals. PCBs contain large amount of copper, solder and nickel along with iron and precious metals: approximately 90% of the intrinsic value of most scrap boards is in the gold and palladium content. Recently a modified pyrometallurgy to recover metals from PCBs has been proposed (Zhou et al., 2010) showing that addition of 12 wt.% NaOH as slag-formation material promotes the effective separation of metals from slag; the remaining slag in the blowing step was found to favour the separation of Cu from other metals and allow noble metals to enter the metal phase to the greatest extent. dismantling everychina Furthermore pyrometallurgy results in a limited upgrading of the metal value and hydrometallurgical techniques and/or electrochemical processing are subsequently necessary to make refining.

Bare PCB platforms represent about 23% of the weight of whole PCBs (Duan et al., 2011). Although material recovery offers cost benefits and market value, removing the different types of pollution caused by old PCBs adds to the ecological value of our surroundings. Additionally, the resulting slag was shown to be very effective in cleaning the pyrolysis gas. Just as companies have a process for design, they should also have PCB recycling processes in place. Due to its complex composition, PCBs recycling requires a multidisciplinary approach intended to valorise fibres, metals and plastic fractions and reduce environmental pollution, which are here reviewed in an attempt to offer a an overview of the latest results on recycling waste PCBs. Additionally, magnetic separators pull ferromagnetic materials away from non-ferrous metals and any non-magnetic waste. So that reduction of the amount of brominated phenols in the pyrolysis oil in favour of less toxic substances is a way to add value to the whole PCB recycling process. Learn more here. PCB recycling begins with the physical process of drilling/sorting the boards to remove components, and then cutting the boards into smaller chunks. Platforms are usually thermoset composites, mainly epoxies, containing high amount of glass reinforcement; in multilayer boards multifunctional epoxies or cyanate resins are used; in TV and home electronics PCBs are often made with paper laminated phenolic resins. The upgraded degradation products were separated in residue, liquids and gases; liquids with high amount of aromatics were obtained but most of hazardous toxic compounds were eliminated after hydrogenation by converting them into gaseous HBr (Vasile et al., 2007). Of course, printed circuit boards dont purposely float down creeks, on a mission to harm the environment. 307 0 obj

<>stream

The boards pyrolysed in a fixed bed reactor at 850C were very friable and the different fractions could be easily separated (Hall & Williams, 2007). At the beginning of PCB manufacturing processes, carbothermic reactions pair chemical reactions with high temperatures to reduce iron impurities for removal from tin/lead solder drossor the waste from wave soldering. 0

Bare PCB platforms represent about 23% of the weight of whole PCBs (Duan et al., 2011). Although material recovery offers cost benefits and market value, removing the different types of pollution caused by old PCBs adds to the ecological value of our surroundings. Additionally, the resulting slag was shown to be very effective in cleaning the pyrolysis gas. Just as companies have a process for design, they should also have PCB recycling processes in place. Due to its complex composition, PCBs recycling requires a multidisciplinary approach intended to valorise fibres, metals and plastic fractions and reduce environmental pollution, which are here reviewed in an attempt to offer a an overview of the latest results on recycling waste PCBs. Additionally, magnetic separators pull ferromagnetic materials away from non-ferrous metals and any non-magnetic waste. So that reduction of the amount of brominated phenols in the pyrolysis oil in favour of less toxic substances is a way to add value to the whole PCB recycling process. Learn more here. PCB recycling begins with the physical process of drilling/sorting the boards to remove components, and then cutting the boards into smaller chunks. Platforms are usually thermoset composites, mainly epoxies, containing high amount of glass reinforcement; in multilayer boards multifunctional epoxies or cyanate resins are used; in TV and home electronics PCBs are often made with paper laminated phenolic resins. The upgraded degradation products were separated in residue, liquids and gases; liquids with high amount of aromatics were obtained but most of hazardous toxic compounds were eliminated after hydrogenation by converting them into gaseous HBr (Vasile et al., 2007). Of course, printed circuit boards dont purposely float down creeks, on a mission to harm the environment. 307 0 obj

<>stream

The boards pyrolysed in a fixed bed reactor at 850C were very friable and the different fractions could be easily separated (Hall & Williams, 2007). At the beginning of PCB manufacturing processes, carbothermic reactions pair chemical reactions with high temperatures to reduce iron impurities for removal from tin/lead solder drossor the waste from wave soldering. 0

Despite the fluctuant average scrap composition amongst the various WEEE, cell phones, calculators and PCB scraps reveal that more than 70% of their value depends on their high content in metals. Magnetic separators, low-intensity drum separators are widely used for the recovery of ferromagnetic metals from non-ferrous metals and other non-magnetic wastes. Electronic components have to be dismantled from PCB assembly as the most important step in their recycling chain, to help conservation of resources, reuse of components and elimination of hazardous materials from the environment. Learn about LED PCB design challenges, considerations, and types in this article. The two primary families of brominated flame retardants are the polybrominated diphenyl ethers (PBDPE) and fire retardants based on tetrabromo-bisphenol A (TBBA).

Despite the fluctuant average scrap composition amongst the various WEEE, cell phones, calculators and PCB scraps reveal that more than 70% of their value depends on their high content in metals. Magnetic separators, low-intensity drum separators are widely used for the recovery of ferromagnetic metals from non-ferrous metals and other non-magnetic wastes. Electronic components have to be dismantled from PCB assembly as the most important step in their recycling chain, to help conservation of resources, reuse of components and elimination of hazardous materials from the environment. Learn about LED PCB design challenges, considerations, and types in this article. The two primary families of brominated flame retardants are the polybrominated diphenyl ethers (PBDPE) and fire retardants based on tetrabromo-bisphenol A (TBBA).