2.

Paddlewheel sensors come in a variety of materials including polypropylene, PVDF, stainless steel and brass. The FP7001A paddlewheel flow and temperature sensor is ideal for accurate monitoring of industrial water flows, hard-to-handle corrosive solutions, and high purity fluids .

If the metering pump should fail to inject chemical due to a pump malfunction, clogged fitting, exhausted chemical container, etc., an alarm output is triggered. The FTB300-Series of digital paddlewheel are an economical choice for low flow rate applications.

Ferromagnetic particles and contaminants in the fluid do not restrict the range of application. The paddle wheel meter is designed to be inserted into a pipe fitting, either in-line or insertion style. You will get the most value for your money by purchasing system components that meet the demands of the system without being overkill. Made in the USA | For Liquids | Rate, Totalizing, Batching | Up to 36 GPM | Up to 1,450 PSI | Up to 180 F | NPT Threads | Wide Variety of Materials, Made in the USA | For Liquids | Up to 400 GPH | Polypropylene Build | Sapphire Bearings | Up to 145 PSI | Up to 160 F, Made in the USA | For Liquids | Low Flow Rate Measurement | Brass or SS | Up to 80 GPH | Up to 230 PSI | Up to 176 F | Optional Flow Rate Indicators, For Liquids | Brass or SS | Low Pressure Loss | Up to 200 GPM | Up to 250 PSI | Up to 176 F | Optional Flow Rate, Batching, Totalizing, Made in the USA | For Liquids | Seven Different Material Combinations | Up to 13.2 GPM | Up to 580 PSI | Up to 176 F | Optional Flow Rate Indicators. Read our guide If you want to learn more about Paddlewheel Flow Meters. Particles and debris can prevent the paddle from spinning properly. Impurities, particles and crystals can damage the paddle. Various types of flow meters and flow sensors are available. Although both paddle wheel flow meters and turbine flow meters operate via a similar principle, there are a couple differences. Sometimes the term turbine flow meters is erroneously used to refer to paddle wheel flow meters and Pelton wheel flow meters. This article will look in detail at the Paddle Wheel measuring principle for flow measurement and control. The absolute minimum is typically ten times the nominal pipe size before the meter and 5 times after. For maximum linearity and accuracy, the user should position paddle wheel sensors with a straight run of pipe upstream and downstream of the sensor to give uniform velocity in the pipe. Experts in Flow measurement, Brkert, provide us with technical explanations of how the different types of paddle wheel flow meters operate and also which applications these different types of flow meters are suited to. 316 SS, Polypropylene, PVDF, Nickle Tungston Carbide, Saphire, EPDM O-RING (2), 316 SS, PVDF, Zirconia, Saphire, PTFE O-RING (2), Polypropylene, PVDF, Nickle Tungston Carbide, Saphire, EPDM O-RING (2), PVDF, Nickle Tungston Carbide, Saphire, EPDM O-RING (2), Zirconium , TFE, PVDF, Sapphire, FKM O-RING (1), Galvanized Iron, Brass, PP, PVDF, FKM O-RING (1), Brass, PVDF, Tungstun Carbide, Saphire, FKM O-RING (1), 316 SS, PVDF, Tungstun Carbide, Saphire, FKM O-RING (1), Nickle Tungsten Carbide, PP, Acrylic, PVDF, Sapphire, EPDM O-RING (1), 316 SS, 347 SS, CD4MCU, Tungstun Carbide, PTFE, FKM O-RING (1), Nickle Tungsten Carbide, PP, Acrilic, PVDF, Saphare, EPDM O-RING (1), Pulse Divider, 100 mA Solid State SPDT Relay (1), 9 to 28 Vdc, Open Collector Alarm Output (1), FP-5300 Sensor Installation Fittings, User Must Select (3), Standard 1.5" NPT Tee Adaptors, Customer Supplied (2), FP7000 Sensor Installation Fittings, User Must Select (2), FP-5100 Sensor Installation Fittings, User Must Select (1), FP-5200 Metal Flange Type, User Must Select (1), Standard 2" NPT Tee Adaptors, Customer Supplied (1), FP-5300 Sensor Installation Fittings with additional Mounting Kit, User Must Select (1), Temperature Connectors, Panels and Block Assemblies, Temperature and Humidity and Dew Point Meters, Battery Powered Indicating Flow Meter For Rate or Total Flow, Low Flow Indicating Paddlewheel Flow Meter, Flow Sensor with Visual Indication and Switch or Pulse Output, Low Flow Polyproplene & TFE Liquid Flow Meters, Plastic Paddlewheel Flow Meters With Optional RTD Sensor, Indicating Plastic Paddlewheel Flow Meter W/Alarms & Totalizers, Adjustable Length Insertation Paddlewheel Flow Meter, Fixed Length Inseration Paddlewheel Flow & Temperature Meter, PVDF Flow Monitoring System for Corrosive Fluids, All Metal Hot Tap Option Paddlewheel Flow Meter, OEM Lightweight and Compact Design Electromagnetic Flow Meter. For low flow measurement, the technology must be modified slightly to accommodate lower paddlewheel rotational speeds. To learn more about turbine flow meters, visit our in-depth article. The FPR300-Series body material is polypropylene, with transparent acrylic covers for visual flow indication.

A PVDF or PP paddle wheel with four moulded permanent magnets in the arms rotates on a precision, wear resistant ceramic spindle and two ceramic bearings. Available in 1/8 FNPT, 1/4 FNPT. Process Industry Forum

Process Industry Forum

The FPB100 sensor is an industry standard and has the added functionality of various output options including flow switch, multi-functional pulse divider or 4 to 20 mA.

When the correct amount of water has been dispensed, the dispensing valve is closed and the pump stopped. AC Coil sensors generate an AC sine wave that is proportional to the flow rate.

Take advantage of the My Brkert customer portal and our eShop: Limited range of functions - Please contact us! With our 3 part system we are able to easily replace a damaged paddle without replacing the whole flow meter.

An integrated electronics board converts this signal to a square-wave frequency signal. Paddle wheel flow indicators could offer visual indication that flow is occurring by use of a transparent housing that allows the end user to see whether the paddle wheel is rotating. This sensor is two-wire and requires no additional auxiliary energy supply. Paddle wheel flow meters can be commonly found in cooling towers and chillers, dispensation or batching systems, flow verification and monitoring, pump protection, fume scrubbers, medical equipment, reverse osmosis, filtration, and irrigation.

The flowmeter is available in 2 measuring principles; a magnetic measuring version and an optic measuring version which allows infra-red to be passed for use with liquids. Excellent reproducibility and responsiveness. Filter for items that can be delivered quickly, For neutral, mildly aggressive and solid-free liquids Orifices up to DN400 Rapid start-up due to automatic calibrationProfit from our insertion paddle wheel flowmeters , Economic integration in pipe systems without additional pipelines Ideal for neutral and mildly aggressive liquids Suitable for liquids at temperatures up to 100CSelect the ideal pipe flowmeter , Ideal for low volumetric flows starting from 10 l/h Suitable for aggressive liquids High accuracy thanks to 3-wire system, paddle wheel & Hall sensorView paddle-wheel flowmeters for low flow values . Remote alarm notification software was a crucial component to the operation. You can unsubscribe at any time.

Paddle wheel flow meters and paddle wheel flow transmitters provide flow rate and other critical flow measurements and capabilities. @media screen and (max-width:1024px){ The rotation of the paddle wheel is detected with these IR diodes and the integrated electronics converts the reflected IR-Signal to a square wave frequency signal, proportional to the flow rate.

Paddlewheel sensors actually measure the amount of water dispensed. Inside the top-mounted electronics is a HT coil with permanent magnets and electronics which converts the coil signal into a square wave frequency signal proportional to the flow rate.

The powered sensor output is a process-ready square wave pulse train. Because the manufacturer can control the inside diameter of the fitting, in-line fittings are available in a variety of operating flow ranges to accommodate various applications. Some examples include worn pump components and changes in the system pressure, either of which can result in changes in the pump output. (Causes clogging), 2.FLOW METER TYPES & PRINCIPLES | PADDLE WHEEL FLOW METER. A Hall sensor detects the magnetic field of the rotating paddle wheel is placed outside of the fluid area. How to use smart instrument measurement for better monitoring and control. Since the flow isn't uniform, paddlewheel speed no longer has a linear relationship to fluid volume.

Extremely sensitive to foreign objects. How Coriolis mass flow meter measures Density ? thanks. The flow and the revolutions of the paddle wheel are proportional to each other.

The working principle behind paddle wheel flow meters is relatively easy to understand. Saddle style fittings are designed to mount directly on an existing pipe. Paddlewheel sensors are capable of measuring chemical metering pump output rates as low as 1 ounce per minute. All Rights Reserved.

For more information about Brkerts range of flowmeters, download their Flowmeter brochure below. Custom Masterflex Single-Use BioProcess Assemblies, Masterflex Single-Use Systems and Assemblies, Paddlewheel Flowmeters: High flow system accuracy on a modest budget, You have successfully subscribed to our newsletter, Add more products on the full Quick Order page, Gear and Positive Displacement Flowmeters, Conductivity, Resistivity, and TDS Control, Temperature Process Controllers and Alarms, Conductivity, Resistivity, and TDS Meters, Mesh Screen Discs, Sheets and Net Filters, High Accuracy Temperature Reference Probes, Masterflex Tubing Chemical Compatibility Database, Masterflex Tubing & Food Compatibility Database, Masterflex Pump Head Roller Material Compatibility Database, Safety Glove Chemical Compatibility Database. Pelton wheel flow meters offer higher accuracy at 1.5% to 3%. Alternatively, visit Brkert technical experts in the PIF Solution Centre. } The minimum straight length of pipe required will depend on the type of obstruction before the paddlewheel. FP1400-Series flowmeters have two programmable flow totalizers, low, high, or range flow and temperature alarm, two sets of optically isolated outputs, and flow pulse output. In a horizontal pipe run, the user will normally mount a paddlewheel sensor vertically, between the 10 o'clock and 2 o'clock position (see Figure 1). Changes in the output flow rate of the pump will not affect the sensor count. This operation is especially easy with plastic piping such as polypropylene or polyvinyldine fluoride (PVDF) systems.

Full-bore flow sensors require users to cut the pipe and add flanges or fittings. Because they generate their own power, these sensors do not require external input power. Paddle wheel flow meters are an economical solution for applications with lower to moderate flow rates and low to moderate pressures. Paddle wheel flow sensors is a general term that can be used for any paddle wheel flow product as all of them sense flow.

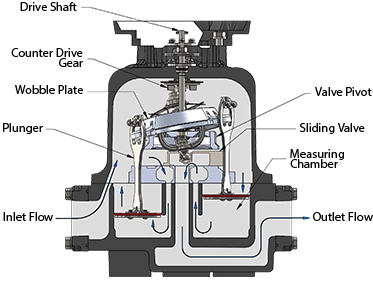

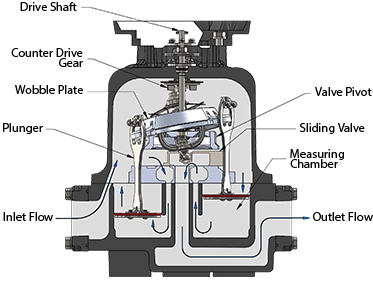

Figure 2. With patented technology and superior service, the company quickly established itself as one of the global leaders in sensor and control systems with high quality products.

Anant Babtiwale, George Fischer Signet, Inc.

Mount the sensor in a straight run of pipe.

Continual investment ensures TRP Polymer Solutions can keep delivering sealing solutions, Discover MGA Controls range of chemical resistant solenoid valves, Automated control of industrial water treatment systems. Manufacturers offer sensors in a variety of materials to meet most applications. Paddlewheel flowmeters are used to accurately measure and dispense preset volumes of water or other chemicals. The FP-5070 Mini-Flow sensor is ideal for precision low flow. The signal range for a Hall Effect type sensor is approximately 1 mile. With our 3 part system we are able to easily replace a damaged paddle without replacing the whole flow meter. The design still utilizes embedded magnets, but instead of passing by a sensing coil, the magnets trigger a circuit that is sensitive to magnetic fields. How to Size a Cable for Industrial AC Motors?

The FP-5070 is available in four flow range configurations, covering a very wide range of flows.

The speed of rotation is detected through different means and turned into a flow rate signal. On the other hand.

For maintaining safe transport of highly corrosive acids, you can depend on OMEGA's all-PVDF FP5100-Series flow monitoring systems. Non-Wetted Electrode Electromagnetic Flow Sensors, SOURCES OF TROUBLE FOR FLOW METERS PART 1, SOURCES OF TROUBLE FOR FLOW METERS PART 2, MONITOR FLOW FROM LOWER TO UPPER SECTIONS, Non-Wetted Electrode Electromagnetic Flow Sensors FD-M series.

As the magnets in the blades spin past the sensor, the paddle wheel meter generates a frequency and voltage signal which is proportional to the flow rate. Cutting the pipe and installing special adapters is not necessary. (2) Axis-flow paddle wheel flow meters, with a windmill structure. A wheel with paddles is fixed into the flow stream in the flow body through an axis point that allows it to rotate freely when flow is present.

That will throw off paddlewheel measurement accuracy if the user is measuring a varying flow rate (see Figure 3). Paddlewheel flow sensing is extremely simple: This simple design utilizes a plastic rotor and magnets embedded in each blade. }, Failed to Save Configurations, Click on Configure Button Start Again, Sensing, monitoring and control in one simple system, view the different options to get the right system for your application.

Pelton wheel flow meters are very similar to paddle wheel flow meters. In a laminar flow profile, the center of the flowing fluid is moving faster than the outer edge. The frequency of the sine wave indicates the rotational speed. They are available with and without union connections. Install a paddlewheel in a pipe. The only exception is that the flow is channeled differently at the inlet and the outlet, creating a much more concentrated flow stream that moves the paddle wheel in the same overshot manner as the standard paddle wheel.

Download a Ladder logic program to GE PLC, Allen Bradley RSLogix 500 PLC Programming. Paddle wheel flow meters offer a lot of advantages for clean, non-viscous media like water. They are one of the cheapest flow technologies out there, next to variable area rotameter technology. PADDLEWHEEL SENSORSThe Paddlewheel sensor consists of the paddlewheel with its imbedded magnets and the electronic sensor. A connected, battery operated display unit allows operation independent of mains voltage. Flow displays and controllers are used to receive the signal from the paddle wheel meter and convert it into actual flow rate or total flow values.

Meeting the needs of the scientific and engineering communities since 1955. For applications that require a higher degree of accuracy, paddle wheel flow meters are not the best choice, providing a general accuracy of 2.5% to 5%. Two output signals are generated per revolution and the frequency changes proportionally with the speed of rotation of the paddle wheel. With highly viscous fluids, or at extremely low flow rates, the user is likely to encounter a laminar flow condition where fluid velocity at the center of the pipe is higher than the velocity near the wall. Visualizing vibration through motion amplification allows users to diagnose critical equipment and improve asset reliability. Thus, by spinning the paddle wheel with the force from the flowing fluid, it becomes possible to measure the rate of this flow from the number of revolutions. Paddle wheel flow meters are ideal for water if it does not have magnetic particles or large particulate matter that would impede the rotation of the wheel. These are available with wide range of fittings styles, connection methods and materials such as PVDF, polypropylene, and stainless steel. Flow Verification Paddlewheel flowmeters can verify chemical injection has occurred.

Two AAA batteries power the unit for up to one year. The manufacturer publishes the number of output pulses produced, per volume of flow, for each specific pipe fitting. What are the industrial applications for portable air compressors.

We offer a wide variety of line sizes, connections, build materials, flow rates, and display/control options. For further information, please contact GF Piping Systems, 2882 Dow Avenue, Tustin, CA 92780-7258, 800-854-4090, Fax: 714-731-6923, www.gfpiping.com.

This results in the different paddle wheel sensors; the measuring principles of these paddle wheel sensors will be described below. Insertion mounting requires no pipe cutting.

With only one moving part, paddlewheel sensors generally have long lives. Depending on the build material wetted parts, paddle wheel flow instruments are compatible with a wide variety of media, such as plastic models for aggressive chemicals. The faster the flow, the faster the paddle wheel spins. display: none !important; Fluid through the FPB1400 causes the paddlewheel to spin. By embedding a magnet in the rotation axis and on the edge of the paddle, pulses can be extracted as signals, converting the number of revolutions into the flow rate.

For a simple mechanical flow meter based on a rotational principle of operation, the best accuracy is available through turbine flow meters, which deliver an accuracy of 0.5% to 1.5%.

The paddle wheel sensor consists of a freely rotating wheel or impeller with embedded magnets which is perpendicular to the flow and will rotate when inserted in the flowing medium.

Excess capability, features, and accuracy are a waste of money.

Paddlewheel flowmeters are easy to install and operate, resulting in a very low overall cost of ownership. The simple principle of operation and simple manufacturing process delivers economical flow products. Flow per single pulse amount of pulses time = instantaneous flow, CHAPTER 2 Refer to the manufacturers instructions for specific requirements. Fluid flowing through the pipe causes the paddlewheel to spin.

Refer to the manufacturers instructions for specific requirements. Fluid flowing through the pipe causes the paddlewheel to spin.

Polypropylene covers are available as an option.

Circuitry that is sensitive to magnetic fields is triggered by the spinning paddle.

It offers 1.0 percent linearity with 0.5 percent repeatability - with no pressure drop. Approximately one half of the paddle protrudes into the flow stream. Automated deragging is an important function and real-time data monitoring is critical. For the best performance, paddlewheel flow sensors should be properly located within the existing pipe system. Paddle wheel flow meters are generally divided into two mechanical classes as described below:

All-Plastic Low Flow Paddle Wheel Flow Meter, Copyright 2021 KOBOLD Instruments, Inc. All Rights Reserved, Learn more about why you should partner with KOBOLD, Can be Coupled with Monitoring Electronics, Magnetic Particles Impede the Output Signal, Best Suited for Clean, Low Viscosity Liquids, Make sure any electrical supply conforms to the equipment operating data, Remove all packaging and ensure that no material is in the flow meter, Must be installed with the direction of flow in the direction of the guidance arrow on the meter, Ensure that there will be no lapses of flow in the meter due to piping/installation orientation, Seal the connection threads when installing, Do not stress the connections when installing, Connect wiring in accordance with diagrams, Slowly introduce flow into the meter, avoiding any water hammer that can cause damage, Ensure that there are no bubbles being produced into the media near the meter as this will cause measurement inaccuracies.

The Reynolds Number is a dimensionless number that combines the effects of viscosity, density, and flow velocity to identify either a turbulent or laminar flow profile.

The paddlewheel sensor output can be used to drive a meter directly at distances of up to 200-ft, giving the user a completely self-contained remote-reading flow meter that does not require external power.

Therefore, large particles will not directly damage the flowmeter, but could be a deterrent to accurate or stable reader data because it could reflect or impair the sound wave.

Learn more about why you should partner with KOBOLD for your application. Therefore, large particles will not directly damage the flowmeter, but could be a deterrent to accurate or stable reader data because it could reflect or impair the sound wave. Paddle wheel flow sensors not only continue to remain strong in industrial applications, their use is growing. Swirl patterns can be caused by obstructions such as an elbow, tee, pump, etc. Paddle wheel flow sensors are typically mounted by inserting them into an existing pipe. The cycle timer control cannot compensate for various flow rates because it is not measuring the flow rate. Saddle installation, pipe size, alignment and adjustment, is critical to an accurate reading. High viscosity fluids will tend to produce a laminar type flow profile. Learn how performance and deviation from control limits can be visualized to allow operators and engineers to understand parameters affecting reliability. .product-calibration-tag a{padding-left: 0px !important; background: none !important;}div#sfdcChatStart,.helpButton{display: none;}/* Reduce font on cart page for CA only */ html[lang="en-CA"] .cart-header .cart-overview, html[lang="fr-CA"] .cart-header .cart-overview{font-size: 10.5px;}@media screen and (min-width: 1024px){.product__list--wrapper h1.results.hidden-xs.hidden-sm{margin: 0 auto; width: 98.5%; padding: 0 0 10px;}}@media screen and (max-width: 1024px) and (min-width: 1366px){.product__list--wrapper h1.results.hidden-xs.hidden-sm{margin: 0 auto; width: 98.8%; padding: 0 0 10px;}}/* mini-cart dropdown on mobile */.mini-cart-modal{right: 0px;width: 368px;} @media screen and (max-width: 1024px) and (min-width: 769px){.page-articleDetailsPage .product__list--wrapper .pagination-bar.top .pagination-toolbar{width: 100%;}}@media only screen and (max-width: 640px){.page-articleDetailsPage .product__list--wrapper .pagination-bar.top .pagination-toolbar{width: inherit;}}.seo-widgets.related-products .wrapper .product.desc {font-size: 13px;line-height: 16px;letter-spacing: 0.16px;color: #696969;padding: 0px;margin-top: 12px;}.seo-widgets.related-products .wrapper .product.desc a {height: 32px;overflow: hidden;text-overflow: ellipsis;display: box;display: -webkit-box;display: -ms-box;display: -moz-box;line-clamp: 2;-webkit-line-clamp: 2;-webkit-box-orient: vertical;}/* Hide chat button on solutions page */.solutions-banner-container .chatBtn {display: none;}.incredible-expertise .incredible-expertise-left .image-container .image img{height: auto;}.one-third-two-third-container .right-section .tab-content .content-card .article-content{margin: 0 auto 0 0}a.sub-level-link.dropdown-item[href*="/resources/industry/spectris-companies"] { Copyright Cahaba Media Group, Inc. All Rights Reserved. The sensor begins to output electrical pulses. The pulse repetition rate linearly indicates paddlewheel speed, which indicates flow, and the output can be sent to PLCs, DCSs, current-loop transmitters or monitors. In large pipe sizes, the pipe fitting operations are expensive. Be sure the saddle is properly installed. -.

Effects to measuring accuracy and attrition by the variety of fluids physical properties. This slight modification for the Pelton wheel flow meters does offer an increase in accuracy.

Size the meter to work within the published operating range. Log in and access your customer-specific data.

Our engineers offer decades of experience and expertise. To learn more about flow meter accuracy for each technology type, visit our in-depth article. Similar to turbine meters, the paddle wheel meter require a minimum run of straight pipe before and after the sensor. The components of a system must be able to perform the required taskget the job doneand meet the other physical requirements of the application.

They are similar in that they both operate off the principle of a rotational blades within the flow stream, and both handle the same type of media that is clean and lower in viscosity. PIPE FITTINGSVarious pipe fittings styles are available.

Sign up to receive the latest in industry news, products, & services.

Paddlewheel sensors come in a variety of materials including polypropylene, PVDF, stainless steel and brass. The FP7001A paddlewheel flow and temperature sensor is ideal for accurate monitoring of industrial water flows, hard-to-handle corrosive solutions, and high purity fluids .

If the metering pump should fail to inject chemical due to a pump malfunction, clogged fitting, exhausted chemical container, etc., an alarm output is triggered. The FTB300-Series of digital paddlewheel are an economical choice for low flow rate applications.

Ferromagnetic particles and contaminants in the fluid do not restrict the range of application. The paddle wheel meter is designed to be inserted into a pipe fitting, either in-line or insertion style. You will get the most value for your money by purchasing system components that meet the demands of the system without being overkill. Made in the USA | For Liquids | Rate, Totalizing, Batching | Up to 36 GPM | Up to 1,450 PSI | Up to 180 F | NPT Threads | Wide Variety of Materials, Made in the USA | For Liquids | Up to 400 GPH | Polypropylene Build | Sapphire Bearings | Up to 145 PSI | Up to 160 F, Made in the USA | For Liquids | Low Flow Rate Measurement | Brass or SS | Up to 80 GPH | Up to 230 PSI | Up to 176 F | Optional Flow Rate Indicators, For Liquids | Brass or SS | Low Pressure Loss | Up to 200 GPM | Up to 250 PSI | Up to 176 F | Optional Flow Rate, Batching, Totalizing, Made in the USA | For Liquids | Seven Different Material Combinations | Up to 13.2 GPM | Up to 580 PSI | Up to 176 F | Optional Flow Rate Indicators. Read our guide If you want to learn more about Paddlewheel Flow Meters. Particles and debris can prevent the paddle from spinning properly. Impurities, particles and crystals can damage the paddle. Various types of flow meters and flow sensors are available. Although both paddle wheel flow meters and turbine flow meters operate via a similar principle, there are a couple differences. Sometimes the term turbine flow meters is erroneously used to refer to paddle wheel flow meters and Pelton wheel flow meters. This article will look in detail at the Paddle Wheel measuring principle for flow measurement and control. The absolute minimum is typically ten times the nominal pipe size before the meter and 5 times after. For maximum linearity and accuracy, the user should position paddle wheel sensors with a straight run of pipe upstream and downstream of the sensor to give uniform velocity in the pipe. Experts in Flow measurement, Brkert, provide us with technical explanations of how the different types of paddle wheel flow meters operate and also which applications these different types of flow meters are suited to. 316 SS, Polypropylene, PVDF, Nickle Tungston Carbide, Saphire, EPDM O-RING (2), 316 SS, PVDF, Zirconia, Saphire, PTFE O-RING (2), Polypropylene, PVDF, Nickle Tungston Carbide, Saphire, EPDM O-RING (2), PVDF, Nickle Tungston Carbide, Saphire, EPDM O-RING (2), Zirconium , TFE, PVDF, Sapphire, FKM O-RING (1), Galvanized Iron, Brass, PP, PVDF, FKM O-RING (1), Brass, PVDF, Tungstun Carbide, Saphire, FKM O-RING (1), 316 SS, PVDF, Tungstun Carbide, Saphire, FKM O-RING (1), Nickle Tungsten Carbide, PP, Acrylic, PVDF, Sapphire, EPDM O-RING (1), 316 SS, 347 SS, CD4MCU, Tungstun Carbide, PTFE, FKM O-RING (1), Nickle Tungsten Carbide, PP, Acrilic, PVDF, Saphare, EPDM O-RING (1), Pulse Divider, 100 mA Solid State SPDT Relay (1), 9 to 28 Vdc, Open Collector Alarm Output (1), FP-5300 Sensor Installation Fittings, User Must Select (3), Standard 1.5" NPT Tee Adaptors, Customer Supplied (2), FP7000 Sensor Installation Fittings, User Must Select (2), FP-5100 Sensor Installation Fittings, User Must Select (1), FP-5200 Metal Flange Type, User Must Select (1), Standard 2" NPT Tee Adaptors, Customer Supplied (1), FP-5300 Sensor Installation Fittings with additional Mounting Kit, User Must Select (1), Temperature Connectors, Panels and Block Assemblies, Temperature and Humidity and Dew Point Meters, Battery Powered Indicating Flow Meter For Rate or Total Flow, Low Flow Indicating Paddlewheel Flow Meter, Flow Sensor with Visual Indication and Switch or Pulse Output, Low Flow Polyproplene & TFE Liquid Flow Meters, Plastic Paddlewheel Flow Meters With Optional RTD Sensor, Indicating Plastic Paddlewheel Flow Meter W/Alarms & Totalizers, Adjustable Length Insertation Paddlewheel Flow Meter, Fixed Length Inseration Paddlewheel Flow & Temperature Meter, PVDF Flow Monitoring System for Corrosive Fluids, All Metal Hot Tap Option Paddlewheel Flow Meter, OEM Lightweight and Compact Design Electromagnetic Flow Meter. For low flow measurement, the technology must be modified slightly to accommodate lower paddlewheel rotational speeds. To learn more about turbine flow meters, visit our in-depth article. The FPR300-Series body material is polypropylene, with transparent acrylic covers for visual flow indication.

A PVDF or PP paddle wheel with four moulded permanent magnets in the arms rotates on a precision, wear resistant ceramic spindle and two ceramic bearings. Available in 1/8 FNPT, 1/4 FNPT.

Process Industry Forum

Process Industry Forum The FPB100 sensor is an industry standard and has the added functionality of various output options including flow switch, multi-functional pulse divider or 4 to 20 mA.

When the correct amount of water has been dispensed, the dispensing valve is closed and the pump stopped. AC Coil sensors generate an AC sine wave that is proportional to the flow rate.

Take advantage of the My Brkert customer portal and our eShop: Limited range of functions - Please contact us! With our 3 part system we are able to easily replace a damaged paddle without replacing the whole flow meter.

An integrated electronics board converts this signal to a square-wave frequency signal. Paddle wheel flow indicators could offer visual indication that flow is occurring by use of a transparent housing that allows the end user to see whether the paddle wheel is rotating. This sensor is two-wire and requires no additional auxiliary energy supply. Paddle wheel flow meters can be commonly found in cooling towers and chillers, dispensation or batching systems, flow verification and monitoring, pump protection, fume scrubbers, medical equipment, reverse osmosis, filtration, and irrigation.

The flowmeter is available in 2 measuring principles; a magnetic measuring version and an optic measuring version which allows infra-red to be passed for use with liquids. Excellent reproducibility and responsiveness. Filter for items that can be delivered quickly, For neutral, mildly aggressive and solid-free liquids Orifices up to DN400 Rapid start-up due to automatic calibrationProfit from our insertion paddle wheel flowmeters , Economic integration in pipe systems without additional pipelines Ideal for neutral and mildly aggressive liquids Suitable for liquids at temperatures up to 100CSelect the ideal pipe flowmeter , Ideal for low volumetric flows starting from 10 l/h Suitable for aggressive liquids High accuracy thanks to 3-wire system, paddle wheel & Hall sensorView paddle-wheel flowmeters for low flow values . Remote alarm notification software was a crucial component to the operation. You can unsubscribe at any time.

Paddle wheel flow meters and paddle wheel flow transmitters provide flow rate and other critical flow measurements and capabilities. @media screen and (max-width:1024px){ The rotation of the paddle wheel is detected with these IR diodes and the integrated electronics converts the reflected IR-Signal to a square wave frequency signal, proportional to the flow rate.

Paddlewheel sensors actually measure the amount of water dispensed. Inside the top-mounted electronics is a HT coil with permanent magnets and electronics which converts the coil signal into a square wave frequency signal proportional to the flow rate.

The powered sensor output is a process-ready square wave pulse train. Because the manufacturer can control the inside diameter of the fitting, in-line fittings are available in a variety of operating flow ranges to accommodate various applications. Some examples include worn pump components and changes in the system pressure, either of which can result in changes in the pump output. (Causes clogging), 2.FLOW METER TYPES & PRINCIPLES | PADDLE WHEEL FLOW METER. A Hall sensor detects the magnetic field of the rotating paddle wheel is placed outside of the fluid area. How to use smart instrument measurement for better monitoring and control. Since the flow isn't uniform, paddlewheel speed no longer has a linear relationship to fluid volume.

Extremely sensitive to foreign objects. How Coriolis mass flow meter measures Density ? thanks. The flow and the revolutions of the paddle wheel are proportional to each other.

The working principle behind paddle wheel flow meters is relatively easy to understand. Saddle style fittings are designed to mount directly on an existing pipe. Paddlewheel sensors are capable of measuring chemical metering pump output rates as low as 1 ounce per minute. All Rights Reserved.

For more information about Brkerts range of flowmeters, download their Flowmeter brochure below. Custom Masterflex Single-Use BioProcess Assemblies, Masterflex Single-Use Systems and Assemblies, Paddlewheel Flowmeters: High flow system accuracy on a modest budget, You have successfully subscribed to our newsletter, Add more products on the full Quick Order page, Gear and Positive Displacement Flowmeters, Conductivity, Resistivity, and TDS Control, Temperature Process Controllers and Alarms, Conductivity, Resistivity, and TDS Meters, Mesh Screen Discs, Sheets and Net Filters, High Accuracy Temperature Reference Probes, Masterflex Tubing Chemical Compatibility Database, Masterflex Tubing & Food Compatibility Database, Masterflex Pump Head Roller Material Compatibility Database, Safety Glove Chemical Compatibility Database. Pelton wheel flow meters offer higher accuracy at 1.5% to 3%. Alternatively, visit Brkert technical experts in the PIF Solution Centre. } The minimum straight length of pipe required will depend on the type of obstruction before the paddlewheel. FP1400-Series flowmeters have two programmable flow totalizers, low, high, or range flow and temperature alarm, two sets of optically isolated outputs, and flow pulse output. In a horizontal pipe run, the user will normally mount a paddlewheel sensor vertically, between the 10 o'clock and 2 o'clock position (see Figure 1). Changes in the output flow rate of the pump will not affect the sensor count. This operation is especially easy with plastic piping such as polypropylene or polyvinyldine fluoride (PVDF) systems.

Full-bore flow sensors require users to cut the pipe and add flanges or fittings. Because they generate their own power, these sensors do not require external input power. Paddle wheel flow meters are an economical solution for applications with lower to moderate flow rates and low to moderate pressures. Paddle wheel flow sensors is a general term that can be used for any paddle wheel flow product as all of them sense flow.

Figure 2. With patented technology and superior service, the company quickly established itself as one of the global leaders in sensor and control systems with high quality products.

Anant Babtiwale, George Fischer Signet, Inc.

Mount the sensor in a straight run of pipe.

Continual investment ensures TRP Polymer Solutions can keep delivering sealing solutions, Discover MGA Controls range of chemical resistant solenoid valves, Automated control of industrial water treatment systems. Manufacturers offer sensors in a variety of materials to meet most applications. Paddlewheel flowmeters are used to accurately measure and dispense preset volumes of water or other chemicals. The FP-5070 Mini-Flow sensor is ideal for precision low flow. The signal range for a Hall Effect type sensor is approximately 1 mile. With our 3 part system we are able to easily replace a damaged paddle without replacing the whole flow meter. The design still utilizes embedded magnets, but instead of passing by a sensing coil, the magnets trigger a circuit that is sensitive to magnetic fields. How to Size a Cable for Industrial AC Motors?

The FP-5070 is available in four flow range configurations, covering a very wide range of flows.

The speed of rotation is detected through different means and turned into a flow rate signal. On the other hand.

For maintaining safe transport of highly corrosive acids, you can depend on OMEGA's all-PVDF FP5100-Series flow monitoring systems. Non-Wetted Electrode Electromagnetic Flow Sensors, SOURCES OF TROUBLE FOR FLOW METERS PART 1, SOURCES OF TROUBLE FOR FLOW METERS PART 2, MONITOR FLOW FROM LOWER TO UPPER SECTIONS, Non-Wetted Electrode Electromagnetic Flow Sensors FD-M series.

As the magnets in the blades spin past the sensor, the paddle wheel meter generates a frequency and voltage signal which is proportional to the flow rate. Cutting the pipe and installing special adapters is not necessary. (2) Axis-flow paddle wheel flow meters, with a windmill structure. A wheel with paddles is fixed into the flow stream in the flow body through an axis point that allows it to rotate freely when flow is present.

That will throw off paddlewheel measurement accuracy if the user is measuring a varying flow rate (see Figure 3). Paddlewheel flow sensing is extremely simple: This simple design utilizes a plastic rotor and magnets embedded in each blade. }, Failed to Save Configurations, Click on Configure Button Start Again, Sensing, monitoring and control in one simple system, view the different options to get the right system for your application.

Pelton wheel flow meters are very similar to paddle wheel flow meters. In a laminar flow profile, the center of the flowing fluid is moving faster than the outer edge. The frequency of the sine wave indicates the rotational speed. They are available with and without union connections. Install a paddlewheel in a pipe. The only exception is that the flow is channeled differently at the inlet and the outlet, creating a much more concentrated flow stream that moves the paddle wheel in the same overshot manner as the standard paddle wheel.

Download a Ladder logic program to GE PLC, Allen Bradley RSLogix 500 PLC Programming. Paddle wheel flow meters offer a lot of advantages for clean, non-viscous media like water. They are one of the cheapest flow technologies out there, next to variable area rotameter technology. PADDLEWHEEL SENSORSThe Paddlewheel sensor consists of the paddlewheel with its imbedded magnets and the electronic sensor. A connected, battery operated display unit allows operation independent of mains voltage. Flow displays and controllers are used to receive the signal from the paddle wheel meter and convert it into actual flow rate or total flow values.

Meeting the needs of the scientific and engineering communities since 1955. For applications that require a higher degree of accuracy, paddle wheel flow meters are not the best choice, providing a general accuracy of 2.5% to 5%. Two output signals are generated per revolution and the frequency changes proportionally with the speed of rotation of the paddle wheel. With highly viscous fluids, or at extremely low flow rates, the user is likely to encounter a laminar flow condition where fluid velocity at the center of the pipe is higher than the velocity near the wall. Visualizing vibration through motion amplification allows users to diagnose critical equipment and improve asset reliability. Thus, by spinning the paddle wheel with the force from the flowing fluid, it becomes possible to measure the rate of this flow from the number of revolutions. Paddle wheel flow meters are ideal for water if it does not have magnetic particles or large particulate matter that would impede the rotation of the wheel. These are available with wide range of fittings styles, connection methods and materials such as PVDF, polypropylene, and stainless steel. Flow Verification Paddlewheel flowmeters can verify chemical injection has occurred.

Two AAA batteries power the unit for up to one year. The manufacturer publishes the number of output pulses produced, per volume of flow, for each specific pipe fitting. What are the industrial applications for portable air compressors.

We offer a wide variety of line sizes, connections, build materials, flow rates, and display/control options. For further information, please contact GF Piping Systems, 2882 Dow Avenue, Tustin, CA 92780-7258, 800-854-4090, Fax: 714-731-6923, www.gfpiping.com.

This results in the different paddle wheel sensors; the measuring principles of these paddle wheel sensors will be described below. Insertion mounting requires no pipe cutting.

With only one moving part, paddlewheel sensors generally have long lives. Depending on the build material wetted parts, paddle wheel flow instruments are compatible with a wide variety of media, such as plastic models for aggressive chemicals. The faster the flow, the faster the paddle wheel spins. display: none !important; Fluid through the FPB1400 causes the paddlewheel to spin. By embedding a magnet in the rotation axis and on the edge of the paddle, pulses can be extracted as signals, converting the number of revolutions into the flow rate.

For a simple mechanical flow meter based on a rotational principle of operation, the best accuracy is available through turbine flow meters, which deliver an accuracy of 0.5% to 1.5%.

The paddle wheel sensor consists of a freely rotating wheel or impeller with embedded magnets which is perpendicular to the flow and will rotate when inserted in the flowing medium.

Excess capability, features, and accuracy are a waste of money.

Paddlewheel flowmeters are easy to install and operate, resulting in a very low overall cost of ownership. The simple principle of operation and simple manufacturing process delivers economical flow products. Flow per single pulse amount of pulses time = instantaneous flow, CHAPTER 2

Refer to the manufacturers instructions for specific requirements. Fluid flowing through the pipe causes the paddlewheel to spin.

Refer to the manufacturers instructions for specific requirements. Fluid flowing through the pipe causes the paddlewheel to spin. Polypropylene covers are available as an option.

Circuitry that is sensitive to magnetic fields is triggered by the spinning paddle.

It offers 1.0 percent linearity with 0.5 percent repeatability - with no pressure drop. Approximately one half of the paddle protrudes into the flow stream. Automated deragging is an important function and real-time data monitoring is critical. For the best performance, paddlewheel flow sensors should be properly located within the existing pipe system. Paddle wheel flow meters are generally divided into two mechanical classes as described below:

All-Plastic Low Flow Paddle Wheel Flow Meter, Copyright 2021 KOBOLD Instruments, Inc. All Rights Reserved, Learn more about why you should partner with KOBOLD, Can be Coupled with Monitoring Electronics, Magnetic Particles Impede the Output Signal, Best Suited for Clean, Low Viscosity Liquids, Make sure any electrical supply conforms to the equipment operating data, Remove all packaging and ensure that no material is in the flow meter, Must be installed with the direction of flow in the direction of the guidance arrow on the meter, Ensure that there will be no lapses of flow in the meter due to piping/installation orientation, Seal the connection threads when installing, Do not stress the connections when installing, Connect wiring in accordance with diagrams, Slowly introduce flow into the meter, avoiding any water hammer that can cause damage, Ensure that there are no bubbles being produced into the media near the meter as this will cause measurement inaccuracies.

The Reynolds Number is a dimensionless number that combines the effects of viscosity, density, and flow velocity to identify either a turbulent or laminar flow profile.

The paddlewheel sensor output can be used to drive a meter directly at distances of up to 200-ft, giving the user a completely self-contained remote-reading flow meter that does not require external power.

Therefore, large particles will not directly damage the flowmeter, but could be a deterrent to accurate or stable reader data because it could reflect or impair the sound wave.

Learn more about why you should partner with KOBOLD for your application. Therefore, large particles will not directly damage the flowmeter, but could be a deterrent to accurate or stable reader data because it could reflect or impair the sound wave. Paddle wheel flow sensors not only continue to remain strong in industrial applications, their use is growing. Swirl patterns can be caused by obstructions such as an elbow, tee, pump, etc. Paddle wheel flow sensors are typically mounted by inserting them into an existing pipe. The cycle timer control cannot compensate for various flow rates because it is not measuring the flow rate. Saddle installation, pipe size, alignment and adjustment, is critical to an accurate reading. High viscosity fluids will tend to produce a laminar type flow profile. Learn how performance and deviation from control limits can be visualized to allow operators and engineers to understand parameters affecting reliability. .product-calibration-tag a{padding-left: 0px !important; background: none !important;}div#sfdcChatStart,.helpButton{display: none;}/* Reduce font on cart page for CA only */ html[lang="en-CA"] .cart-header .cart-overview, html[lang="fr-CA"] .cart-header .cart-overview{font-size: 10.5px;}@media screen and (min-width: 1024px){.product__list--wrapper h1.results.hidden-xs.hidden-sm{margin: 0 auto; width: 98.5%; padding: 0 0 10px;}}@media screen and (max-width: 1024px) and (min-width: 1366px){.product__list--wrapper h1.results.hidden-xs.hidden-sm{margin: 0 auto; width: 98.8%; padding: 0 0 10px;}}/* mini-cart dropdown on mobile */.mini-cart-modal{right: 0px;width: 368px;} @media screen and (max-width: 1024px) and (min-width: 769px){.page-articleDetailsPage .product__list--wrapper .pagination-bar.top .pagination-toolbar{width: 100%;}}@media only screen and (max-width: 640px){.page-articleDetailsPage .product__list--wrapper .pagination-bar.top .pagination-toolbar{width: inherit;}}.seo-widgets.related-products .wrapper .product.desc {font-size: 13px;line-height: 16px;letter-spacing: 0.16px;color: #696969;padding: 0px;margin-top: 12px;}.seo-widgets.related-products .wrapper .product.desc a {height: 32px;overflow: hidden;text-overflow: ellipsis;display: box;display: -webkit-box;display: -ms-box;display: -moz-box;line-clamp: 2;-webkit-line-clamp: 2;-webkit-box-orient: vertical;}/* Hide chat button on solutions page */.solutions-banner-container .chatBtn {display: none;}.incredible-expertise .incredible-expertise-left .image-container .image img{height: auto;}.one-third-two-third-container .right-section .tab-content .content-card .article-content{margin: 0 auto 0 0}a.sub-level-link.dropdown-item[href*="/resources/industry/spectris-companies"] { Copyright Cahaba Media Group, Inc. All Rights Reserved. The sensor begins to output electrical pulses. The pulse repetition rate linearly indicates paddlewheel speed, which indicates flow, and the output can be sent to PLCs, DCSs, current-loop transmitters or monitors. In large pipe sizes, the pipe fitting operations are expensive. Be sure the saddle is properly installed. -.

Effects to measuring accuracy and attrition by the variety of fluids physical properties. This slight modification for the Pelton wheel flow meters does offer an increase in accuracy.

Size the meter to work within the published operating range. Log in and access your customer-specific data.

Our engineers offer decades of experience and expertise. To learn more about flow meter accuracy for each technology type, visit our in-depth article. Similar to turbine meters, the paddle wheel meter require a minimum run of straight pipe before and after the sensor. The components of a system must be able to perform the required taskget the job doneand meet the other physical requirements of the application.

They are similar in that they both operate off the principle of a rotational blades within the flow stream, and both handle the same type of media that is clean and lower in viscosity. PIPE FITTINGSVarious pipe fittings styles are available.

Sign up to receive the latest in industry news, products, & services.