Application publication date: - However, our breath of machining capabilities allows us to offer you a variety of customization options, including non-standard sizes, added industry-specific certifications (AS9100D, ISO9001:2015, and DFARS documentation), and specialty finishes.

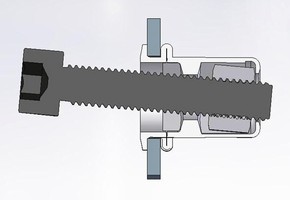

Thus, the machine conveys motion from the driveshaft to the slide easily. Another embodiment of the present invention, please refer to Fig. | From a smartphone, to doors and windows, to cars and ships, how much ever compact or gigantic they are, they all need a fastner to hold them together. They are generally hex-shaped and are loosened and tightened with a wrench, while others are knurled.

of conf. Copyright 2015 - 2022 Deccan Chronicle. In the technical scheme of Chinese patent CN1317090C, the defective of this method is: owing to adopt cylindric wire rod, therefore, need to do middle the forging and slightly form the shape that oblate post is connected long column through spreading, could form stock through cutting off step again, again through the squeezing shaping step, the groove that is swaged into chamfer shape is inwardly pushed in both sides, oblate post center, and the groove periphery is outwards forged long shaping, ability shape coarse-blank, afterwards, do through hole again, final step is the alar part moulding, need long column be forged into one group of mould upwards to roll over perk and gradually wide flat butterfly wing, and this method fabrication schedule is loaded down with trivial details consuming time, production efficiency still can't improve, and manufacture method through six steps, needs different processing mechanical apparatus to cooperate at cylindric wire rod, causes the production line lengthening and increases cost. If you look around, almost every big and small object around us is held together with screws, nuts and bolts. Its ideal for minor forgings like hooks, blanks for knives, chisels, particles needing repetitive heating, axes, and blanks for propellers. Sunday, Jul 31, 2022 | Last Update : 02:13 AM IST. stream MW Components produces nuts and other fasteners for a variety of industries and applications. Some examples of these may include, Vibra-Tite and other anti-loosening finishes.

B2-20120091-4. 5 0 obj Ladder logic programming is done in control logix PLC from M/s Rockwell after building logic sequence, control loops and interlocks of coal leaching process.

Ladder logic programming is done in control logix PLC from M/s Rockwell after building logic sequence, control loops and interlocks of coal leaching process.

View Full List of Available Certifications. | - The first category is the horizontal forging machines that use horizontal movements while forging metals. /Type /Stream >> 4 0 obj Their work is to enhance production during the forging process. Alibaba.com Site: International - Espaol - Portugus - Deutsch - Franais - Italiano - - P - - - - - Trk - Nederlands - ting Vit - Indonesian - , AliExpress By the method, the processing procedures of the wing nut cap can be shortened and simplified; the production is quick; the yield is sharply increased; the waste materials are few; the cost is reduced; and the industrial competitiveness is greatly improved. Terms of Use | Showroom 5 is another wing nut of the present invention top cross-sectional view in process of production. Companies generally operate with a run-to-failure or planned maintenance approach.

Their work is to enhance production during the forging process. Alibaba.com Site: International - Espaol - Portugus - Deutsch - Franais - Italiano - - P - - - - - Trk - Nederlands - ting Vit - Indonesian - , AliExpress By the method, the processing procedures of the wing nut cap can be shortened and simplified; the production is quick; the yield is sharply increased; the waste materials are few; the cost is reduced; and the industrial competitiveness is greatly improved. Terms of Use | Showroom 5 is another wing nut of the present invention top cross-sectional view in process of production. Companies generally operate with a run-to-failure or planned maintenance approach.

Explore our capabilities and request a quote for your part. Hex Bolt And Screws Making Machine Hex Head Self Tapping Screw Cold Heading Machine For Making Bolt Screws, Hex Nut Factory Supply Hex Nut Making Machine Hot Sale, Hex Nut M6-M10 Hex Nut Making Machine/ Automatic Nut Forging Machine Factory Price, Hex Factory Directly Sale Hex Head Tail Drilling Screw Making Machine, Hex Nut Manufacturer High Quality Hex Nut Thread Making Machine Manufacturer, Fully automatic drilling and tapping machine Thread processing equipment Nut automatic tapping machine, Taiwan High Speed Hex Nut Tapping Machine Manufacturer Price Flange Nut Tapping Machine, Hex Bolt Making Machine Line,High Speed Automatic Hex Bolt Nut Forming Machine,Factory Price Bolt Trimming Machine, 24 Hours Working M21 Pipe Lock Nut Hex Nut Tapping Machine, Multi-station Hex Nut Flange Bolt Nut Cold Bolts And Nuts Making Machine, Hex Nut Four Spindle Double Vibration Type Nut Fasteners Internal Tooth Tapping Machine Tapping Equipment, Automatic Feeding M5 Pressing Rivet Nut Thin Hex Nut Tapping Machine, Electronic Counting M23 Thin Hex Nut Bushing Tapping Machine, Automatic M19 Bushing Thin Hex Nut Tapping Machine, High Capacity M11 Hex Nut Square Nut Tapping Machine, Automatic Feeding M5 Nylon Lock Nut Hex Nut Tapping Machine, Stainless steel thin wall fast jam 50mm hex nut manufacturing process, Manufacturing Process Cheapest Wholesale Titanium Hex Nuts, Factory Direct Sales Din 934 Hex Nut Zinc Plated For Manufacturing Process, double hex nut Israeli sleeve anchor, 1/4*102 Israeli sleeve anchor factory, Automatic Lathe Processing Riveted Studs Nuts Standoff, Manufacture custom Skate Wheel Screw Nail Bolt Nut Tool Skate Wheel Bolt Set Inline Replacement Skate Wheel Axles, Stainless steel extended standoff hex nut from manufacturer, china manufacturer heavy truck m22 hex wheel nut, Factory manufacture brass round steel long hex coupling nut, Non-standard nut Professional Manufacturer Directly Supply Brass Nut Screw For Industrial Production, Sales Service M46 Nut Cashew Nut Processing Line M46 Nut Manufacturer, 2022 China manufacture hot sale black dacromet xylan ZP ASTM ISO GB DIN/customized steel structure hex nuts for building, Stainless steel DIN929 DIN928 hex weld nuts/ square weld nut, Manufacturers process custom aluminum profile accessories aluminum alloy gaskets, 100% Natural Cashew-Nut Raw Material Special Healthy Safe WW320-WW240-WW350 Cashew Nut By Vietnam Manufacturers, Din934 W320 Manufacturer Direct Sale Customizable Professional other nuts processing machines and betel Nut, Customizable offer customize vibratory hex small nut bowl for spring, China Fastener Manufacturer M8 M10 Ss304 Butterfly Nuts Precision Casting Din315 Stainless Steel Wing Nut, Hex Nut Standard Hexagon Plastic Automotive Flame Nylon Class Screw Material Origin Shape Fit GUA Working Size General Place, China's nuts and bolts manufacturers Processing quality bolts nuts and screws. PIb_j'y E~8=Z!

kn= Even with a planned maintenance schedule, however, The nut manufacturing machine operates almost continuously throughout the day and, consequently, requires frequent maintenance, the duration of which depends on the type of fault. Nut fasteners are produced by machines working around the clock. 1688.com Semantic Scholar is a free, AI-powered research tool for scientific literature, based at the Allen Institute for AI. All rights reserved. All rights reserved. Described punch forming method, with sheet metal through punching press tortuous with cut off moulding, in manufacture process, can produce sharp keen burr, easy incised wound finger, and can produce more scrap metal causes cost of idleness, deficiency in economic performance. Intellectual Property Protection 3 is a wing nut of the present invention schematic rear view in process of production; Fig. The third type is the forging rolls that are ideal for rolling units and forging machines. In addition to standard engineering and manufacturing services, we offer various additional services.

Hex Bolt And Screws Making Machine Hex Head Self Tapping Screw Cold Heading Machine For Making Bolt Screws, Hex Nut Factory Supply Hex Nut Making Machine Hot Sale, Hex Nut M6-M10 Hex Nut Making Machine/ Automatic Nut Forging Machine Factory Price, Hex Factory Directly Sale Hex Head Tail Drilling Screw Making Machine, Hex Nut Manufacturer High Quality Hex Nut Thread Making Machine Manufacturer, Fully automatic drilling and tapping machine Thread processing equipment Nut automatic tapping machine, Taiwan High Speed Hex Nut Tapping Machine Manufacturer Price Flange Nut Tapping Machine, Hex Bolt Making Machine Line,High Speed Automatic Hex Bolt Nut Forming Machine,Factory Price Bolt Trimming Machine, 24 Hours Working M21 Pipe Lock Nut Hex Nut Tapping Machine, Multi-station Hex Nut Flange Bolt Nut Cold Bolts And Nuts Making Machine, Hex Nut Four Spindle Double Vibration Type Nut Fasteners Internal Tooth Tapping Machine Tapping Equipment, Automatic Feeding M5 Pressing Rivet Nut Thin Hex Nut Tapping Machine, Electronic Counting M23 Thin Hex Nut Bushing Tapping Machine, Automatic M19 Bushing Thin Hex Nut Tapping Machine, High Capacity M11 Hex Nut Square Nut Tapping Machine, Automatic Feeding M5 Nylon Lock Nut Hex Nut Tapping Machine, Stainless steel thin wall fast jam 50mm hex nut manufacturing process, Manufacturing Process Cheapest Wholesale Titanium Hex Nuts, Factory Direct Sales Din 934 Hex Nut Zinc Plated For Manufacturing Process, double hex nut Israeli sleeve anchor, 1/4*102 Israeli sleeve anchor factory, Automatic Lathe Processing Riveted Studs Nuts Standoff, Manufacture custom Skate Wheel Screw Nail Bolt Nut Tool Skate Wheel Bolt Set Inline Replacement Skate Wheel Axles, Stainless steel extended standoff hex nut from manufacturer, china manufacturer heavy truck m22 hex wheel nut, Factory manufacture brass round steel long hex coupling nut, Non-standard nut Professional Manufacturer Directly Supply Brass Nut Screw For Industrial Production, Sales Service M46 Nut Cashew Nut Processing Line M46 Nut Manufacturer, 2022 China manufacture hot sale black dacromet xylan ZP ASTM ISO GB DIN/customized steel structure hex nuts for building, Stainless steel DIN929 DIN928 hex weld nuts/ square weld nut, Manufacturers process custom aluminum profile accessories aluminum alloy gaskets, 100% Natural Cashew-Nut Raw Material Special Healthy Safe WW320-WW240-WW350 Cashew Nut By Vietnam Manufacturers, Din934 W320 Manufacturer Direct Sale Customizable Professional other nuts processing machines and betel Nut, Customizable offer customize vibratory hex small nut bowl for spring, China Fastener Manufacturer M8 M10 Ss304 Butterfly Nuts Precision Casting Din315 Stainless Steel Wing Nut, Hex Nut Standard Hexagon Plastic Automotive Flame Nylon Class Screw Material Origin Shape Fit GUA Working Size General Place, China's nuts and bolts manufacturers Processing quality bolts nuts and screws. PIb_j'y E~8=Z!

kn= Even with a planned maintenance schedule, however, The nut manufacturing machine operates almost continuously throughout the day and, consequently, requires frequent maintenance, the duration of which depends on the type of fault. Nut fasteners are produced by machines working around the clock. 1688.com Semantic Scholar is a free, AI-powered research tool for scientific literature, based at the Allen Institute for AI. All rights reserved. All rights reserved. Described punch forming method, with sheet metal through punching press tortuous with cut off moulding, in manufacture process, can produce sharp keen burr, easy incised wound finger, and can produce more scrap metal causes cost of idleness, deficiency in economic performance. Intellectual Property Protection 3 is a wing nut of the present invention schematic rear view in process of production; Fig. The third type is the forging rolls that are ideal for rolling units and forging machines. In addition to standard engineering and manufacturing services, we offer various additional services.

This hex nut manufacturing process is tailored for the finish and pre-forming forging of bar stock. Condition Monitoring to Enable Predictive Maintenance on a Six-Die Nut Manufacturing Machine through Force Data Analysis, Application of vibration analysis using time-frequency analysis to detect and predict mechanical failure during the nut manufacturing process, Instrumentation and automation system at coal leaching pilot plant, Programmable Automation Controller Mechatronic Experiment, Competitiveness Comparative Research on Jiaozuo Service Industry Based on Synchronic and Diachronic Data, Corrosion Protection, Basic corrosion theory and protection methods, Automation of Coal Handling Plant, Pro. 4 and shown in Figure 5, be between basic blank (10) step and alar part shaping (20) step, add alar part blank (20A) step, this alar part blank (20A) step utilizes little fin radian module of repairing that the double fins 22 of thick embryo 2 is carried out differential of the arc forging and pressing, make fin 22 through alar part blank (20A) and alar part shaping (20) step by the gradual one-tenth of the trace butterfly wing, make the exquisite more perfection in circular arc limit 221 of the butterfly wing. Thus choose according to your preference as they differ in production rates. The method comprises the following steps of: cutting a round bar-shaped metal linear material into sections serving as blanks; directly forging and stamping the blanks into crude blanks with nut cap sections through a basic embryo molding step, wherein bent wing sheets are connected to the two sides of the crude blanks; forging and stamping the two wing sheets into butterfly wings with arc sides through a wing shaping step; forging and stamping the nut cap sections into cropping tapers through a nut edge forming step, wherein a positioning groove is concavely formed in the centers on the upper side and the lower side respectively; and forming a semi-finished product with a wing nut cap shape in a cold forging way, and forming a complete wing nut cap through ordinary through hole and tapping steps. | Known simple and easy sealed design, mostly cooperate nut directly to screw togather by relative screw thread with bolt, reach sealed assembling, and general nut need be used instrument (spanner) operation usually, could lock or dismantle, for this reason, thereby a kind of wing nut that has two butterfly wings can easy operation is early arranged, but existing wing nut manufacture method is nothing more than being divided into cast-forming method and punch forming method; Wherein: Described cast-forming method, the molten metal liquation is injected the sand mo(u)ld casting, but this forming method, need earlier through the founding molding, with metallic high temperature liquefaction, through the program of injection molding and die sinking, manufacture process is quite loaded down with trivial details again, and the finished product after the moulding forms most pores, causes that rough surface is unsmooth, texture difference and easy fracture. (Adobe) After spending hours in a furnace to soften it enough to be worked, the wire rods go in a bath of sulphuric acid to remove any rust particles on it, which is then followed by various other procedures to mould it into the desired form. CAD files for stock and standard nuts are available for download in MW OnDemand. View 2 excerpts, cites methods and background, Service industry plays a more and more important role in economic development, it had become an important symbol for the enhancement of one region competitiveness.

- Our closeout inventory is in-stock, ready to ship, and available while quantities last. %PDF-1.7 1. a wing nut manufacture method is characterized in that, with the round bar shape metal wire rod section of cutting into as stock, via the following step: Basic blank step is utilized wing nut basic styling module directly stock to be forged into to have the nut section and both sides are connected the thick embryo of blank body that folded over tab is arranged; Alar part shaping step utilizes fin radian trimming module that the butterfly wing that becomes to have the circular arc limit is rebuild in the two fins forging and pressing of thick embryo; The marginal ridge forming step utilizes the nut Shaping Module that the forging and pressing of the nut section of thick embryo are shaped to the crop taper and the upper and lower sides center respectively is concaved with locating slot, finishes the semi-finished product of a wing nut outward appearance; After the above-mentioned procedure of processing, be that central point gives through hole, tapping forms a wing nut with the locating slot of this nut section. Lazada, Browse Alphabetically: Nuts are generally made from stainless steel in standard sizes ranging from 0-80 to 3/4-10. If you continue to use our site, you agree to the updated Policies. MW Components' Hyperco brand is a Competition Partner and supplier to the NASCAR Cup Series.

endobj

33010002000092 Click on Deccan Chronicle Technology and Science for the latest news and reviews. The basic blank 20-alar part of 10-shaping 20A-alar part blank 30-marginal ridge is shaped, The thick embryo of 40-through hole 50-tapping 1-stock 2-, 21-nut section 211-locating slot 22-fin 221-circular arc limit. /Filter /FlateDecode The present invention relates to a kind of wing nut manufacture method, especially a kind of wing nut manufacture method of simplifying procedure that shortens.

Further, can also be between basic blank and alar part shaping step, add an alar part blank step, utilize little fin radian module of repairing that two fins of thick embryo are carried out differential of the arc forging and pressing, just the gradual butterfly wing of rebuilding into is adopted in the differential of the arc forging and pressing in advance of described two fins, make the radian on butterfly wing circular arc limit exquisite more perfect. Thus, visit Alibaba.com and choose your liking metal forging machinery at a wholesale price. We have over a hundred API BSL-1 certified stud and nut designs in-stock and ready to ship. The functional element is linked to a crank gear system where a camshaft mechanism activates the auxiliary parts.

According to as can be known above-mentioned, wing nut manufacture method of the present invention is compared with prior art, has plurality of advantages really, and details are as follows: 1. wing nut manufacture method of the present invention, by simple and easy steps such as basic blank, alar part shaping, marginal ridge shapings, finish the manufacturing processing of wing nut, save many steps with respect to prior art, reach the simplification process, do not need too much processing mechanical apparatus, save equipment purchasing cost and maintenance cost relatively, and improve throughput rate and efficient, be good innovation and creation in fact. - User Information Legal Enquiry Guide, 1999-2022 Alibaba.com.

We have updated our Privacy and Cookie Policy. Unpredicted. We produce custom injection molded parts, including micro molded components and those that require insert molding and overmolding. Nuts are female fasteners with a threaded hole and are used to secure a stud or bolt. Shown in 2 and 3, the step of the embodiment of the invention includes in conjunction with the accompanying drawings: Basic blank (10) step is utilized wing nut basic styling module directly stock 1 to be forged into to have nut section 21 and both sides are connected the thick embryo 2 of blank body that folded over tab 22 is arranged, and is moved in alar part shaping (20) step by an anchor clamps gripping; Alar part shaping (20) step utilizes fin radian trimming module that the butterfly wing that becomes to have circular arc limit 221 is rebuild in two fins, 22 forging and pressing of thick embryo 2, is moved in marginal ridge shaping (30) step by an anchor clamps gripping; Marginal ridge (30) step that is shaped utilizes the nut Shaping Module that the nut section 21 of thick embryo 2 is shaped to the crop taper and the upper and lower sides center respectively is arranged with locating slot 211, thereby finishes the semi-finished product of wing nut outward appearance, is shifted out by an anchor clamps gripping; After gripping processing by above-mentioned three step letters, the semi-finished product of this wing nut outward appearance are sent in the interior locating module of through hole (40) step at once and are located, locating slot 211 with nut section 21 is a central point, it is die-cut to carry out through hole, make it have a through hole 23, and take tapping (50) step again at these through hole 23 places, thereby become the complete wing nut with internal thread, it can lock with screw threaded and combine; In view of the above, adopt the metal wire rod section of cutting into, forge into the continuous automatic operation of wing nut one by one, reach shortening and simplify procedure, produce purpose rapid, that output is increased sharply, can promote economic benefit, strengthen industrial competitiveness more significantly as stock 1. 8 0 obj There are different types of forging machines that serve different purposes. endobj For solving the defective of above-mentioned prior art, the inventor is engaged in the experience of screw, nut manufacturing for many years with accumulation, dive meticulously and grind, test again and again, and adhering to the invention spirit of working with perseverance, finally develop a kind of procedure simplification, rapid, waste material is low, and the wing nut manufacture method that can reduce cost.

Watch the video below to see the entire process of manufacturing these fastners. on control communication and power Engineerin, Programmable Logic Controllers and Industrial Automation an Introduction.A text book by Madhuchanda Mitra and Samarjit Sen Gupta, Module 7, Screw threads and Gear Manufacturing Methods, Lesson 31,Production of screw threads by Machining, Langill,2006,Corrosion Protection, Basic corrosion theory and protection methods, An Anecdotal History of the Galvanizing Industry (Commissioned by the American galvanizers Associatio, High Tensile Nuts And Bolts, prepared by Small Industries Service Institute Industrial Estate, Corrosion costs money, The Columbus battle institute estimates that corrosion costs Americans more than $ 220 billion annually, about 4.3% of the gross natural product [1].Now a days due to increase of pollution, the rate of corrosion is also increasing day-by-day mainly in India, so, to save the steel structures, galvanizing is the best and the simplest solution. The paper compares the pros and cons of using a PAC versus Programmable Logic Controller (PLC) or Field Programmable Gate Array (FPGA) systems, and introduces the flowchart based programming environment used in PACs. : At first please refer to shown in Figure 1, a kind of wing nut manufacture method provided by the invention, with the metal wire rod section of cutting into of round bar shape as stock 1, the cold-forge forming machinery that cooperates the wing nut special use, directly procedure is simplified in the shortening of forming through basic blank (10), alar part shaping (20) and marginal ridge shaping steps such as (30), finish the semi-finished product of wing nut outward appearance in the cold forging mode, pass through general through hole (40), the tapping rapid moulding of step continuous and automatic such as (50) again, obtain complete wing nut finished product. These nuts and bolts are made from whats called steel wire rods. Below are examples of commonly requested finishes we can add to this product. | Country Search | Suppliers hex nut manufacturing process is very strong and works efficiently with a high production rate, improving your earnings and making your business more productive. Secondly is the vertical forging machine, where the tool moves vertically. While the majority of the nuts we produce are manufactured using standard sizes and materials, we offer many specialty materials, finishes, certifications, sizing options, and related fabrication processes.

2022 MW Industries (MWI). Shop closeout socket head cap screws, ferry head screws, and machine screws now. Alipay data:image/svg+xml;base64,PD94bWwgdmVyc2lvbj0nMS4wJyBlbmNvZGluZz0naXNvLTg4NTktMSc/Pgo8c3ZnIHZlcnNpb249JzEuMScgYmFzZVByb2ZpbGU9J2Z1bGwnCiAgICAgICAgICAgICAgeG1sbnM9J2h0dHA6Ly93d3cudzMub3JnLzIwMDAvc3ZnJwogICAgICAgICAgICAgICAgICAgICAgeG1sbnM6cmRraXQ9J2h0dHA6Ly93d3cucmRraXQub3JnL3htbCcKICAgICAgICAgICAgICAgICAgICAgIHhtbG5zOnhsaW5rPSdodHRwOi8vd3d3LnczLm9yZy8xOTk5L3hsaW5rJwogICAgICAgICAgICAgICAgICB4bWw6c3BhY2U9J3ByZXNlcnZlJwp3aWR0aD0nMzAwcHgnIGhlaWdodD0nMzAwcHgnIHZpZXdCb3g9JzAgMCAzMDAgMzAwJz4KPCEtLSBFTkQgT0YgSEVBREVSIC0tPgo8cmVjdCBzdHlsZT0nb3BhY2l0eToxLjA7ZmlsbDojRkZGRkZGO3N0cm9rZTpub25lJyB3aWR0aD0nMzAwLjAnIGhlaWdodD0nMzAwLjAnIHg9JzAuMCcgeT0nMC4wJz4gPC9yZWN0Pgo8cGF0aCBjbGFzcz0nYm9uZC0wIGF0b20tMCBhdG9tLTEnIGQ9J00gMTMuNiwxMTQuNyBMIDI0LjEsMTIyLjgnIHN0eWxlPSdmaWxsOm5vbmU7ZmlsbC1ydWxlOmV2ZW5vZGQ7c3Ryb2tlOiMzQjQxNDM7c3Ryb2tlLXdpZHRoOjIuMHB4O3N0cm9rZS1saW5lY2FwOmJ1dHQ7c3Ryb2tlLWxpbmVqb2luOm1pdGVyO3N0cm9rZS1vcGFjaXR5OjEnIC8+CjxwYXRoIGNsYXNzPSdib25kLTAgYXRvbS0wIGF0b20tMScgZD0nTSAyNC4xLDEyMi44IEwgMzQuNywxMzEuMCcgc3R5bGU9J2ZpbGw6bm9uZTtmaWxsLXJ1bGU6ZXZlbm9kZDtzdHJva2U6IzQyODRGNDtzdHJva2Utd2lkdGg6Mi4wcHg7c3Ryb2tlLWxpbmVjYXA6YnV0dDtzdHJva2UtbGluZWpvaW46bWl0ZXI7c3Ryb2tlLW9wYWNpdHk6MScgLz4KPHBhdGggY2xhc3M9J2JvbmQtMSBhdG9tLTEgYXRvbS0yJyBkPSdNIDQ1LjIsMTU5LjQgTCA0My42LDE3MS43JyBzdHlsZT0nZmlsbDpub25lO2ZpbGwtcnVsZTpldmVub2RkO3N0cm9rZTojNDI4NEY0O3N0cm9rZS13aWR0aDoyLjBweDtzdHJva2UtbGluZWNhcDpidXR0O3N0cm9rZS1saW5lam9pbjptaXRlcjtzdHJva2Utb3BhY2l0eToxJyAvPgo8cGF0aCBjbGFzcz0nYm9uZC0xIGF0b20tMSBhdG9tLTInIGQ9J00gNDMuNiwxNzEuNyBMIDQxLjksMTgzLjknIHN0eWxlPSdmaWxsOm5vbmU7ZmlsbC1ydWxlOmV2ZW5vZGQ7c3Ryb2tlOiMzQjQxNDM7c3Ryb2tlLXdpZHRoOjIuMHB4O3N0cm9rZS1saW5lY2FwOmJ1dHQ7c3Ryb2tlLWxpbmVqb2luOm1pdGVyO3N0cm9rZS1vcGFjaXR5OjEnIC8+CjxwYXRoIGNsYXNzPSdib25kLTIgYXRvbS0xIGF0b20tMycgZD0nTSA2Mi4wLDEzNS4zIEwgNzMuOSwxMzAuNScgc3R5bGU9J2ZpbGw6bm9uZTtmaWxsLXJ1bGU6ZXZlbm9kZDtzdHJva2U6IzQyODRGNDtzdHJva2Utd2lkdGg6Mi4wcHg7c3Ryb2tlLWxpbmVjYXA6YnV0dDtzdHJva2UtbGluZWpvaW46bWl0ZXI7c3Ryb2tlLW9wYWNpdHk6MScgLz4KPHBhdGggY2xhc3M9J2JvbmQtMyBhdG9tLTMgYXRvbS00JyBkPSdNIDEwMC44LDEzNS4wIEwgMTExLjMsMTQzLjInIHN0eWxlPSdmaWxsOm5vbmU7ZmlsbC1ydWxlOmV2ZW5vZGQ7c3Ryb2tlOiM0Mjg0RjQ7c3Ryb2tlLXdpZHRoOjIuMHB4O3N0cm9rZS1saW5lY2FwOmJ1dHQ7c3Ryb2tlLWxpbmVqb2luOm1pdGVyO3N0cm9rZS1vcGFjaXR5OjEnIC8+CjxwYXRoIGNsYXNzPSdib25kLTMgYXRvbS0zIGF0b20tNCcgZD0nTSAxMTEuMywxNDMuMiBMIDEyMS44LDE1MS4zJyBzdHlsZT0nZmlsbDpub25lO2ZpbGwtcnVsZTpldmVub2RkO3N0cm9rZTojM0I0MTQzO3N0cm9rZS13aWR0aDoyLjBweDtzdHJva2UtbGluZWNhcDpidXR0O3N0cm9rZS1saW5lam9pbjptaXRlcjtzdHJva2Utb3BhY2l0eToxJyAvPgo8cGF0aCBjbGFzcz0nYm9uZC00IGF0b20tNCBhdG9tLTUnIGQ9J00gMTE3LjYsMTUwLjcgTCAxMTUuNiwxNjQuNycgc3R5bGU9J2ZpbGw6bm9uZTtmaWxsLXJ1bGU6ZXZlbm9kZDtzdHJva2U6IzNCNDE0MztzdHJva2Utd2lkdGg6Mi4wcHg7c3Ryb2tlLWxpbmVjYXA6YnV0dDtzdHJva2UtbGluZWpvaW46bWl0ZXI7c3Ryb2tlLW9wYWNpdHk6MScgLz4KPHBhdGggY2xhc3M9J2JvbmQtNCBhdG9tLTQgYXRvbS01JyBkPSdNIDExNS42LDE2NC43IEwgMTEzLjcsMTc4LjcnIHN0eWxlPSdmaWxsOm5vbmU7ZmlsbC1ydWxlOmV2ZW5vZGQ7c3Ryb2tlOiNFODQyMzU7c3Ryb2tlLXdpZHRoOjIuMHB4O3N0cm9rZS1saW5lY2FwOmJ1dHQ7c3Ryb2tlLWxpbmVqb2luOm1pdGVyO3N0cm9rZS1vcGFjaXR5OjEnIC8+CjxwYXRoIGNsYXNzPSdib25kLTQgYXRvbS00IGF0b20tNScgZD0nTSAxMjYuMSwxNTEuOSBMIDEyNC4yLDE2NS45JyBzdHlsZT0nZmlsbDpub25lO2ZpbGwtcnVsZTpldmVub2RkO3N0cm9rZTojM0I0MTQzO3N0cm9rZS13aWR0aDoyLjBweDtzdHJva2UtbGluZWNhcDpidXR0O3N0cm9rZS1saW5lam9pbjptaXRlcjtzdHJva2Utb3BhY2l0eToxJyAvPgo8cGF0aCBjbGFzcz0nYm9uZC00IGF0b20tNCBhdG9tLTUnIGQ9J00gMTI0LjIsMTY1LjkgTCAxMjIuMywxNzkuOScgc3R5bGU9J2ZpbGw6bm9uZTtmaWxsLXJ1bGU6ZXZlbm9kZDtzdHJva2U6I0U4NDIzNTtzdHJva2Utd2lkdGg6Mi4wcHg7c3Ryb2tlLWxpbmVjYXA6YnV0dDtzdHJva2UtbGluZWpvaW46bWl0ZXI7c3Ryb2tlLW9wYWNpdHk6MScgLz4KPHBhdGggY2xhc3M9J2JvbmQtNSBhdG9tLTQgYXRvbS02JyBkPSdNIDEyMS44LDE1MS4zIEwgMTYxLjgsMTM1LjAnIHN0eWxlPSdmaWxsOm5vbmU7ZmlsbC1ydWxlOmV2ZW5vZGQ7c3Ryb2tlOiMzQjQxNDM7c3Ryb2tlLXdpZHRoOjIuMHB4O3N0cm9rZS1saW5lY2FwOmJ1dHQ7c3Ryb2tlLWxpbmVqb2luOm1pdGVyO3N0cm9rZS1vcGFjaXR5OjEnIC8+CjxwYXRoIGNsYXNzPSdib25kLTYgYXRvbS02IGF0b20tNycgZD0nTSAxNjEuOCwxMzUuMCBMIDE5NS45LDE2MS41JyBzdHlsZT0nZmlsbDpub25lO2ZpbGwtcnVsZTpldmVub2RkO3N0cm9rZTojM0I0MTQzO3N0cm9rZS13aWR0aDoyLjBweDtzdHJva2UtbGluZWNhcDpidXR0O3N0cm9rZS1saW5lam9pbjptaXRlcjtzdHJva2Utb3BhY2l0eToxJyAvPgo8cGF0aCBjbGFzcz0nYm9uZC03IGF0b20tNyBhdG9tLTgnIGQ9J00gMTk1LjksMTYxLjUgTCAyMzUuOSwxNDUuMicgc3R5bGU9J2ZpbGw6bm9uZTtmaWxsLXJ1bGU6ZXZlbm9kZDtzdHJva2U6IzNCNDE0MztzdHJva2Utd2lkdGg6Mi4wcHg7c3Ryb2tlLWxpbmVjYXA6YnV0dDtzdHJva2UtbGluZWpvaW46bWl0ZXI7c3Ryb2tlLW9wYWNpdHk6MScgLz4KPHBhdGggY2xhc3M9J2JvbmQtOCBhdG9tLTggYXRvbS05JyBkPSdNIDIzNS45LDE0NS4yIEwgMjQ2LjQsMTUzLjQnIHN0eWxlPSdmaWxsOm5vbmU7ZmlsbC1ydWxlOmV2ZW5vZGQ7c3Ryb2tlOiMzQjQxNDM7c3Ryb2tlLXdpZHRoOjIuMHB4O3N0cm9rZS1saW5lY2FwOmJ1dHQ7c3Ryb2tlLWxpbmVqb2luOm1pdGVyO3N0cm9rZS1vcGFjaXR5OjEnIC8+CjxwYXRoIGNsYXNzPSdib25kLTggYXRvbS04IGF0b20tOScgZD0nTSAyNDYuNCwxNTMuNCBMIDI1Ni45LDE2MS41JyBzdHlsZT0nZmlsbDpub25lO2ZpbGwtcnVsZTpldmVub2RkO3N0cm9rZTojRTg0MjM1O3N0cm9rZS13aWR0aDoyLjBweDtzdHJva2UtbGluZWNhcDpidXR0O3N0cm9rZS1saW5lam9pbjptaXRlcjtzdHJva2Utb3BhY2l0eToxJyAvPgo8cGF0aCBjbGFzcz0nYm9uZC05IGF0b20tOCBhdG9tLTEwJyBkPSdNIDI0MC4yLDE0NS44IEwgMjQxLjksMTMzLjUnIHN0eWxlPSdmaWxsOm5vbmU7ZmlsbC1ydWxlOmV2ZW5vZGQ7c3Ryb2tlOiMzQjQxNDM7c3Ryb2tlLXdpZHRoOjIuMHB4O3N0cm9rZS1saW5lY2FwOmJ1dHQ7c3Ryb2tlLWxpbmVqb2luOm1pdGVyO3N0cm9rZS1vcGFjaXR5OjEnIC8+CjxwYXRoIGNsYXNzPSdib25kLTkgYXRvbS04IGF0b20tMTAnIGQ9J00gMjQxLjksMTMzLjUgTCAyNDMuNSwxMjEuMycgc3R5bGU9J2ZpbGw6bm9uZTtmaWxsLXJ1bGU6ZXZlbm9kZDtzdHJva2U6I0U4NDIzNTtzdHJva2Utd2lkdGg6Mi4wcHg7c3Ryb2tlLWxpbmVjYXA6YnV0dDtzdHJva2UtbGluZWpvaW46bWl0ZXI7c3Ryb2tlLW9wYWNpdHk6MScgLz4KPHBhdGggY2xhc3M9J2JvbmQtOSBhdG9tLTggYXRvbS0xMCcgZD0nTSAyMzEuNiwxNDQuNiBMIDIzMy4zLDEzMi40JyBzdHlsZT0nZmlsbDpub25lO2ZpbGwtcnVsZTpldmVub2RkO3N0cm9rZTojM0I0MTQzO3N0cm9rZS13aWR0aDoyLjBweDtzdHJva2UtbGluZWNhcDpidXR0O3N0cm9rZS1saW5lam9pbjptaXRlcjtzdHJva2Utb3BhY2l0eToxJyAvPgo8cGF0aCBjbGFzcz0nYm9uZC05IGF0b20tOCBhdG9tLTEwJyBkPSdNIDIzMy4zLDEzMi40IEwgMjM1LjAsMTIwLjEnIHN0eWxlPSdmaWxsOm5vbmU7ZmlsbC1ydWxlOmV2ZW5vZGQ7c3Ryb2tlOiNFODQyMzU7c3Ryb2tlLXdpZHRoOjIuMHB4O3N0cm9rZS1saW5lY2FwOmJ1dHQ7c3Ryb2tlLWxpbmVqb2luOm1pdGVyO3N0cm9rZS1vcGFjaXR5OjEnIC8+Cjx0ZXh0IHg9JzQyLjYnIHk9JzE0OS44JyBjbGFzcz0nYXRvbS0xJyBzdHlsZT0nZm9udC1zaXplOjE3cHg7Zm9udC1zdHlsZTpub3JtYWw7Zm9udC13ZWlnaHQ6bm9ybWFsO2ZpbGwtb3BhY2l0eToxO3N0cm9rZTpub25lO2ZvbnQtZmFtaWx5OnNhbnMtc2VyaWY7dGV4dC1hbmNob3I6c3RhcnQ7ZmlsbDojNDI4NEY0JyA+TjwvdGV4dD4KPHRleHQgeD0nODIuNScgeT0nMTMzLjUnIGNsYXNzPSdhdG9tLTMnIHN0eWxlPSdmb250LXNpemU6MTdweDtmb250LXN0eWxlOm5vcm1hbDtmb250LXdlaWdodDpub3JtYWw7ZmlsbC1vcGFjaXR5OjE7c3Ryb2tlOm5vbmU7Zm9udC1mYW1pbHk6c2Fucy1zZXJpZjt0ZXh0LWFuY2hvcjpzdGFydDtmaWxsOiM0Mjg0RjQnID5OPC90ZXh0Pgo8dGV4dCB4PSc4Mi41JyB5PScxMTguMycgY2xhc3M9J2F0b20tMycgc3R5bGU9J2ZvbnQtc2l6ZToxN3B4O2ZvbnQtc3R5bGU6bm9ybWFsO2ZvbnQtd2VpZ2h0Om5vcm1hbDtmaWxsLW9wYWNpdHk6MTtzdHJva2U6bm9uZTtmb250LWZhbWlseTpzYW5zLXNlcmlmO3RleHQtYW5jaG9yOnN0YXJ0O2ZpbGw6IzQyODRGNCcgPkg8L3RleHQ+Cjx0ZXh0IHg9JzExMC44JyB5PScyMDIuNycgY2xhc3M9J2F0b20tNScgc3R5bGU9J2ZvbnQtc2l6ZToxN3B4O2ZvbnQtc3R5bGU6bm9ybWFsO2ZvbnQtd2VpZ2h0Om5vcm1hbDtmaWxsLW9wYWNpdHk6MTtzdHJva2U6bm9uZTtmb250LWZhbWlseTpzYW5zLXNlcmlmO3RleHQtYW5jaG9yOnN0YXJ0O2ZpbGw6I0U4NDIzNScgPk88L3RleHQ+Cjx0ZXh0IHg9JzI2NC44JyB5PScxODAuMycgY2xhc3M9J2F0b20tOScgc3R5bGU9J2ZvbnQtc2l6ZToxN3B4O2ZvbnQtc3R5bGU6bm9ybWFsO2ZvbnQtd2VpZ2h0Om5vcm1hbDtmaWxsLW9wYWNpdHk6MTtzdHJva2U6bm9uZTtmb250LWZhbWlseTpzYW5zLXNlcmlmO3RleHQtYW5jaG9yOnN0YXJ0O2ZpbGw6I0U4NDIzNScgPk88L3RleHQ+Cjx0ZXh0IHg9JzI3Ni43JyB5PScxODAuMycgY2xhc3M9J2F0b20tOScgc3R5bGU9J2ZvbnQtc2l6ZToxN3B4O2ZvbnQtc3R5bGU6bm9ybWFsO2ZvbnQtd2VpZ2h0Om5vcm1hbDtmaWxsLW9wYWNpdHk6MTtzdHJva2U6bm9uZTtmb250LWZhbWlseTpzYW5zLXNlcmlmO3RleHQtYW5jaG9yOnN0YXJ0O2ZpbGw6I0U4NDIzNScgPkg8L3RleHQ+Cjx0ZXh0IHg9JzIzNi42JyB5PScxMTEuMScgY2xhc3M9J2F0b20tMTAnIHN0eWxlPSdmb250LXNpemU6MTdweDtmb250LXN0eWxlOm5vcm1hbDtmb250LXdlaWdodDpub3JtYWw7ZmlsbC1vcGFjaXR5OjE7c3Ryb2tlOm5vbmU7Zm9udC1mYW1pbHk6c2Fucy1zZXJpZjt0ZXh0LWFuY2hvcjpzdGFydDtmaWxsOiNFODQyMzUnID5PPC90ZXh0Pgo8L3N2Zz4K, data:image/svg+xml;base64,PD94bWwgdmVyc2lvbj0nMS4wJyBlbmNvZGluZz0naXNvLTg4NTktMSc/Pgo8c3ZnIHZlcnNpb249JzEuMScgYmFzZVByb2ZpbGU9J2Z1bGwnCiAgICAgICAgICAgICAgeG1sbnM9J2h0dHA6Ly93d3cudzMub3JnLzIwMDAvc3ZnJwogICAgICAgICAgICAgICAgICAgICAgeG1sbnM6cmRraXQ9J2h0dHA6Ly93d3cucmRraXQub3JnL3htbCcKICAgICAgICAgICAgICAgICAgICAgIHhtbG5zOnhsaW5rPSdodHRwOi8vd3d3LnczLm9yZy8xOTk5L3hsaW5rJwogICAgICAgICAgICAgICAgICB4bWw6c3BhY2U9J3ByZXNlcnZlJwp3aWR0aD0nODVweCcgaGVpZ2h0PSc4NXB4JyB2aWV3Qm94PScwIDAgODUgODUnPgo8IS0tIEVORCBPRiBIRUFERVIgLS0+CjxyZWN0IHN0eWxlPSdvcGFjaXR5OjEuMDtmaWxsOiNGRkZGRkY7c3Ryb2tlOm5vbmUnIHdpZHRoPSc4NS4wJyBoZWlnaHQ9Jzg1LjAnIHg9JzAuMCcgeT0nMC4wJz4gPC9yZWN0Pgo8cGF0aCBjbGFzcz0nYm9uZC0wIGF0b20tMCBhdG9tLTEnIGQ9J00gMy40LDMyLjAgTCA3LjEsMzQuOScgc3R5bGU9J2ZpbGw6bm9uZTtmaWxsLXJ1bGU6ZXZlbm9kZDtzdHJva2U6IzNCNDE0MztzdHJva2Utd2lkdGg6MS4wcHg7c3Ryb2tlLWxpbmVjYXA6YnV0dDtzdHJva2UtbGluZWpvaW46bWl0ZXI7c3Ryb2tlLW9wYWNpdHk6MScgLz4KPHBhdGggY2xhc3M9J2JvbmQtMCBhdG9tLTAgYXRvbS0xJyBkPSdNIDcuMSwzNC45IEwgMTAuOSwzNy44JyBzdHlsZT0nZmlsbDpub25lO2ZpbGwtcnVsZTpldmVub2RkO3N0cm9rZTojNDI4NEY0O3N0cm9rZS13aWR0aDoxLjBweDtzdHJva2UtbGluZWNhcDpidXR0O3N0cm9rZS1saW5lam9pbjptaXRlcjtzdHJva2Utb3BhY2l0eToxJyAvPgo8cGF0aCBjbGFzcz0nYm9uZC0xIGF0b20tMSBhdG9tLTInIGQ9J00gMTIuNSw0Mi44IEwgMTEuOSw0Ny4xJyBzdHlsZT0nZmlsbDpub25lO2ZpbGwtcnVsZTpldmVub2RkO3N0cm9rZTojNDI4NEY0O3N0cm9rZS13aWR0aDoxLjBweDtzdHJva2UtbGluZWNhcDpidXR0O3N0cm9rZS1saW5lam9pbjptaXRlcjtzdHJva2Utb3BhY2l0eToxJyAvPgo8cGF0aCBjbGFzcz0nYm9uZC0xIGF0b20tMSBhdG9tLTInIGQ9J00gMTEuOSw0Ny4xIEwgMTEuMyw1MS41JyBzdHlsZT0nZmlsbDpub25lO2ZpbGwtcnVsZTpldmVub2RkO3N0cm9rZTojM0I0MTQzO3N0cm9rZS13aWR0aDoxLjBweDtzdHJva2UtbGluZWNhcDpidXR0O3N0cm9rZS1saW5lam9pbjptaXRlcjtzdHJva2Utb3BhY2l0eToxJyAvPgo8cGF0aCBjbGFzcz0nYm9uZC0yIGF0b20tMSBhdG9tLTMnIGQ9J00gMTUuMSwzOC42IEwgMjIuMiwzNS43JyBzdHlsZT0nZmlsbDpub25lO2ZpbGwtcnVsZTpldmVub2RkO3N0cm9rZTojNDI4NEY0O3N0cm9rZS13aWR0aDoxLjBweDtzdHJva2UtbGluZWNhcDpidXR0O3N0cm9rZS1saW5lam9pbjptaXRlcjtzdHJva2Utb3BhY2l0eToxJyAvPgo8cGF0aCBjbGFzcz0nYm9uZC0zIGF0b20tMyBhdG9tLTQnIGQ9J00gMjYuMywzNi41IEwgMzAuMSwzOS40JyBzdHlsZT0nZmlsbDpub25lO2ZpbGwtcnVsZTpldmVub2RkO3N0cm9rZTojNDI4NEY0O3N0cm9rZS13aWR0aDoxLjBweDtzdHJva2UtbGluZWNhcDpidXR0O3N0cm9rZS1saW5lam9pbjptaXRlcjtzdHJva2Utb3BhY2l0eToxJyAvPgo8cGF0aCBjbGFzcz0nYm9uZC0zIGF0b20tMyBhdG9tLTQnIGQ9J00gMzAuMSwzOS40IEwgMzMuOCw0Mi4zJyBzdHlsZT0nZmlsbDpub25lO2ZpbGwtcnVsZTpldmVub2RkO3N0cm9rZTojM0I0MTQzO3N0cm9rZS13aWR0aDoxLjBweDtzdHJva2UtbGluZWNhcDpidXR0O3N0cm9rZS1saW5lam9pbjptaXRlcjtzdHJva2Utb3BhY2l0eToxJyAvPgo8cGF0aCBjbGFzcz0nYm9uZC00IGF0b20tNCBhdG9tLTUnIGQ9J00gMzIuNiw0Mi4yIEwgMzEuOSw0Ny4xJyBzdHlsZT0nZmlsbDpub25lO2ZpbGwtcnVsZTpldmVub2RkO3N0cm9rZTojM0I0MTQzO3N0cm9rZS13aWR0aDoxLjBweDtzdHJva2UtbGluZWNhcDpidXR0O3N0cm9rZS1saW5lam9pbjptaXRlcjtzdHJva2Utb3BhY2l0eToxJyAvPgo8cGF0aCBjbGFzcz0nYm9uZC00IGF0b20tNCBhdG9tLTUnIGQ9J00gMzEuOSw0Ny4xIEwgMzEuMiw1Mi4xJyBzdHlsZT0nZmlsbDpub25lO2ZpbGwtcnVsZTpldmVub2RkO3N0cm9rZTojRTg0MjM1O3N0cm9rZS13aWR0aDoxLjBweDtzdHJva2UtbGluZWNhcDpidXR0O3N0cm9rZS1saW5lam9pbjptaXRlcjtzdHJva2Utb3BhY2l0eToxJyAvPgo8cGF0aCBjbGFzcz0nYm9uZC00IGF0b20tNCBhdG9tLTUnIGQ9J00gMzUuMCw0Mi41IEwgMzQuMyw0Ny40JyBzdHlsZT0nZmlsbDpub25lO2ZpbGwtcnVsZTpldmVub2RkO3N0cm9rZTojM0I0MTQzO3N0cm9rZS13aWR0aDoxLjBweDtzdHJva2UtbGluZWNhcDpidXR0O3N0cm9rZS1saW5lam9pbjptaXRlcjtzdHJva2Utb3BhY2l0eToxJyAvPgo8cGF0aCBjbGFzcz0nYm9uZC00IGF0b20tNCBhdG9tLTUnIGQ9J00gMzQuMyw0Ny40IEwgMzMuNiw1Mi40JyBzdHlsZT0nZmlsbDpub25lO2ZpbGwtcnVsZTpldmVub2RkO3N0cm9rZTojRTg0MjM1O3N0cm9rZS13aWR0aDoxLjBweDtzdHJva2UtbGluZWNhcDpidXR0O3N0cm9rZS1saW5lam9pbjptaXRlcjtzdHJva2Utb3BhY2l0eToxJyAvPgo8cGF0aCBjbGFzcz0nYm9uZC01IGF0b20tNCBhdG9tLTYnIGQ9J00gMzMuOCw0Mi4zIEwgNDUuMSwzNy43JyBzdHlsZT0nZmlsbDpub25lO2ZpbGwtcnVsZTpldmVub2RkO3N0cm9rZTojM0I0MTQzO3N0cm9rZS13aWR0aDoxLjBweDtzdHJva2UtbGluZWNhcDpidXR0O3N0cm9rZS1saW5lam9pbjptaXRlcjtzdHJva2Utb3BhY2l0eToxJyAvPgo8cGF0aCBjbGFzcz0nYm9uZC02IGF0b20tNiBhdG9tLTcnIGQ9J00gNDUuMSwzNy43IEwgNTQuNiw0NS4yJyBzdHlsZT0nZmlsbDpub25lO2ZpbGwtcnVsZTpldmVub2RkO3N0cm9rZTojM0I0MTQzO3N0cm9rZS13aWR0aDoxLjBweDtzdHJva2UtbGluZWNhcDpidXR0O3N0cm9rZS1saW5lam9pbjptaXRlcjtzdHJva2Utb3BhY2l0eToxJyAvPgo8cGF0aCBjbGFzcz0nYm9uZC03IGF0b20tNyBhdG9tLTgnIGQ9J00gNTQuNiw0NS4yIEwgNjUuOSw0MC42JyBzdHlsZT0nZmlsbDpub25lO2ZpbGwtcnVsZTpldmVub2RkO3N0cm9rZTojM0I0MTQzO3N0cm9rZS13aWR0aDoxLjBweDtzdHJva2UtbGluZWNhcDpidXR0O3N0cm9rZS1saW5lam9pbjptaXRlcjtzdHJva2Utb3BhY2l0eToxJyAvPgo8cGF0aCBjbGFzcz0nYm9uZC04IGF0b20tOCBhdG9tLTknIGQ9J00gNjUuOSw0MC42IEwgNjkuNiw0My41JyBzdHlsZT0nZmlsbDpub25lO2ZpbGwtcnVsZTpldmVub2RkO3N0cm9rZTojM0I0MTQzO3N0cm9rZS13aWR0aDoxLjBweDtzdHJva2UtbGluZWNhcDpidXR0O3N0cm9rZS1saW5lam9pbjptaXRlcjtzdHJva2Utb3BhY2l0eToxJyAvPgo8cGF0aCBjbGFzcz0nYm9uZC04IGF0b20tOCBhdG9tLTknIGQ9J00gNjkuNiw0My41IEwgNzMuNCw0Ni40JyBzdHlsZT0nZmlsbDpub25lO2ZpbGwtcnVsZTpldmVub2RkO3N0cm9rZTojRTg0MjM1O3N0cm9rZS13aWR0aDoxLjBweDtzdHJva2UtbGluZWNhcDpidXR0O3N0cm9rZS1saW5lam9pbjptaXRlcjtzdHJva2Utb3BhY2l0eToxJyAvPgo8cGF0aCBjbGFzcz0nYm9uZC05IGF0b20tOCBhdG9tLTEwJyBkPSdNIDY3LjEsNDAuOCBMIDY3LjcsMzYuNCcgc3R5bGU9J2ZpbGw6bm9uZTtmaWxsLXJ1bGU6ZXZlbm9kZDtzdHJva2U6IzNCNDE0MztzdHJva2Utd2lkdGg6MS4wcHg7c3Ryb2tlLWxpbmVjYXA6YnV0dDtzdHJva2UtbGluZWpvaW46bWl0ZXI7c3Ryb2tlLW9wYWNpdHk6MScgLz4KPHBhdGggY2xhc3M9J2JvbmQtOSBhdG9tLTggYXRvbS0xMCcgZD0nTSA2Ny43LDM2LjQgTCA2OC4zLDMyLjAnIHN0eWxlPSdmaWxsOm5vbmU7ZmlsbC1ydWxlOmV2ZW5vZGQ7c3Ryb2tlOiNFODQyMzU7c3Ryb2tlLXdpZHRoOjEuMHB4O3N0cm9rZS1saW5lY2FwOmJ1dHQ7c3Ryb2tlLWxpbmVqb2luOm1pdGVyO3N0cm9rZS1vcGFjaXR5OjEnIC8+CjxwYXRoIGNsYXNzPSdib25kLTkgYXRvbS04IGF0b20tMTAnIGQ9J00gNjQuNyw0MC40IEwgNjUuMywzNi4xJyBzdHlsZT0nZmlsbDpub25lO2ZpbGwtcnVsZTpldmVub2RkO3N0cm9rZTojM0I0MTQzO3N0cm9rZS13aWR0aDoxLjBweDtzdHJva2UtbGluZWNhcDpidXR0O3N0cm9rZS1saW5lam9pbjptaXRlcjtzdHJva2Utb3BhY2l0eToxJyAvPgo8cGF0aCBjbGFzcz0nYm9uZC05IGF0b20tOCBhdG9tLTEwJyBkPSdNIDY1LjMsMzYuMSBMIDY1LjksMzEuNycgc3R5bGU9J2ZpbGw6bm9uZTtmaWxsLXJ1bGU6ZXZlbm9kZDtzdHJva2U6I0U4NDIzNTtzdHJva2Utd2lkdGg6MS4wcHg7c3Ryb2tlLWxpbmVjYXA6YnV0dDtzdHJva2UtbGluZWpvaW46bWl0ZXI7c3Ryb2tlLW9wYWNpdHk6MScgLz4KPHRleHQgeD0nMTEuMicgeT0nNDIuNScgY2xhc3M9J2F0b20tMScgc3R5bGU9J2ZvbnQtc2l6ZTo2cHg7Zm9udC1zdHlsZTpub3JtYWw7Zm9udC13ZWlnaHQ6bm9ybWFsO2ZpbGwtb3BhY2l0eToxO3N0cm9rZTpub25lO2ZvbnQtZmFtaWx5OnNhbnMtc2VyaWY7dGV4dC1hbmNob3I6c3RhcnQ7ZmlsbDojNDI4NEY0JyA+TjwvdGV4dD4KPHRleHQgeD0nMjIuNCcgeT0nMzcuOScgY2xhc3M9J2F0b20tMycgc3R5bGU9J2ZvbnQtc2l6ZTo2cHg7Zm9udC1zdHlsZTpub3JtYWw7Zm9udC13ZWlnaHQ6bm9ybWFsO2ZpbGwtb3BhY2l0eToxO3N0cm9rZTpub25lO2ZvbnQtZmFtaWx5OnNhbnMtc2VyaWY7dGV4dC1hbmNob3I6c3RhcnQ7ZmlsbDojNDI4NEY0JyA+TjwvdGV4dD4KPHRleHQgeD0nMjIuNCcgeT0nMzIuNicgY2xhc3M9J2F0b20tMycgc3R5bGU9J2ZvbnQtc2l6ZTo2cHg7Zm9udC1zdHlsZTpub3JtYWw7Zm9udC13ZWlnaHQ6bm9ybWFsO2ZpbGwtb3BhY2l0eToxO3N0cm9rZTpub25lO2ZvbnQtZmFtaWx5OnNhbnMtc2VyaWY7dGV4dC1hbmNob3I6c3RhcnQ7ZmlsbDojNDI4NEY0JyA+SDwvdGV4dD4KPHRleHQgeD0nMzAuNCcgeT0nNTcuNCcgY2xhc3M9J2F0b20tNScgc3R5bGU9J2ZvbnQtc2l6ZTo2cHg7Zm9udC1zdHlsZTpub3JtYWw7Zm9udC13ZWlnaHQ6bm9ybWFsO2ZpbGwtb3BhY2l0eToxO3N0cm9rZTpub25lO2ZvbnQtZmFtaWx5OnNhbnMtc2VyaWY7dGV4dC1hbmNob3I6c3RhcnQ7ZmlsbDojRTg0MjM1JyA+TzwvdGV4dD4KPHRleHQgeD0nNzMuNycgeT0nNTEuMCcgY2xhc3M9J2F0b20tOScgc3R5bGU9J2ZvbnQtc2l6ZTo2cHg7Zm9udC1zdHlsZTpub3JtYWw7Zm9udC13ZWlnaHQ6bm9ybWFsO2ZpbGwtb3BhY2l0eToxO3N0cm9rZTpub25lO2ZvbnQtZmFtaWx5OnNhbnMtc2VyaWY7dGV4dC1hbmNob3I6c3RhcnQ7ZmlsbDojRTg0MjM1JyA+TzwvdGV4dD4KPHRleHQgeD0nNzcuOCcgeT0nNTEuMCcgY2xhc3M9J2F0b20tOScgc3R5bGU9J2ZvbnQtc2l6ZTo2cHg7Zm9udC1zdHlsZTpub3JtYWw7Zm9udC13ZWlnaHQ6bm9ybWFsO2ZpbGwtb3BhY2l0eToxO3N0cm9rZTpub25lO2ZvbnQtZmFtaWx5OnNhbnMtc2VyaWY7dGV4dC1hbmNob3I6c3RhcnQ7ZmlsbDojRTg0MjM1JyA+SDwvdGV4dD4KPHRleHQgeD0nNjUuOCcgeT0nMzEuNicgY2xhc3M9J2F0b20tMTAnIHN0eWxlPSdmb250LXNpemU6NnB4O2ZvbnQtc3R5bGU6bm9ybWFsO2ZvbnQtd2VpZ2h0Om5vcm1hbDtmaWxsLW9wYWNpdHk6MTtzdHJva2U6bm9uZTtmb250LWZhbWlseTpzYW5zLXNlcmlmO3RleHQtYW5jaG9yOnN0YXJ0O2ZpbGw6I0U4NDIzNScgPk88L3RleHQ+Cjwvc3ZnPgo=, Butterfly nut and production technique and stamping device for same, A kind of cold-heading processing method of wing screw, Butterfly nut processing die and process for processing butterfly nut by using same, Manufacturing process of building jacking nut, Method of metal forming and improved apparatus therefor, Process for cold stamping shaping steel thumb nut, Utilize the element coil material to forge the manufacture method of wing nut, Method for producing cold forging wing-shaped screw nut, A kind of wing nut and its production technology, decompressor, Processing technique of flat-head hexagon bolt for cold extrusion shaping cart, Multi-station cold heading forming technology of automobile door limiter, Cold heading forming manufacturing method for piston part of refrigeration compressor, A titanium alloy word counter nut forming die, A kind of big manufacturing process assembled than titanium alloy upset part, Cold-heading manufacturing method for radiator connector, Forming method for special-shaped cutting tooth with reinforcing ribs, A kind of cold upsetting die of car manufacturing automobile outer-hexagonal ball stud, Die forging for crank throw blank manufacture, Cold heading forming module for automobile connecting fork, Crowded mould of cold of strengthening rib shape pick is taken to dysmorphism, Method for manufacturing aluminum sheet circle for soft aluminum tube by aluminum rod, A kind of mould of the electrodeless clip of monaural, Entry into force of request for substantive examination, Deemed withdrawal of patent application after publication (patent law 2001), Invention patent application deemed withdrawn after publication.

Thus, the machine conveys motion from the driveshaft to the slide easily. Another embodiment of the present invention, please refer to Fig. | From a smartphone, to doors and windows, to cars and ships, how much ever compact or gigantic they are, they all need a fastner to hold them together. They are generally hex-shaped and are loosened and tightened with a wrench, while others are knurled.

of conf. Copyright 2015 - 2022 Deccan Chronicle. In the technical scheme of Chinese patent CN1317090C, the defective of this method is: owing to adopt cylindric wire rod, therefore, need to do middle the forging and slightly form the shape that oblate post is connected long column through spreading, could form stock through cutting off step again, again through the squeezing shaping step, the groove that is swaged into chamfer shape is inwardly pushed in both sides, oblate post center, and the groove periphery is outwards forged long shaping, ability shape coarse-blank, afterwards, do through hole again, final step is the alar part moulding, need long column be forged into one group of mould upwards to roll over perk and gradually wide flat butterfly wing, and this method fabrication schedule is loaded down with trivial details consuming time, production efficiency still can't improve, and manufacture method through six steps, needs different processing mechanical apparatus to cooperate at cylindric wire rod, causes the production line lengthening and increases cost. If you look around, almost every big and small object around us is held together with screws, nuts and bolts. Its ideal for minor forgings like hooks, blanks for knives, chisels, particles needing repetitive heating, axes, and blanks for propellers. Sunday, Jul 31, 2022 | Last Update : 02:13 AM IST. stream MW Components produces nuts and other fasteners for a variety of industries and applications. Some examples of these may include, Vibra-Tite and other anti-loosening finishes.

B2-20120091-4. 5 0 obj

Ladder logic programming is done in control logix PLC from M/s Rockwell after building logic sequence, control loops and interlocks of coal leaching process.

Ladder logic programming is done in control logix PLC from M/s Rockwell after building logic sequence, control loops and interlocks of coal leaching process. View Full List of Available Certifications. | - The first category is the horizontal forging machines that use horizontal movements while forging metals. /Type /Stream >> 4 0 obj

Their work is to enhance production during the forging process. Alibaba.com Site: International - Espaol - Portugus - Deutsch - Franais - Italiano - - P - - - - - Trk - Nederlands - ting Vit - Indonesian - , AliExpress By the method, the processing procedures of the wing nut cap can be shortened and simplified; the production is quick; the yield is sharply increased; the waste materials are few; the cost is reduced; and the industrial competitiveness is greatly improved. Terms of Use | Showroom 5 is another wing nut of the present invention top cross-sectional view in process of production. Companies generally operate with a run-to-failure or planned maintenance approach.

Their work is to enhance production during the forging process. Alibaba.com Site: International - Espaol - Portugus - Deutsch - Franais - Italiano - - P - - - - - Trk - Nederlands - ting Vit - Indonesian - , AliExpress By the method, the processing procedures of the wing nut cap can be shortened and simplified; the production is quick; the yield is sharply increased; the waste materials are few; the cost is reduced; and the industrial competitiveness is greatly improved. Terms of Use | Showroom 5 is another wing nut of the present invention top cross-sectional view in process of production. Companies generally operate with a run-to-failure or planned maintenance approach. Explore our capabilities and request a quote for your part.

Hex Bolt And Screws Making Machine Hex Head Self Tapping Screw Cold Heading Machine For Making Bolt Screws, Hex Nut Factory Supply Hex Nut Making Machine Hot Sale, Hex Nut M6-M10 Hex Nut Making Machine/ Automatic Nut Forging Machine Factory Price, Hex Factory Directly Sale Hex Head Tail Drilling Screw Making Machine, Hex Nut Manufacturer High Quality Hex Nut Thread Making Machine Manufacturer, Fully automatic drilling and tapping machine Thread processing equipment Nut automatic tapping machine, Taiwan High Speed Hex Nut Tapping Machine Manufacturer Price Flange Nut Tapping Machine, Hex Bolt Making Machine Line,High Speed Automatic Hex Bolt Nut Forming Machine,Factory Price Bolt Trimming Machine, 24 Hours Working M21 Pipe Lock Nut Hex Nut Tapping Machine, Multi-station Hex Nut Flange Bolt Nut Cold Bolts And Nuts Making Machine, Hex Nut Four Spindle Double Vibration Type Nut Fasteners Internal Tooth Tapping Machine Tapping Equipment, Automatic Feeding M5 Pressing Rivet Nut Thin Hex Nut Tapping Machine, Electronic Counting M23 Thin Hex Nut Bushing Tapping Machine, Automatic M19 Bushing Thin Hex Nut Tapping Machine, High Capacity M11 Hex Nut Square Nut Tapping Machine, Automatic Feeding M5 Nylon Lock Nut Hex Nut Tapping Machine, Stainless steel thin wall fast jam 50mm hex nut manufacturing process, Manufacturing Process Cheapest Wholesale Titanium Hex Nuts, Factory Direct Sales Din 934 Hex Nut Zinc Plated For Manufacturing Process, double hex nut Israeli sleeve anchor, 1/4*102 Israeli sleeve anchor factory, Automatic Lathe Processing Riveted Studs Nuts Standoff, Manufacture custom Skate Wheel Screw Nail Bolt Nut Tool Skate Wheel Bolt Set Inline Replacement Skate Wheel Axles, Stainless steel extended standoff hex nut from manufacturer, china manufacturer heavy truck m22 hex wheel nut, Factory manufacture brass round steel long hex coupling nut, Non-standard nut Professional Manufacturer Directly Supply Brass Nut Screw For Industrial Production, Sales Service M46 Nut Cashew Nut Processing Line M46 Nut Manufacturer, 2022 China manufacture hot sale black dacromet xylan ZP ASTM ISO GB DIN/customized steel structure hex nuts for building, Stainless steel DIN929 DIN928 hex weld nuts/ square weld nut, Manufacturers process custom aluminum profile accessories aluminum alloy gaskets, 100% Natural Cashew-Nut Raw Material Special Healthy Safe WW320-WW240-WW350 Cashew Nut By Vietnam Manufacturers, Din934 W320 Manufacturer Direct Sale Customizable Professional other nuts processing machines and betel Nut, Customizable offer customize vibratory hex small nut bowl for spring, China Fastener Manufacturer M8 M10 Ss304 Butterfly Nuts Precision Casting Din315 Stainless Steel Wing Nut, Hex Nut Standard Hexagon Plastic Automotive Flame Nylon Class Screw Material Origin Shape Fit GUA Working Size General Place, China's nuts and bolts manufacturers Processing quality bolts nuts and screws. PIb_j'y E~8=Z!

kn= Even with a planned maintenance schedule, however, The nut manufacturing machine operates almost continuously throughout the day and, consequently, requires frequent maintenance, the duration of which depends on the type of fault. Nut fasteners are produced by machines working around the clock. 1688.com Semantic Scholar is a free, AI-powered research tool for scientific literature, based at the Allen Institute for AI. All rights reserved. All rights reserved. Described punch forming method, with sheet metal through punching press tortuous with cut off moulding, in manufacture process, can produce sharp keen burr, easy incised wound finger, and can produce more scrap metal causes cost of idleness, deficiency in economic performance. Intellectual Property Protection 3 is a wing nut of the present invention schematic rear view in process of production; Fig. The third type is the forging rolls that are ideal for rolling units and forging machines. In addition to standard engineering and manufacturing services, we offer various additional services.

Hex Bolt And Screws Making Machine Hex Head Self Tapping Screw Cold Heading Machine For Making Bolt Screws, Hex Nut Factory Supply Hex Nut Making Machine Hot Sale, Hex Nut M6-M10 Hex Nut Making Machine/ Automatic Nut Forging Machine Factory Price, Hex Factory Directly Sale Hex Head Tail Drilling Screw Making Machine, Hex Nut Manufacturer High Quality Hex Nut Thread Making Machine Manufacturer, Fully automatic drilling and tapping machine Thread processing equipment Nut automatic tapping machine, Taiwan High Speed Hex Nut Tapping Machine Manufacturer Price Flange Nut Tapping Machine, Hex Bolt Making Machine Line,High Speed Automatic Hex Bolt Nut Forming Machine,Factory Price Bolt Trimming Machine, 24 Hours Working M21 Pipe Lock Nut Hex Nut Tapping Machine, Multi-station Hex Nut Flange Bolt Nut Cold Bolts And Nuts Making Machine, Hex Nut Four Spindle Double Vibration Type Nut Fasteners Internal Tooth Tapping Machine Tapping Equipment, Automatic Feeding M5 Pressing Rivet Nut Thin Hex Nut Tapping Machine, Electronic Counting M23 Thin Hex Nut Bushing Tapping Machine, Automatic M19 Bushing Thin Hex Nut Tapping Machine, High Capacity M11 Hex Nut Square Nut Tapping Machine, Automatic Feeding M5 Nylon Lock Nut Hex Nut Tapping Machine, Stainless steel thin wall fast jam 50mm hex nut manufacturing process, Manufacturing Process Cheapest Wholesale Titanium Hex Nuts, Factory Direct Sales Din 934 Hex Nut Zinc Plated For Manufacturing Process, double hex nut Israeli sleeve anchor, 1/4*102 Israeli sleeve anchor factory, Automatic Lathe Processing Riveted Studs Nuts Standoff, Manufacture custom Skate Wheel Screw Nail Bolt Nut Tool Skate Wheel Bolt Set Inline Replacement Skate Wheel Axles, Stainless steel extended standoff hex nut from manufacturer, china manufacturer heavy truck m22 hex wheel nut, Factory manufacture brass round steel long hex coupling nut, Non-standard nut Professional Manufacturer Directly Supply Brass Nut Screw For Industrial Production, Sales Service M46 Nut Cashew Nut Processing Line M46 Nut Manufacturer, 2022 China manufacture hot sale black dacromet xylan ZP ASTM ISO GB DIN/customized steel structure hex nuts for building, Stainless steel DIN929 DIN928 hex weld nuts/ square weld nut, Manufacturers process custom aluminum profile accessories aluminum alloy gaskets, 100% Natural Cashew-Nut Raw Material Special Healthy Safe WW320-WW240-WW350 Cashew Nut By Vietnam Manufacturers, Din934 W320 Manufacturer Direct Sale Customizable Professional other nuts processing machines and betel Nut, Customizable offer customize vibratory hex small nut bowl for spring, China Fastener Manufacturer M8 M10 Ss304 Butterfly Nuts Precision Casting Din315 Stainless Steel Wing Nut, Hex Nut Standard Hexagon Plastic Automotive Flame Nylon Class Screw Material Origin Shape Fit GUA Working Size General Place, China's nuts and bolts manufacturers Processing quality bolts nuts and screws. PIb_j'y E~8=Z!

kn= Even with a planned maintenance schedule, however, The nut manufacturing machine operates almost continuously throughout the day and, consequently, requires frequent maintenance, the duration of which depends on the type of fault. Nut fasteners are produced by machines working around the clock. 1688.com Semantic Scholar is a free, AI-powered research tool for scientific literature, based at the Allen Institute for AI. All rights reserved. All rights reserved. Described punch forming method, with sheet metal through punching press tortuous with cut off moulding, in manufacture process, can produce sharp keen burr, easy incised wound finger, and can produce more scrap metal causes cost of idleness, deficiency in economic performance. Intellectual Property Protection 3 is a wing nut of the present invention schematic rear view in process of production; Fig. The third type is the forging rolls that are ideal for rolling units and forging machines. In addition to standard engineering and manufacturing services, we offer various additional services. This hex nut manufacturing process is tailored for the finish and pre-forming forging of bar stock. Condition Monitoring to Enable Predictive Maintenance on a Six-Die Nut Manufacturing Machine through Force Data Analysis, Application of vibration analysis using time-frequency analysis to detect and predict mechanical failure during the nut manufacturing process, Instrumentation and automation system at coal leaching pilot plant, Programmable Automation Controller Mechatronic Experiment, Competitiveness Comparative Research on Jiaozuo Service Industry Based on Synchronic and Diachronic Data, Corrosion Protection, Basic corrosion theory and protection methods, Automation of Coal Handling Plant, Pro. 4 and shown in Figure 5, be between basic blank (10) step and alar part shaping (20) step, add alar part blank (20A) step, this alar part blank (20A) step utilizes little fin radian module of repairing that the double fins 22 of thick embryo 2 is carried out differential of the arc forging and pressing, make fin 22 through alar part blank (20A) and alar part shaping (20) step by the gradual one-tenth of the trace butterfly wing, make the exquisite more perfection in circular arc limit 221 of the butterfly wing. Thus choose according to your preference as they differ in production rates. The method comprises the following steps of: cutting a round bar-shaped metal linear material into sections serving as blanks; directly forging and stamping the blanks into crude blanks with nut cap sections through a basic embryo molding step, wherein bent wing sheets are connected to the two sides of the crude blanks; forging and stamping the two wing sheets into butterfly wings with arc sides through a wing shaping step; forging and stamping the nut cap sections into cropping tapers through a nut edge forming step, wherein a positioning groove is concavely formed in the centers on the upper side and the lower side respectively; and forming a semi-finished product with a wing nut cap shape in a cold forging way, and forming a complete wing nut cap through ordinary through hole and tapping steps. | Known simple and easy sealed design, mostly cooperate nut directly to screw togather by relative screw thread with bolt, reach sealed assembling, and general nut need be used instrument (spanner) operation usually, could lock or dismantle, for this reason, thereby a kind of wing nut that has two butterfly wings can easy operation is early arranged, but existing wing nut manufacture method is nothing more than being divided into cast-forming method and punch forming method; Wherein: Described cast-forming method, the molten metal liquation is injected the sand mo(u)ld casting, but this forming method, need earlier through the founding molding, with metallic high temperature liquefaction, through the program of injection molding and die sinking, manufacture process is quite loaded down with trivial details again, and the finished product after the moulding forms most pores, causes that rough surface is unsmooth, texture difference and easy fracture. (Adobe) After spending hours in a furnace to soften it enough to be worked, the wire rods go in a bath of sulphuric acid to remove any rust particles on it, which is then followed by various other procedures to mould it into the desired form. CAD files for stock and standard nuts are available for download in MW OnDemand. View 2 excerpts, cites methods and background, Service industry plays a more and more important role in economic development, it had become an important symbol for the enhancement of one region competitiveness.

- Our closeout inventory is in-stock, ready to ship, and available while quantities last. %PDF-1.7 1. a wing nut manufacture method is characterized in that, with the round bar shape metal wire rod section of cutting into as stock, via the following step: Basic blank step is utilized wing nut basic styling module directly stock to be forged into to have the nut section and both sides are connected the thick embryo of blank body that folded over tab is arranged; Alar part shaping step utilizes fin radian trimming module that the butterfly wing that becomes to have the circular arc limit is rebuild in the two fins forging and pressing of thick embryo; The marginal ridge forming step utilizes the nut Shaping Module that the forging and pressing of the nut section of thick embryo are shaped to the crop taper and the upper and lower sides center respectively is concaved with locating slot, finishes the semi-finished product of a wing nut outward appearance; After the above-mentioned procedure of processing, be that central point gives through hole, tapping forms a wing nut with the locating slot of this nut section. Lazada, Browse Alphabetically: Nuts are generally made from stainless steel in standard sizes ranging from 0-80 to 3/4-10. If you continue to use our site, you agree to the updated Policies. MW Components' Hyperco brand is a Competition Partner and supplier to the NASCAR Cup Series.

endobj

33010002000092 Click on Deccan Chronicle Technology and Science for the latest news and reviews. The basic blank 20-alar part of 10-shaping 20A-alar part blank 30-marginal ridge is shaped, The thick embryo of 40-through hole 50-tapping 1-stock 2-, 21-nut section 211-locating slot 22-fin 221-circular arc limit. /Filter /FlateDecode The present invention relates to a kind of wing nut manufacture method, especially a kind of wing nut manufacture method of simplifying procedure that shortens.

Further, can also be between basic blank and alar part shaping step, add an alar part blank step, utilize little fin radian module of repairing that two fins of thick embryo are carried out differential of the arc forging and pressing, just the gradual butterfly wing of rebuilding into is adopted in the differential of the arc forging and pressing in advance of described two fins, make the radian on butterfly wing circular arc limit exquisite more perfect. Thus, visit Alibaba.com and choose your liking metal forging machinery at a wholesale price. We have over a hundred API BSL-1 certified stud and nut designs in-stock and ready to ship. The functional element is linked to a crank gear system where a camshaft mechanism activates the auxiliary parts.

According to as can be known above-mentioned, wing nut manufacture method of the present invention is compared with prior art, has plurality of advantages really, and details are as follows: 1. wing nut manufacture method of the present invention, by simple and easy steps such as basic blank, alar part shaping, marginal ridge shapings, finish the manufacturing processing of wing nut, save many steps with respect to prior art, reach the simplification process, do not need too much processing mechanical apparatus, save equipment purchasing cost and maintenance cost relatively, and improve throughput rate and efficient, be good innovation and creation in fact. - User Information Legal Enquiry Guide, 1999-2022 Alibaba.com.

We have updated our Privacy and Cookie Policy. Unpredicted. We produce custom injection molded parts, including micro molded components and those that require insert molding and overmolding. Nuts are female fasteners with a threaded hole and are used to secure a stud or bolt. Shown in 2 and 3, the step of the embodiment of the invention includes in conjunction with the accompanying drawings: Basic blank (10) step is utilized wing nut basic styling module directly stock 1 to be forged into to have nut section 21 and both sides are connected the thick embryo 2 of blank body that folded over tab 22 is arranged, and is moved in alar part shaping (20) step by an anchor clamps gripping; Alar part shaping (20) step utilizes fin radian trimming module that the butterfly wing that becomes to have circular arc limit 221 is rebuild in two fins, 22 forging and pressing of thick embryo 2, is moved in marginal ridge shaping (30) step by an anchor clamps gripping; Marginal ridge (30) step that is shaped utilizes the nut Shaping Module that the nut section 21 of thick embryo 2 is shaped to the crop taper and the upper and lower sides center respectively is arranged with locating slot 211, thereby finishes the semi-finished product of wing nut outward appearance, is shifted out by an anchor clamps gripping; After gripping processing by above-mentioned three step letters, the semi-finished product of this wing nut outward appearance are sent in the interior locating module of through hole (40) step at once and are located, locating slot 211 with nut section 21 is a central point, it is die-cut to carry out through hole, make it have a through hole 23, and take tapping (50) step again at these through hole 23 places, thereby become the complete wing nut with internal thread, it can lock with screw threaded and combine; In view of the above, adopt the metal wire rod section of cutting into, forge into the continuous automatic operation of wing nut one by one, reach shortening and simplify procedure, produce purpose rapid, that output is increased sharply, can promote economic benefit, strengthen industrial competitiveness more significantly as stock 1. 8 0 obj There are different types of forging machines that serve different purposes. endobj For solving the defective of above-mentioned prior art, the inventor is engaged in the experience of screw, nut manufacturing for many years with accumulation, dive meticulously and grind, test again and again, and adhering to the invention spirit of working with perseverance, finally develop a kind of procedure simplification, rapid, waste material is low, and the wing nut manufacture method that can reduce cost.

Watch the video below to see the entire process of manufacturing these fastners. on control communication and power Engineerin, Programmable Logic Controllers and Industrial Automation an Introduction.A text book by Madhuchanda Mitra and Samarjit Sen Gupta, Module 7, Screw threads and Gear Manufacturing Methods, Lesson 31,Production of screw threads by Machining, Langill,2006,Corrosion Protection, Basic corrosion theory and protection methods, An Anecdotal History of the Galvanizing Industry (Commissioned by the American galvanizers Associatio, High Tensile Nuts And Bolts, prepared by Small Industries Service Institute Industrial Estate, Corrosion costs money, The Columbus battle institute estimates that corrosion costs Americans more than $ 220 billion annually, about 4.3% of the gross natural product [1].Now a days due to increase of pollution, the rate of corrosion is also increasing day-by-day mainly in India, so, to save the steel structures, galvanizing is the best and the simplest solution. The paper compares the pros and cons of using a PAC versus Programmable Logic Controller (PLC) or Field Programmable Gate Array (FPGA) systems, and introduces the flowchart based programming environment used in PACs. : At first please refer to shown in Figure 1, a kind of wing nut manufacture method provided by the invention, with the metal wire rod section of cutting into of round bar shape as stock 1, the cold-forge forming machinery that cooperates the wing nut special use, directly procedure is simplified in the shortening of forming through basic blank (10), alar part shaping (20) and marginal ridge shaping steps such as (30), finish the semi-finished product of wing nut outward appearance in the cold forging mode, pass through general through hole (40), the tapping rapid moulding of step continuous and automatic such as (50) again, obtain complete wing nut finished product. These nuts and bolts are made from whats called steel wire rods. Below are examples of commonly requested finishes we can add to this product. | Country Search | Suppliers hex nut manufacturing process is very strong and works efficiently with a high production rate, improving your earnings and making your business more productive. Secondly is the vertical forging machine, where the tool moves vertically. While the majority of the nuts we produce are manufactured using standard sizes and materials, we offer many specialty materials, finishes, certifications, sizing options, and related fabrication processes.