3. Cheap chinese K40 laser upgrades, including 60x30cm working area, MKS or SKR controllerboard (smoothieware or marlin, not yet decided.) The Y-1200 has a cutting area of 1200 x 600mm and the main chassis has a external size of 1620 x 955 x 450mm. Yaskawa servo motors, RF 100w laser cutter build, aluminium extrusion. The software create a vector file and send it to the controller which guide the laser beam by means of the stepper motors to traverse a particular path onto the material surface. Share it with us!  This is my take on the Acro Laser system made from mostly salvaged, scrap, or leftover parts.

This is my take on the Acro Laser system made from mostly salvaged, scrap, or leftover parts.

Worse off, the ones with cheaper prices attached to them produce low megawatts that can barely cut a piece of paper, much less a piece of wood, or harder materials like metal.

Start building from scratch your different mini laser CNC laser cutter/engraver following the guides from this DIY tutorial. Machine body and worktable1. Laser source and laser delivery systemThe laser source and laser delivery system includes Laser power supply, laser tube, reflective mirror, lens. Collaborate on our forums and be sure to visit the Part Store for all your Maker needs. Reflective mirror: Moleynium lens (named metal mirror,orsilver mirror) and Silicone based mirror (gold mirror). Most of my works are related to Solar Energy and Arduino. After waiting for a long time, GearBest given me this 5500mW Laser Engraver for review. You might not even be interested in learning how to create a laser cutter but just want the knowledge.

It will be see-through with lights and screens eveywhere. The y-motors run fine (not hot), just the x-motor (within 2 minutes of use). Ruida controller. Then adjust the laser head position to align it on to the material by pressing left-right or forward-backward button in the software.

Light, psu and a bit more :), The Smart Laser Mini is an open source such as use Raspberry pi. After expanding a Shapeoko 2 with the rails and motors left over, make yourself a laser engraver.

This project was created to help most artisans create their own high-power laser cutter at an affordable rate. Depending on the laser intensity and speed of traverse, quality of engraving changes.If the Laser beam is much powerful then it can cut thick materials like hard wood and acrylic also.

I Use Mach3 on my C-Beam XL to Mill.

Also we used V-slot, Progetto di un laser CO2 da 50w I haven't got the steppers working though. The main purpose is to cut EVA foam. Modifying the K40 laser cuter stock gantry in favor of OpenBuilds superior and smoother movement.

Attached you will find a part list with quantity and link where to buy. on Introduction. It is a great resource tutorial for amateur industrial students. Wannabuild a laser engraver? This is my build for an ACRO system with a custom z-axis for changing z height for focusing or for adjusting depth when making multiple passes when cutting. By now, if you are a lover of craft or an avid lover of woodwork and material engraving, you would have figured out how expensive it is to get a quality and durable laser cutter machine. Of course this assumes you bought an Eleksmaker A3 or plan to. 300x300 belt drive laser etching/cutting platform. Load an image you want to engrave /cut.

wooden parts of the enclosure can be removed easily It runs on two microcontrollers, an Arduino with GRBL and a raspberry pi with a touchscreen to control the parts of a laser cutter. Hi,Thanks for the information.

low cost 2 axis cnc laser, really portable and easily expandable, DIY Lasercutter: Budget orientated, medium sized (60-100w), safety first, based on Lasersaur software toolchain. Hi, I'm Allison! Gladly taking advices from others. First a design pattern is loaded to the Controller Software. on Introduction. 3.8 W laser add-on for C-Beam machine.

Large 10x6 vacuum table made from steel tubing and 1/4 inch steel plate.

2. Then set the different parameters and hit the play button.

2. Starting the next Laser build, Plan to complete within 60 days. This is one of those cheap projects to carry out if you build a CNC laser cutter/engraver.

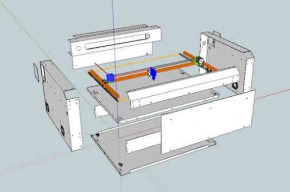

LASER" stands for "Light Amplification by Stimulated Emission of Radiation". Carve Mode : Can be i ) one-way (left to right), ii ) Z for bi-directional (left-right-left etc.) Uses standard off the shelf components in almost 90% of the build with the exception of the axes motor and wheel mounts which need to be 3D printed. Hence the overheating and "jump" issues. Apart from Electronics I love 3D printing, Woodworking and to make crafts from used , https://www.youtube.com/playlist?list=PL-rD3JlrFRdiOLWFIR_4tXwQDcAgvSG18. I have pulled the Model apart in Sketchup, isolated the Plates and generated the G-Code to cut/Mill the plates. How i construct and create my DIY Co2 Laser cutter and engraving mashine. This is a laser cutter built with intent to use arduino as controller for a co2 cutting laser. I strongly believe this is the fastest and most creative way of getting ideas out of the mind, and onto the floor. A co2 laser build that is heavily inspired and based quite a bit off Pedro Fernandez' 50w co2 laser build. Laser Module : Which emits high intensity light beam. Follow all the processes and map out designs and measurements to achieve a great result.

1 year ago. Subscribe for more interesting DIY projects.

Note : In the second page, you have to only change the PPM and Feed Rate.No need to change the other parameters if you are not an expert. They can also cut small diameter holes with complex detailing and good edge quality; they are also really economical to use. Follow the [ Video ] to assemble the Laser Engraving Machine. Total cost of the machine is ~ $1,400 USD. Motor: Stepper motororServo motor, stepper motor is popular for low power laser cutting and engraving machine.

The focal length commonly like 1.5(38.1mm), 2(50.8mm), 2.5(63.5mm), 3(76.3mm). I then noted the x-axis motor gets hot very quickly, so I replaced it. Aluminium frames / Sticks (2 small, 3 large), 6. Now follow the above picture to connect all the cables to the Controller/Driver Board.

In the expo projects during the second year of engineering students.

( 412x455mm) Thanks for stopping by, if this DIY laser cutter article has been helpful, do well to share it across your social media accounts.

After successful updation a green tick mark will be appeared.

It can serve as a pretty fancy piece of torchlight to light candles, but be careful as they are really powerful and burn really hard. Laser CNC made with mostly Openbuilds and amazon sourced components. And build your very own laser cutter for just as much as $400.

One of the best deals ever! This build is for a testing rig to use while testing out different controller boards and CAM software for milling and routing. Large 6 x 10 foot laser table build. Have a few problems with your old laser cutter? HelloI have a 15pin laser with a 4pin terminal.I do not understand the connection method of "benbox" base.I want to connect another 12v7A power supply for the laser module at the same time. Discrete : Stops the laser on each pixel based on the time value, it is slower but more accurate. Question So I will guide how to install the Benbox software and use it. hello,just a word of caution cardboard BURNS and real FAST when fed by a laser,I use a piece of 3/4 inch Russian Birch plywood with mini heatsinks spaced about 2 inches in both directions as a base platethe laser is focused to the top of the heatsinks and yes stuff does catch fire so you need a spray bottle filled with water very close by by the way I am using a 2.5 watt laser and laser GBRL.please be careful also for smoke I have a computer fan feeding a old vacuum cleaner hose directly to the chimely.

Yes another K40 Franken machine dedicated for round objects,,. Hopefully this will be a quick guide to one way that you can add a laser to an existing CNC router.

Going to try and use all or most off the shelf parts. Honeycomb worktable is very popular for soft material cutting such as leather, garment, paper, rubber and etc. Select the board to " NANO(328p) / LX- Nano. I just have one question: The x-axis "jumps" about an inch or so in the middle of etching, making it impossible to finish any project. So this is my custom 40W build. (I shall add the link if possible under this)https://www.youtube.com/playlist?list=PL-rD3JlrFRdiOLWFIR_4tXwQDcAgvSG18, Question Question

Easy to assemble type of desktop laser cutter and engraver. Cree.

This.  Go to the menu in the software and press connect. I have completed some custom build 3d printers (i3 and delta style) and a cnc mill based on v-slot and c-beam. Then slowly rotate the focusing ring to focus the laser beam falling on the engraving surface. 3 years ago, sir video is not available.please post it again. II. Build Summary updated after parts list completed, A K40 to ACRO Co2 laser cutter build.

Go to the menu in the software and press connect. I have completed some custom build 3d printers (i3 and delta style) and a cnc mill based on v-slot and c-beam. Then slowly rotate the focusing ring to focus the laser beam falling on the engraving surface. 3 years ago, sir video is not available.please post it again. II. Build Summary updated after parts list completed, A K40 to ACRO Co2 laser cutter build.

Parts Box : 6 small acrylic frames,Screws, timing belt, pulleys,washers and spacers. Build of a small laser engraver using V-slot profiles and 3d printed parts. Building of a big open frame laser engraver. It is a really fun project you should try out, but remember to be careful as laser beams, if missed, are highly dangerous to not only us but both our loved ones and the general public, which is why this video also explains how to create and use the laser beam for projects carefully.  Hi everyone, im new to the world of lasercutters but i have been granted access for a Trotec laser for a while with old firmware and only compability trought Windows XP. Electronics setup usually take an arduino uno, withgrbl shield. he wheel roller linear guide commonly divide into outer wheel roller linear guide and inner wheel roller linear guide.

Hi everyone, im new to the world of lasercutters but i have been granted access for a Trotec laser for a while with old firmware and only compability trought Windows XP. Electronics setup usually take an arduino uno, withgrbl shield. he wheel roller linear guide commonly divide into outer wheel roller linear guide and inner wheel roller linear guide.

Hi..am mell frm Malaysia. 50 cm X 50 cm but I get 40cm x 35 cm as a real workread, Light weight portable Laser Engraver (6.5lbs - 12lbs). The laser mount has adjustable knob to manually rise or down the laser for focusing purpose. Struttura realizzata con profili T-slot 20x20 e 20x40, Rotary attachment to engrave cylindrical objects on laser machines. Note down the COM PORT No. used the existing extraction of my glass bead burners.

::  this laser needs to live outside. The aluminum frames are assembled and joined at the right parts, and it makes you a mini 3D printer centered on the aluminum frames.

this laser needs to live outside. The aluminum frames are assembled and joined at the right parts, and it makes you a mini 3D printer centered on the aluminum frames.

Well I built a C-Beam XL around a year ago, I am still learning things as I make stuff with it, it has been quite a wonderful learning experience. Laser cutters are part of a cutting technology that uses laser beams to vaporize materials, resulting in a cutting edge. I have used Sketchucam to generate the G-Code.

If you are innovative at heart and have some amazing ideas for uses, this laser engraveing machine might be just the tool that will send you into a whole new realm of DIY platform.Still now I am new to Laser engraving, and learning new techniques from different forum and articles.If I will find new information, I will update here. Was a very fun project to assemble. I have built my own engraver by myself. Please not the BOM only covers parts from the OpenBuilds part store. By following the way of Robert Hummel, I drew a version of its exellent Laser V to use NEMA17 and easily printable parts. Since im still a student i have limited resources, so i will try too use scrap parts as much as possible. I was making this project today when I noticed the laser light did not penetrate on certain portions of the Douglas Fir wood. 6. The problem with this highly helpful machine is the fact that it is expensive to get, you do not have to worry about going past your budget to acquire a laser cutter these days as they can now be easily made from scratch at home, and I have been able to compile 14 of the best DIY laser cutter projects that will teach you how to make yours. Unlike traditional mechanical cutting techniques, laser cutters reduce the contamination of workpieces. Large format laser build for Student use at my school as well as some personal use. If tried adjusting the beam of the light, sanding the unburnt section and slowing down the speed yet same result. Machine body: Sheet metal machine body and aluminum profile frame machine body.Sheet metal machine body very popular in the market, in the future aluminum profile frame machine body will be existing in the market more and more, which can be packed in small size box for shipping for saving shipping cost from China to other countries, and more suitable more laser cutterorlaser engraver DIY purpose2. 2. The focal length 2(50.8mm) and 2.5(63.5mm) is most popular in the laser market. You can make as many mini lasers for businesses as quickly as possible without struggling. A build which is based on a metal frame and aluminium plate which I salvaged from a skip.

In this Instructable, I want to share my experience on assembling the Laser Engraver, about the using of laser engraver/cutter and what you can do with it . The design was borrowed from another's blog and customized to fit materials on-hand. 1.

The first months have mainly been about designing and building an XY-table on which later all the electronic components will be added and the laser. Now I have gained enough confidence and knowhow to Mill the required Plates to build an Acro Laser System using the Acro Laser Sketchup Model. Save my name, email, and website in this browser for the next time I comment. Do you have an old DVD and you are thinking of what fun new experimental project to make use of it or parts of it to create, the mini CNC laser cutter/engraver consisting of DVD drivers is just the perfect project for you. It is a creative start to finish project for all beginners.

Y-1200 Build Z-Axis for OpenBuilds ACRO system.

This was my first engraver you can see in action here: Lot of projects could be foundgoogling for laser engraver from dvd, https://www.instructables.com/id/Pocket-laser-engraver/, https://www.instructables.com/id/DVD-to-Laser-Engraver/, https://davidegironi.blogspot.it/2014/07/38mm-x-38mm-laser-engraver-build-using.html#.WLYOp982vct. The OpenBuilds Team is dedicated helping you to Dream it - Build it - Share it! Vslot rail system at work again, laser cutter/engraver rotary device for cylindrical objects . 20 DIY Rock Tumbler Projects: How To Make A Rock Tumbler, 20 DIY Table Saw Workbench Projects: Do It Yourself Easily, 24 DIY Router Table Projects: How To Build A Router Table, 12 DIY Sawmill Plans: How To Build A Sawmill Like A Pro, 24 DIY Spot Welder Projects: How To Make A Pro Spot Welder, 20 DIY Log Splitter Projects: Do It Yourself Easily, 15 DIY Table Saw Projects: How To Make A Homemade Table Saw, 20 DIY Wood Lathe Plans: How To Build A Wood Lathe, 23 DIY Micro Camper Plans You Can Build Easily, 25 Brilliant and Easy to Build DIY Computer Desks, 23 DIY Computer Case - How To Build A Computer Case, 15 DIY Target Stand Projects - How To Build A Target Stand For Shooting, 25 DIY Shower Wall Panels Plans You Can DIY Easily, 19 DIY Slide Projects - How To Build A Play Slide, Diy Game & Recreation Room Furniture Projects, 14 DIY Laser Cutter Projects: How To Build A Laser Cutter, 25 DIY Wood Cross Designs: How To Make A Wood Cross, 14 DIY Slant Board Projects: How To Build A Slant Board. Low cost Laser Engraver build using all off-the-shelf components. This is a long term experiment, so the build status will remain as "Build in progress" until the experiment has been completed.

Laser power supply: famous brand such as Hongyuan brand, 60w (T60), 80w (T80), 100w (W120), T150 (150w, for 130w and 150w laser tube). First plug in the USB cable and 12V power adaptor. Some of these supplies include; a Capacitor, a Resistor, Arduino, Arduino PCB, 3D printers, 250mW laser, motor drive, transistor, magnet, 12V power, amongst a host of other materials. https://showsyouhow.blogspot.it/2007/12/diy-dvd-burner-laser-pointer-proper-way_18.html. PPM should be 320 for both X and Y to get the good result.

The beam is focused down to a point as small as one-thousandth of an inch and can burn, melt, or even vaporize the material it hits.

Linear motion system1. Sheet metal machine body very popular in the market, in the future aluminum profile frame machine body will be existing in the market more and more, which can be packed in small size box for shipping for saving shipping cost from China to other countries, and more suitable more laser cutterorlaser engraver DIY purpose.

First Turn On the laser switch on the Driver Board.

1. I could never really justify the expense.Now the prices have come down to the point where theyre now affordable for DIY enthusiasts. Awaiting parts delivery to start build.

https://www.instructables.com/id/3D-printed-Laser-Engraver/, https://www.instructables.com/id/Arduino-Laser-Engraver-Wood-Design/, https://mircoslepko.blogspot.it/2015/03/1-watt-cnc-laser-cutting-engraving.html(ITA), ALWAYS WEAR SAFETY GLASSES WHEN EXPERIMENTING WITH LASER, https://mircoslepko.blogspot.it/2015/03/1-watt-cnc-laser-cutting-engraving.html, AliExpress (full engraver, modules, spare parts). Note : This Instructable is not sponsored, Gearbest sent me this Laser Engraver to review, they did not paid me.This is not to promote the product, rather it is intended to help others and to share my experience on Laser Engraving. 3 years ago

It is in the early stages, planning is complete, parts are ordered. A re-imagining of Dollarz81's XXL Tank in Laser form, 4foot by 2 foot, 10W El-Cheapo blue laser. Designed to give the most function using the very least number of parts at the lowest price. Leetro MPC6515, MPC6535, MPC6585, Leetro 8530s (new), Control panel (operating panel,LED panel)English software: RDworks V8 (RuiDa), Lasercut2017 (Leetro).

The goal of Project Laser Cutter is to build a laser cutter, which is safe and can be used within the school.

2. Anything, can u direct me on my email muzs82@gmail.com. Synrad 50w CO2 laser. 2 years ago, Thank you for your very informative feature on the Benbox. You can now easily create your own CO2 laser cutter using the combination of a 'V & T' spotted aluminum profile 3d printed parts. That is why I have started this build of co2 laser machine. I think it will be very useful for other DIY hobbyist to upscale their work. 123 bar cut into 2 x 610 mm, 1 x 790 mm and 1 x 1105 mm parts. Can this cut hotfoil paper? The laser engraving machine has four main parts : 1. A 750mm x 1000mm Core XY Laser Etcher/Cutter. This is the first part of a DIY laser engraver series, and you will find out all the important procedures that go into creating the core XY motion system of a laser engraver. on Introduction. I'm using the OpenBuilds ACRO 20"x40 platform, 6W OptLaser, homemade z height and the xPro driver board. The best part is making this cost barely half of what it takes to get a new one. Thanks, I received an A3 laser engraver for Christmas, I have put the frame work together got the laser light working. A 40w CO2 laser CNC machine is used for engraving holes and cutting different materials such as wood, plywood, acrylic. Hi.

DIR : Stepper motor direction control pin outs from the Arduino. Make your mini CNC laser machine at home with some common supplies such as plywood, steel rods, screws, clamps, sellotape, scissors, 3D beam lights, and others. That's the plan anyway.

I wanted to more easily adjust the height of the laser to accommodate various thicknesses of material, without having to manually loosen screws to adjust. First remove the protective layer of paper from the acrylic frames. 3 years ago I made this from A to Z at home by myself with reading and watching tones of videos. We have been working on the project since september 2015, and as it is a work in progress, a lot will be added later. Machine body: Sheet metal machine body and aluminum profile frame machine body. The most popular brand in China laser industry is Leadshine.

LASER: Laser module control pin number.Laser on/off should be 12 or 11 if using PWM mode (there's a jumper under the Arduino Nano to change this). The mechical parts are designed by myself because I had no mill to my use, so the mechnical parts are lasercut(same company as tube) steelplates welded together.

Register Today. I will write a short buildlog here with mostly pictures. details will follow, I rebuild my 2 meter tall 3D printer into a 100w laser cutter. Also it has to be able to cut through 10 millimetres thick acrylic material or 10 millimetres thick plywood. In software file there are lot of cool designs, you can use one of them. ROB CHESNEY 2 years ago It is a quick project as it can be finished within days or, at most, a week. Well, if you decided to go on a new challenge and create your own laser cutter machine for half the price, you are in luck, as this DIY tutorial would teach you step by step all the practice ways and processes to go about creating your own laser cutter. What am I doing wrong?

I will be posting the other required items very shortly. wechat: 15088276 008615920201400 info@fivelaser.com. Hi this is very good can you send dxf plaxsi model to my email?

The wiring is very simple.You have to connect the cables to the corresponding connector.

Then i decided to build my own laser, with some easier workflow and support for Windows 10. Continuous : Scans the head and pulses the laser - it is faster but less precise. They are composed of various, easy to get supplies you can purchase anywhere online or offline at any hardware store.

For example single phase motor such as 57HS09, 57HS15, 57HS22, and 3 phase motor such as 573S10, 573S15, 573S20, The linear guide rail commonly divide into micro square ball linear guide (Such as Hiwin and CPC brand) and wheel roller linear guide.

Built area. Set the COM PORT : Enter the COM Port number,which is earlier noted. Did you make this project? Or are you interested in the challenge of creating your laser cutter from scratch? You would totally love to check out this DIY tutorial guide. III. Could you please help me with acrylic dimensions for y axis (left and right motor mount) and x axis (motor and laser mount). Integrating custom machined components and off-the-shelf CNC components to create a portable diode laser etcher with air assist and reasonably substantial z-axis travel. STEP : Stepper motor pulse control pin outs from the Arduino. Now I am using a thick card board ( whose size is slightly larger then the engraver base surface ) for base platform.You can choose other materials also according to your situations. Can easily be swapped with the router. Thank you for the informative report. Anyone can start a successful blog, so why cant I (or you, too!)? I will publish photos and updates during my build continously. The recommended power output is 60-90W, this can also be increased with the use of an extension box. Hypothesis - Running CO2 laser tubes at high amperage may shoirten tube life in number of hours, but will be made up for by the increase in actual inches engraved/cut using the higher power.

Arduino powered simple CNC system using GRBL firmware. Participated in the Beyond the Comfort Zone Contest. As I have explained the details of assembling process in my video, I am not interested to write the long process : ).

I've followed all your instructions. This DIY tutorial guide shows how the laser cutter cuts all selected parts detailedly, then assembles the parts in their various places after painting them to your desired colors.

2 watt Laser Engraver, Simple, Fairly Low Cost, and Portable. MIN and MAX : To limit control pin PPM (Pulse-position modulation). all the parts have been printed at 65% infill a 2 perimeter lines just to make the parts stronger. New to building CNC. Created a small Z axis for the ACRO motion system. The optics and CNC( Computer Numerical Control) of lasers are used in directing the material or laser beams that are generated. :: Built from leftover T-Slot extrusions plates and hardware from other defunct projects. The Space Optimized LAser Cutter is a 40 watt CO2 laser cutter that supports a maximum part volume of 24" x 16" x 6.25". Can engrave items including Wood, plastic, bamboo, rubber, leather. Your Laser CNC can cut canvas (the fabric of backpacks) or leather? Knife table is very popular for hard material such as acrylic, wood, MDF and etc. JL3000 (with water pump), JL5000 (with water pump & compressor), JL5200 (with water pump & compressor for dual laser tube cooling), EMI filter, Switch power supply (Hengfu is best brand in China), Emergency stop button, laser button, scan button, key switch, Contactor, relay, Mother board (motion controller, control card), the famous controller such as RuiDa controller RD6442s, RD6442g.

Table of Contents They work by directing the output of a high-power laser, most commonly through cs. appreciate u can help me.thanks. I replaced the control board, but it does the same thing. Question This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register.  The area available for the build is 700x1200mm.

The area available for the build is 700x1200mm.

As you must have noticed, this isnt one of those very easy DIY projects, making a laser cutter takes time to complete, but with the right materials and guide, you should finish building yours in less than a week. From the beginning the cnc was built to fit/change between router, 5w led laser module and plotter pen. I designed this lasercutter in solidworks(not totally finished) for a good overview and such that the steel tubes could be lasercut by a company, the metal frame is based on the lasercutter the KSER, which you can find on cnczone.nl. Many OpenBuilds components are used, plus a handful of 3D printed parts.

This 40w CO2 laser cutter machine has a large cutting area of 1000 by 600mm and a touchscreen. Custom design parts, Copyright 2014, IO Rodeo. Step: Step is the distance moved when using the axis control buttons (does not change the output). I bought my unit in July and have been using it constantly. I have being doing all sorts of projects my whole life and Im always saying, Hey, that would make a good blog post! Finally, I decided to take the leap and put myself out there.

The frame is sized to hold 19" rack units so I'll build my control box into a 3U rack unit (also salvaged). With such great success/attention my laser got, I ended up with a good friend that would like to dabble in stencil art and so I have decided to share my build with him and you here :)

Is there a way to view it ? This is a 80w laser which I am building (picture of the case) the frame is constructed with normal square tubing with plastic corners. laser mini 20 * 40 OPENBUILDS base frame. 5. Building a custom made 80W Co2 Laser cutter. Hi sir.Will the firmware already exist in the software or will we have to write it ourselves? Before moving on to the next step wear Safety Goggles first. Both can be bought on ebay for cheap.

To cut down on cost I tried to have as many parts as possible be printed.

Again, same thing. In my first attempt I started to engrave by placing the machine over the table.After a fraction of second I noticed my table was burning.So be careful before engraving or cutting. 1.

A simple approach to making the Eleksmaker A3 Laser build have a better functioning X-Carriage!