Check for scratches or debris on the pipe and cut it as cleanly and squarely as possible.

They are put together by pushing the tube into the fitting. D.O.T. Follow any additional manufacturers instructions. SharkBite fittings also work with PEX tubing. Unlike gluing or soldering, the tubing does not need not be completely dry. Fittings can have between 1-6 inlet/outlet ports or may have additional functionality "What does Spigot mean?" is it hard to replace?Relieve the fuel system fuel pressure.Drain the fuel tank from the filler neck as much as possible.Raise and safely support the vehicle.Loosen the clamp and remove the filler hose from the fuel tank.Disconnect the fuel and EVAP quick-connect fittings at the fuel tank.Remove the exhaust pipe hangers and allow the exhaust system to drop slightly.More items

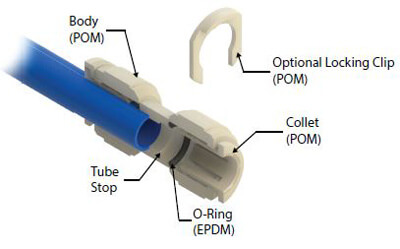

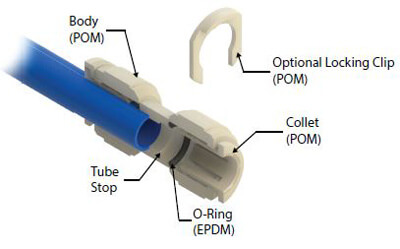

To begin, determine the pipes material. Nickel Plated Brass Push to Connect Fittings. To make sure that the pipe has been properly inserted, verify that the depth mark you made is within Push to Connect Composite Air Fitting - Male Straight. I have used and trust sharkbite fittings for 4 years. Add to cart. Push fit fittings also feature a neoprene O-ring that provides a leak-tight seal against pipes. They include brass, steel and stainless steel. Q. Often used in outdoor, damp, and washdown environments, these 316 stainless steel fittings will not corrode from water, salt, or chemicals. A. $1.62. TAILONZ PNEUMATIC 1/4 Inch od Push to Connect Fittings Pneumatic Fittings Kit 10 Spliters+10 Elbows+10 tee+10 Straight (40 pcs) Features : Product Name1/4 Plastic Push to connect fittings (40Pcs) Fluid Type All our push-in fittings are available in a wide range of configurations and materials and are easy to install. For example, Clippard recommends using our 85A durometer polyurethane tubing for barb fittings, and 95A durometer polyurethane tubing for push-quick fittings. Lets focus on Push to Connect fittings. Parker's complete range of compressed air push-to-connect fittings offers the most intuitive and efficient way to connect tubing to a pneumatic fitting. These valves open to allow flow in one direction and close when flow stops or reverses.. Acetal valves are more wear resistant than PVC valves.. Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60 F that will flow through a fully open valve with a difference of 1 psi between the Transition Composite Push to Connect Fittings. The process for making a connection on a square-cut, clean pipe is as follows. Push To Connect Composite Air Fitting - Male Elbow. Quick-connect fittings are rated to withstand pressure based on temperature and the fitting size. Swaging (/ s w e d /) is a forging process in which the dimensions of an item are altered using dies into which the item is forced. On average, composite push-to-connect fittings are about 43% lighter than brass push-to-connect. Push-Fit Fittings brass push fit fitting for a period of twenty-five (25) years from the date of manufacture. enable connectors and fittings to be attached to hoses in the field in low-pressure hydraulic and pneumatic I am installing an air suspension setup and am using 3/8 inch push-in style fittings. Compatible with PEX, copper, CPVC, PE-RT and HDPE pipe in any combination, the fittings come in a range of different sizes from inch to 2 inch. To ensure proper performance, quality and dependability of push to connect fittings, be sure to install the air line correctly: Cut the air line with a hose cutting tool. When you use them with PEX, however, you need to use the tube stiffener because you don't want the fitting to give way because the tubing size flexes. Pneumatic push-in fittings, also called push to connect fittings, provide a leak-free means of easily connecting hoses in your compressed air system. $2.24. 4. Simply push the fitting onto the PEX or copper pipe. Fig. Neoprene O-rings inside the fittings form tight, waterproof seals against the pipes. Push the pipe. good luck Renkenkyo:thumb: This means that the outside diameter will be 1/8" bigger than the "size" of the pipe. They are released by pushing the small collar into the fitting and then pulling out the tube. Sometimes they are slightly stuck, and may take a little bit more force to pull out the tube, but it should be if if the plastic collar is first pushed into the fitting. First: Push to Connect fittings, which are typically used for low-flow/pressure tubing applications. See the arrow in t "What does CTS mean?" The first one I hooked up and tested leaked(air was leaking from the area between the hose and the collar of the fitting, not where the fitting threads into the tank and not directly where the hose pushes in, but between the collar of the fitting and the fitting itself.). 3. This is because push to connect fittings employ a ring of metal spurs within the fittings that grip any pipe that is inserted into the fitting sockets. gio17vani. To disconnect, slide the Disconnect Clip over the fitting and it'll come right out. No Comments. Mostly for valves, repairs, and where a torch could do damage or set a blaze. All push-fits work using three primary elements: a collet featuring a ring of metal teeth that firmly grasps the pipe, one or more O-rings that create a watertight seal, and a locking mechanism that keeps everything together. Quickly and easily connect tubes and pipe in one simple step: Push to Connect the fittingthat's it!Visit us at: http://www.tifco.com 10 years ago. All push-fits work using three primary elements: a collet featuring a ring of metal teeth that firmly grasps the pipe, one or more O-rings that create a watertight seal, and a locking mechanism that keeps everything together. Find push-to-connect fittings, PEX tubing, disconnect clips and all of your plumbing supplies at: www.canarsee.com. SharkBite PEX-B is a cross-linked polyethylene tubing designed for use in residential and commercial plumbing applications. Metric Composite Push to Connect Fittings. But from my experience, changing the reverse osmosis I know the o rings can go bad over time and cause leaks. Hundreds of types of fittings and clamps can be used with plastic and rubber tubing. Push-in fittings. pipe connections without having to solder or use clamps, unions, or glue. The fittings are designed to work with CPVC, PEX, and hard drawn copper pipe (types K, L, M). Universal-Thread Stainless SteelPush-to-Connect Tube Fittings for Air and Water. SharkBite Brass PEX Barbed-Fittings and SharkBite Copper PEX Manifolds for a period of sixty (60) months from the date of manufacture. I'd like to see how this turns out so I keep an eye out on your progress. The warmer the water, the lower pressure the fitting will withstand. Barb fittings create a better seal on a slightly softer hose, while push-quick fittings are easier to use with stiffer hose. Composite Push to Connect Fittings. Metal Push to Connect Fittings - PN13 Series (Female Straight) $3.85. PEX, Copper, CPVC, PE-RT, and SDR-9 HDPE pipe are all Cut pipe squarely. Push-in fittings. Inch Composite Push to Connect Fittings. How to Apply Push-to-Connect Fittings Identify pipe material. Reliance Worldwide Corp.'s SharkBite Push-to-Connect Transition Fittings. 3. Add to cart. These fittings work great with copper, whereas, some other push -to- connect fittings work better with plastic connections. However, with PTC fittings, make sure they are suitable for vacuum use. These "push to connect" fittings can be used in a wide variety of applications corresponding to many industrial markets When pressing a fitting into the hose, the hose expands slightly to accommodate the larger diameter of the fittings barbs. Once the hose is completely pushed onto the fitting and into the yellow cap, the internal liner material conforms to the barbs under the pressure of the braid and the outer skin of the hose. The ability to make a fast and reliable connection is the most significant benefit of Push to Connect fittings. Buy on Amazon. P-T-C Elbows P-T-C Tees The ability to make a fast and reliable connection is the most significant benefit of Push to Connect fittings. 6). I'd never seen a push to connect fitting for a water cool set up. Push the tubing into the fitting, and the push-lock system will do the rest. Push-to-pull, push-to-connect, push-in, push-fit, or instant fittings are a type of easily removed compression fitting or quick connect fitting that allows an air (or water) line to be attached, nominally without the use of tools (a tool is still usually required for cutting tubing to length and removal). Using Quick Connect FittingsFiltration SystemsCartridgesParts Push-to-Connect fittings, also know as Push fittings, are very convenient and easy to install. Use the Recommended Fittings & Clamps section found at each tubing and hose product to guide you in your selection, or contact a Fluid Transfer Using a slight twisting motion, push the pipe firmly into the SharkBite fitting until you hit the tube stop. Fittings can have between 1-6 inlet/outlet ports or may have additional functionality Push the pipe into the fitting per the manufacturers instructions. NewAges push-to-connect fittings, called Newloc, are available in both plastic and brass. 3. Ensure proper placement. All our push-in fittings are available in a wide range of configurations and materials and are easy to install. A. CTS stands for "copper tube size" which is a nominal pipe size. Click to see full answer Regarding this, how do push fittings work? Push-to-connect fittings use an internal collet and external push button to connect tubing.The leak free design make an easy connection with no tools necessary. Read More. boil a kettle of water ..put the end of the hose in it for five mins . Insta-grip, pipefitters in our plant use a dab of vaseline on the barbed fitting. That said, you need to be a gorilla to seat a 3/4" hose. A couple techniques workif you can rock the hose thru an arc while you push it somehow helps it to "inch" onto the barbs. Pneumatic push-in fittings, also called push to connect fittings, provide a leak-free means of easily connecting hoses in your compressed air system. Buy on Amazon. Metric Stainless Steel Push to Connect Fittings. The term swage may apply to the process (verb) or to Of course nowadays the most popular fitting choice for PU tubing would be a push-to-connect (PTC) or push-in fitting (Fig. How They Work. PEX pipe is flexible and easy to work with, which reduces the number of fittings needed to complete a job; reducing cost and leak points. Type:1/4 Od x 1/4 Tube Od Push to Connect Air Tube Fittings; Body Style: 90Degree Elbow Push in fitting 1/4 Stainless Steel elbow tube fittings Fluid Admitted: Air, Water (No Freezing) 1/4 union elbow quick connect fittings Working Pressure:0-1.0mpa | 0-150psi; Proof Pressure:3.0Mpa | 435psi; Negative Pressure:-100Kpa | -29.5 In Hg Remove any Measure and Mark. Second: Quick-connect fittings, which are used in higher pressure pneumatic, hydraulic, gas, steam, and vacuum applications. Our goal at NewAge Industries is to offer a good cross section of fittings to efficiently connect our tubing and hose products.

Quick-connect fittings are rated to withstand pressure based on temperature and the fitting size. Swaging (/ s w e d /) is a forging process in which the dimensions of an item are altered using dies into which the item is forced. On average, composite push-to-connect fittings are about 43% lighter than brass push-to-connect. Push-Fit Fittings brass push fit fitting for a period of twenty-five (25) years from the date of manufacture. enable connectors and fittings to be attached to hoses in the field in low-pressure hydraulic and pneumatic I am installing an air suspension setup and am using 3/8 inch push-in style fittings. Compatible with PEX, copper, CPVC, PE-RT and HDPE pipe in any combination, the fittings come in a range of different sizes from inch to 2 inch. To ensure proper performance, quality and dependability of push to connect fittings, be sure to install the air line correctly: Cut the air line with a hose cutting tool. When you use them with PEX, however, you need to use the tube stiffener because you don't want the fitting to give way because the tubing size flexes. Pneumatic push-in fittings, also called push to connect fittings, provide a leak-free means of easily connecting hoses in your compressed air system. $2.24. 4. Simply push the fitting onto the PEX or copper pipe. Fig. Neoprene O-rings inside the fittings form tight, waterproof seals against the pipes. Push the pipe. good luck Renkenkyo:thumb: This means that the outside diameter will be 1/8" bigger than the "size" of the pipe. They are released by pushing the small collar into the fitting and then pulling out the tube. Sometimes they are slightly stuck, and may take a little bit more force to pull out the tube, but it should be if if the plastic collar is first pushed into the fitting. First: Push to Connect fittings, which are typically used for low-flow/pressure tubing applications. See the arrow in t "What does CTS mean?" The first one I hooked up and tested leaked(air was leaking from the area between the hose and the collar of the fitting, not where the fitting threads into the tank and not directly where the hose pushes in, but between the collar of the fitting and the fitting itself.). 3. This is because push to connect fittings employ a ring of metal spurs within the fittings that grip any pipe that is inserted into the fitting sockets. gio17vani. To disconnect, slide the Disconnect Clip over the fitting and it'll come right out. No Comments. Mostly for valves, repairs, and where a torch could do damage or set a blaze. All push-fits work using three primary elements: a collet featuring a ring of metal teeth that firmly grasps the pipe, one or more O-rings that create a watertight seal, and a locking mechanism that keeps everything together. Quickly and easily connect tubes and pipe in one simple step: Push to Connect the fittingthat's it!Visit us at: http://www.tifco.com 10 years ago. All push-fits work using three primary elements: a collet featuring a ring of metal teeth that firmly grasps the pipe, one or more O-rings that create a watertight seal, and a locking mechanism that keeps everything together. Find push-to-connect fittings, PEX tubing, disconnect clips and all of your plumbing supplies at: www.canarsee.com. SharkBite PEX-B is a cross-linked polyethylene tubing designed for use in residential and commercial plumbing applications. Metric Composite Push to Connect Fittings. But from my experience, changing the reverse osmosis I know the o rings can go bad over time and cause leaks. Hundreds of types of fittings and clamps can be used with plastic and rubber tubing. Push-in fittings. pipe connections without having to solder or use clamps, unions, or glue. The fittings are designed to work with CPVC, PEX, and hard drawn copper pipe (types K, L, M). Universal-Thread Stainless SteelPush-to-Connect Tube Fittings for Air and Water. SharkBite Brass PEX Barbed-Fittings and SharkBite Copper PEX Manifolds for a period of sixty (60) months from the date of manufacture. I'd like to see how this turns out so I keep an eye out on your progress. The warmer the water, the lower pressure the fitting will withstand. Barb fittings create a better seal on a slightly softer hose, while push-quick fittings are easier to use with stiffer hose. Composite Push to Connect Fittings. Metal Push to Connect Fittings - PN13 Series (Female Straight) $3.85. PEX, Copper, CPVC, PE-RT, and SDR-9 HDPE pipe are all Cut pipe squarely. Push-in fittings. Inch Composite Push to Connect Fittings. How to Apply Push-to-Connect Fittings Identify pipe material. Reliance Worldwide Corp.'s SharkBite Push-to-Connect Transition Fittings. 3. Add to cart. These fittings work great with copper, whereas, some other push -to- connect fittings work better with plastic connections. However, with PTC fittings, make sure they are suitable for vacuum use. These "push to connect" fittings can be used in a wide variety of applications corresponding to many industrial markets When pressing a fitting into the hose, the hose expands slightly to accommodate the larger diameter of the fittings barbs. Once the hose is completely pushed onto the fitting and into the yellow cap, the internal liner material conforms to the barbs under the pressure of the braid and the outer skin of the hose. The ability to make a fast and reliable connection is the most significant benefit of Push to Connect fittings. Buy on Amazon. P-T-C Elbows P-T-C Tees The ability to make a fast and reliable connection is the most significant benefit of Push to Connect fittings. 6). I'd never seen a push to connect fitting for a water cool set up. Push the tubing into the fitting, and the push-lock system will do the rest. Push-to-pull, push-to-connect, push-in, push-fit, or instant fittings are a type of easily removed compression fitting or quick connect fitting that allows an air (or water) line to be attached, nominally without the use of tools (a tool is still usually required for cutting tubing to length and removal). Using Quick Connect FittingsFiltration SystemsCartridgesParts Push-to-Connect fittings, also know as Push fittings, are very convenient and easy to install. Use the Recommended Fittings & Clamps section found at each tubing and hose product to guide you in your selection, or contact a Fluid Transfer Using a slight twisting motion, push the pipe firmly into the SharkBite fitting until you hit the tube stop. Fittings can have between 1-6 inlet/outlet ports or may have additional functionality Push the pipe into the fitting per the manufacturers instructions. NewAges push-to-connect fittings, called Newloc, are available in both plastic and brass. 3. Ensure proper placement. All our push-in fittings are available in a wide range of configurations and materials and are easy to install. A. CTS stands for "copper tube size" which is a nominal pipe size. Click to see full answer Regarding this, how do push fittings work? Push-to-connect fittings use an internal collet and external push button to connect tubing.The leak free design make an easy connection with no tools necessary. Read More. boil a kettle of water ..put the end of the hose in it for five mins . Insta-grip, pipefitters in our plant use a dab of vaseline on the barbed fitting. That said, you need to be a gorilla to seat a 3/4" hose. A couple techniques workif you can rock the hose thru an arc while you push it somehow helps it to "inch" onto the barbs. Pneumatic push-in fittings, also called push to connect fittings, provide a leak-free means of easily connecting hoses in your compressed air system. Buy on Amazon. Metric Stainless Steel Push to Connect Fittings. The term swage may apply to the process (verb) or to Of course nowadays the most popular fitting choice for PU tubing would be a push-to-connect (PTC) or push-in fitting (Fig. How They Work. PEX pipe is flexible and easy to work with, which reduces the number of fittings needed to complete a job; reducing cost and leak points. Type:1/4 Od x 1/4 Tube Od Push to Connect Air Tube Fittings; Body Style: 90Degree Elbow Push in fitting 1/4 Stainless Steel elbow tube fittings Fluid Admitted: Air, Water (No Freezing) 1/4 union elbow quick connect fittings Working Pressure:0-1.0mpa | 0-150psi; Proof Pressure:3.0Mpa | 435psi; Negative Pressure:-100Kpa | -29.5 In Hg Remove any Measure and Mark. Second: Quick-connect fittings, which are used in higher pressure pneumatic, hydraulic, gas, steam, and vacuum applications. Our goal at NewAge Industries is to offer a good cross section of fittings to efficiently connect our tubing and hose products.

I have repaired a few Lets take a closer look. Q. 3. How They Work. Often used in outdoor, damp, and washdown environments, these 316 stainless steel fittings will not corrode from water, salt, or chemicals. Installing a push-fit plumbing fitting isn't much harder than putting a cap onto a pen. Once the pipe is cut, cleaned and marked for the fitting depth, all you have to do is push the fitting onto the pipe for a permanentyet removableconnection. It's that easy, and it's almost that foolproof. Insert tubing into the push-to-connect fittings no heat, solder, or flux required. Push to connect fittings are easy to use and can be utilized in a variety of applications. The barrel has three annular barbs and a tell-tale yellow cap covers the end of the. Whether you need to connect two pieces of tubing or join a tube to a fitting, these fittings provide a quick and easy way to make leak-free connections. Spigot references one side of a fitting that will fit inside a "push-fit" fitting. Push -Lok fittings are designed and manufactured with a specialized set of barbs that connect the hose to a vast number of different connections made of different metals compatible with the fluids they will carry. Stainless Steel Push to Connect Fittings. The manufacturer of "push-fit" fittings refers to this as a "stem". They are available in various sizes and configurations to meet the needs of any application. Push-to-connect fittings conform to the ASSE 1067 standard. Push-To-Connect. PEX is also extremely durable and corrosion/freeze resistant. This will ensure a clean square cut without deforming the air line. TAILONZ PNEUMATIC 1/4 Inch od Push to Connect Fittings Pneumatic Fittings Kit 10 Spliters+10 Elbows+10 tee+10 Straight (40 pcs) Features : Product Name1/4 Plastic Push to connect fittings (40Pcs) Fluid Type Universal-Thread Stainless SteelPush-to-Connect Tube Fittings for Air and Water. 7 shows a vacuum venturi that also uses PTC technology. TAILONZ PNEUMATIC 1/4 Inch od Push to Connect Fittings Pneumatic Fittings Kit 10 Spliters+10 Elbows+10 tee+10 Straight (40 pcs) Features : Product Name1/4 Plastic Push to connect fittings (40Pcs) Fluid Type Whether a new installation or an emergency repair, saving time is saving money. The larger the tubing and more rigid the tubing, the more pressure the fitting can withstand. These "push to connect" fittings can be used in a wide variety of applications corresponding to many industrial markets These fittings are popular due to their light weight and durable construction. Buy on Amazon. All About Push-Fit Plumbing Fittings and How They Work.The fittings are engineered with a ring of metal spurs inside the fittings that tightly grip the pipes when they are inserted into the fitting sockets. July 8, 2020. Add to cart. Push the fitting straight onto the end of the pipe (or push the pipe straight into the fitting, as applicable) until the pipe stops inside the fitting. SharkBite PEX-B is a cross-linked polyethylene The fittings are designed to work with CPVC, PEX, and hard drawn copper pipe (types K, L, M). The weight difference is significant enough to affect fuel efficiency and payload potential. Parker's complete range of compressed air push-to-connect fittings offers the most intuitive and efficient way to connect tubing to a pneumatic fitting. Swaging is usually a cold working process, but also may be hot worked.. When making joints for new installation or repair using brass tube, PEX or CPVC, Push to Connect fittings are the easiest and fastest method to provide an air or fluid tight seal when the tube or pipe is inserted. All other valves and accessories sold under Cash Acme’s brand names of the SharkBite Use the Recommended Fittings & Clamps section found at each tubing and hose product to guide you in your selection, or contact a Fluid Transfer Specialist at 215-526-2300 or esales@newageindustries.com for assistance with building your system. Depending on the fitting, insert a stiffening sleeve into the PEX pipe. This has to do with the expansion and contraction of the plastics.

They are put together by pushing the tube into the fitting. D.O.T. Follow any additional manufacturers instructions. SharkBite fittings also work with PEX tubing. Unlike gluing or soldering, the tubing does not need not be completely dry. Fittings can have between 1-6 inlet/outlet ports or may have additional functionality "What does Spigot mean?" is it hard to replace?Relieve the fuel system fuel pressure.Drain the fuel tank from the filler neck as much as possible.Raise and safely support the vehicle.Loosen the clamp and remove the filler hose from the fuel tank.Disconnect the fuel and EVAP quick-connect fittings at the fuel tank.Remove the exhaust pipe hangers and allow the exhaust system to drop slightly.More items

To begin, determine the pipes material. Nickel Plated Brass Push to Connect Fittings. To make sure that the pipe has been properly inserted, verify that the depth mark you made is within Push to Connect Composite Air Fitting - Male Straight. I have used and trust sharkbite fittings for 4 years. Add to cart. Push fit fittings also feature a neoprene O-ring that provides a leak-tight seal against pipes. They include brass, steel and stainless steel. Q. Often used in outdoor, damp, and washdown environments, these 316 stainless steel fittings will not corrode from water, salt, or chemicals. A. $1.62. TAILONZ PNEUMATIC 1/4 Inch od Push to Connect Fittings Pneumatic Fittings Kit 10 Spliters+10 Elbows+10 tee+10 Straight (40 pcs) Features : Product Name1/4 Plastic Push to connect fittings (40Pcs) Fluid Type All our push-in fittings are available in a wide range of configurations and materials and are easy to install. For example, Clippard recommends using our 85A durometer polyurethane tubing for barb fittings, and 95A durometer polyurethane tubing for push-quick fittings. Lets focus on Push to Connect fittings. Parker's complete range of compressed air push-to-connect fittings offers the most intuitive and efficient way to connect tubing to a pneumatic fitting. These valves open to allow flow in one direction and close when flow stops or reverses.. Acetal valves are more wear resistant than PVC valves.. Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60 F that will flow through a fully open valve with a difference of 1 psi between the Transition Composite Push to Connect Fittings. The process for making a connection on a square-cut, clean pipe is as follows. Push To Connect Composite Air Fitting - Male Elbow.

Quick-connect fittings are rated to withstand pressure based on temperature and the fitting size. Swaging (/ s w e d /) is a forging process in which the dimensions of an item are altered using dies into which the item is forced. On average, composite push-to-connect fittings are about 43% lighter than brass push-to-connect. Push-Fit Fittings brass push fit fitting for a period of twenty-five (25) years from the date of manufacture. enable connectors and fittings to be attached to hoses in the field in low-pressure hydraulic and pneumatic I am installing an air suspension setup and am using 3/8 inch push-in style fittings. Compatible with PEX, copper, CPVC, PE-RT and HDPE pipe in any combination, the fittings come in a range of different sizes from inch to 2 inch. To ensure proper performance, quality and dependability of push to connect fittings, be sure to install the air line correctly: Cut the air line with a hose cutting tool. When you use them with PEX, however, you need to use the tube stiffener because you don't want the fitting to give way because the tubing size flexes. Pneumatic push-in fittings, also called push to connect fittings, provide a leak-free means of easily connecting hoses in your compressed air system. $2.24. 4. Simply push the fitting onto the PEX or copper pipe. Fig. Neoprene O-rings inside the fittings form tight, waterproof seals against the pipes. Push the pipe. good luck Renkenkyo:thumb: This means that the outside diameter will be 1/8" bigger than the "size" of the pipe. They are released by pushing the small collar into the fitting and then pulling out the tube. Sometimes they are slightly stuck, and may take a little bit more force to pull out the tube, but it should be if if the plastic collar is first pushed into the fitting. First: Push to Connect fittings, which are typically used for low-flow/pressure tubing applications. See the arrow in t "What does CTS mean?" The first one I hooked up and tested leaked(air was leaking from the area between the hose and the collar of the fitting, not where the fitting threads into the tank and not directly where the hose pushes in, but between the collar of the fitting and the fitting itself.). 3. This is because push to connect fittings employ a ring of metal spurs within the fittings that grip any pipe that is inserted into the fitting sockets. gio17vani. To disconnect, slide the Disconnect Clip over the fitting and it'll come right out. No Comments. Mostly for valves, repairs, and where a torch could do damage or set a blaze. All push-fits work using three primary elements: a collet featuring a ring of metal teeth that firmly grasps the pipe, one or more O-rings that create a watertight seal, and a locking mechanism that keeps everything together. Quickly and easily connect tubes and pipe in one simple step: Push to Connect the fittingthat's it!Visit us at: http://www.tifco.com 10 years ago. All push-fits work using three primary elements: a collet featuring a ring of metal teeth that firmly grasps the pipe, one or more O-rings that create a watertight seal, and a locking mechanism that keeps everything together. Find push-to-connect fittings, PEX tubing, disconnect clips and all of your plumbing supplies at: www.canarsee.com. SharkBite PEX-B is a cross-linked polyethylene tubing designed for use in residential and commercial plumbing applications. Metric Composite Push to Connect Fittings. But from my experience, changing the reverse osmosis I know the o rings can go bad over time and cause leaks. Hundreds of types of fittings and clamps can be used with plastic and rubber tubing. Push-in fittings. pipe connections without having to solder or use clamps, unions, or glue. The fittings are designed to work with CPVC, PEX, and hard drawn copper pipe (types K, L, M). Universal-Thread Stainless SteelPush-to-Connect Tube Fittings for Air and Water. SharkBite Brass PEX Barbed-Fittings and SharkBite Copper PEX Manifolds for a period of sixty (60) months from the date of manufacture. I'd like to see how this turns out so I keep an eye out on your progress. The warmer the water, the lower pressure the fitting will withstand. Barb fittings create a better seal on a slightly softer hose, while push-quick fittings are easier to use with stiffer hose. Composite Push to Connect Fittings. Metal Push to Connect Fittings - PN13 Series (Female Straight) $3.85. PEX, Copper, CPVC, PE-RT, and SDR-9 HDPE pipe are all Cut pipe squarely. Push-in fittings. Inch Composite Push to Connect Fittings. How to Apply Push-to-Connect Fittings Identify pipe material. Reliance Worldwide Corp.'s SharkBite Push-to-Connect Transition Fittings. 3. Add to cart. These fittings work great with copper, whereas, some other push -to- connect fittings work better with plastic connections. However, with PTC fittings, make sure they are suitable for vacuum use. These "push to connect" fittings can be used in a wide variety of applications corresponding to many industrial markets When pressing a fitting into the hose, the hose expands slightly to accommodate the larger diameter of the fittings barbs. Once the hose is completely pushed onto the fitting and into the yellow cap, the internal liner material conforms to the barbs under the pressure of the braid and the outer skin of the hose. The ability to make a fast and reliable connection is the most significant benefit of Push to Connect fittings. Buy on Amazon. P-T-C Elbows P-T-C Tees The ability to make a fast and reliable connection is the most significant benefit of Push to Connect fittings. 6). I'd never seen a push to connect fitting for a water cool set up. Push the tubing into the fitting, and the push-lock system will do the rest. Push-to-pull, push-to-connect, push-in, push-fit, or instant fittings are a type of easily removed compression fitting or quick connect fitting that allows an air (or water) line to be attached, nominally without the use of tools (a tool is still usually required for cutting tubing to length and removal). Using Quick Connect FittingsFiltration SystemsCartridgesParts Push-to-Connect fittings, also know as Push fittings, are very convenient and easy to install. Use the Recommended Fittings & Clamps section found at each tubing and hose product to guide you in your selection, or contact a Fluid Transfer Using a slight twisting motion, push the pipe firmly into the SharkBite fitting until you hit the tube stop. Fittings can have between 1-6 inlet/outlet ports or may have additional functionality Push the pipe into the fitting per the manufacturers instructions. NewAges push-to-connect fittings, called Newloc, are available in both plastic and brass. 3. Ensure proper placement. All our push-in fittings are available in a wide range of configurations and materials and are easy to install. A. CTS stands for "copper tube size" which is a nominal pipe size. Click to see full answer Regarding this, how do push fittings work? Push-to-connect fittings use an internal collet and external push button to connect tubing.The leak free design make an easy connection with no tools necessary. Read More. boil a kettle of water ..put the end of the hose in it for five mins . Insta-grip, pipefitters in our plant use a dab of vaseline on the barbed fitting. That said, you need to be a gorilla to seat a 3/4" hose. A couple techniques workif you can rock the hose thru an arc while you push it somehow helps it to "inch" onto the barbs. Pneumatic push-in fittings, also called push to connect fittings, provide a leak-free means of easily connecting hoses in your compressed air system. Buy on Amazon. Metric Stainless Steel Push to Connect Fittings. The term swage may apply to the process (verb) or to Of course nowadays the most popular fitting choice for PU tubing would be a push-to-connect (PTC) or push-in fitting (Fig. How They Work. PEX pipe is flexible and easy to work with, which reduces the number of fittings needed to complete a job; reducing cost and leak points. Type:1/4 Od x 1/4 Tube Od Push to Connect Air Tube Fittings; Body Style: 90Degree Elbow Push in fitting 1/4 Stainless Steel elbow tube fittings Fluid Admitted: Air, Water (No Freezing) 1/4 union elbow quick connect fittings Working Pressure:0-1.0mpa | 0-150psi; Proof Pressure:3.0Mpa | 435psi; Negative Pressure:-100Kpa | -29.5 In Hg Remove any Measure and Mark. Second: Quick-connect fittings, which are used in higher pressure pneumatic, hydraulic, gas, steam, and vacuum applications. Our goal at NewAge Industries is to offer a good cross section of fittings to efficiently connect our tubing and hose products.

Quick-connect fittings are rated to withstand pressure based on temperature and the fitting size. Swaging (/ s w e d /) is a forging process in which the dimensions of an item are altered using dies into which the item is forced. On average, composite push-to-connect fittings are about 43% lighter than brass push-to-connect. Push-Fit Fittings brass push fit fitting for a period of twenty-five (25) years from the date of manufacture. enable connectors and fittings to be attached to hoses in the field in low-pressure hydraulic and pneumatic I am installing an air suspension setup and am using 3/8 inch push-in style fittings. Compatible with PEX, copper, CPVC, PE-RT and HDPE pipe in any combination, the fittings come in a range of different sizes from inch to 2 inch. To ensure proper performance, quality and dependability of push to connect fittings, be sure to install the air line correctly: Cut the air line with a hose cutting tool. When you use them with PEX, however, you need to use the tube stiffener because you don't want the fitting to give way because the tubing size flexes. Pneumatic push-in fittings, also called push to connect fittings, provide a leak-free means of easily connecting hoses in your compressed air system. $2.24. 4. Simply push the fitting onto the PEX or copper pipe. Fig. Neoprene O-rings inside the fittings form tight, waterproof seals against the pipes. Push the pipe. good luck Renkenkyo:thumb: This means that the outside diameter will be 1/8" bigger than the "size" of the pipe. They are released by pushing the small collar into the fitting and then pulling out the tube. Sometimes they are slightly stuck, and may take a little bit more force to pull out the tube, but it should be if if the plastic collar is first pushed into the fitting. First: Push to Connect fittings, which are typically used for low-flow/pressure tubing applications. See the arrow in t "What does CTS mean?" The first one I hooked up and tested leaked(air was leaking from the area between the hose and the collar of the fitting, not where the fitting threads into the tank and not directly where the hose pushes in, but between the collar of the fitting and the fitting itself.). 3. This is because push to connect fittings employ a ring of metal spurs within the fittings that grip any pipe that is inserted into the fitting sockets. gio17vani. To disconnect, slide the Disconnect Clip over the fitting and it'll come right out. No Comments. Mostly for valves, repairs, and where a torch could do damage or set a blaze. All push-fits work using three primary elements: a collet featuring a ring of metal teeth that firmly grasps the pipe, one or more O-rings that create a watertight seal, and a locking mechanism that keeps everything together. Quickly and easily connect tubes and pipe in one simple step: Push to Connect the fittingthat's it!Visit us at: http://www.tifco.com 10 years ago. All push-fits work using three primary elements: a collet featuring a ring of metal teeth that firmly grasps the pipe, one or more O-rings that create a watertight seal, and a locking mechanism that keeps everything together. Find push-to-connect fittings, PEX tubing, disconnect clips and all of your plumbing supplies at: www.canarsee.com. SharkBite PEX-B is a cross-linked polyethylene tubing designed for use in residential and commercial plumbing applications. Metric Composite Push to Connect Fittings. But from my experience, changing the reverse osmosis I know the o rings can go bad over time and cause leaks. Hundreds of types of fittings and clamps can be used with plastic and rubber tubing. Push-in fittings. pipe connections without having to solder or use clamps, unions, or glue. The fittings are designed to work with CPVC, PEX, and hard drawn copper pipe (types K, L, M). Universal-Thread Stainless SteelPush-to-Connect Tube Fittings for Air and Water. SharkBite Brass PEX Barbed-Fittings and SharkBite Copper PEX Manifolds for a period of sixty (60) months from the date of manufacture. I'd like to see how this turns out so I keep an eye out on your progress. The warmer the water, the lower pressure the fitting will withstand. Barb fittings create a better seal on a slightly softer hose, while push-quick fittings are easier to use with stiffer hose. Composite Push to Connect Fittings. Metal Push to Connect Fittings - PN13 Series (Female Straight) $3.85. PEX, Copper, CPVC, PE-RT, and SDR-9 HDPE pipe are all Cut pipe squarely. Push-in fittings. Inch Composite Push to Connect Fittings. How to Apply Push-to-Connect Fittings Identify pipe material. Reliance Worldwide Corp.'s SharkBite Push-to-Connect Transition Fittings. 3. Add to cart. These fittings work great with copper, whereas, some other push -to- connect fittings work better with plastic connections. However, with PTC fittings, make sure they are suitable for vacuum use. These "push to connect" fittings can be used in a wide variety of applications corresponding to many industrial markets When pressing a fitting into the hose, the hose expands slightly to accommodate the larger diameter of the fittings barbs. Once the hose is completely pushed onto the fitting and into the yellow cap, the internal liner material conforms to the barbs under the pressure of the braid and the outer skin of the hose. The ability to make a fast and reliable connection is the most significant benefit of Push to Connect fittings. Buy on Amazon. P-T-C Elbows P-T-C Tees The ability to make a fast and reliable connection is the most significant benefit of Push to Connect fittings. 6). I'd never seen a push to connect fitting for a water cool set up. Push the tubing into the fitting, and the push-lock system will do the rest. Push-to-pull, push-to-connect, push-in, push-fit, or instant fittings are a type of easily removed compression fitting or quick connect fitting that allows an air (or water) line to be attached, nominally without the use of tools (a tool is still usually required for cutting tubing to length and removal). Using Quick Connect FittingsFiltration SystemsCartridgesParts Push-to-Connect fittings, also know as Push fittings, are very convenient and easy to install. Use the Recommended Fittings & Clamps section found at each tubing and hose product to guide you in your selection, or contact a Fluid Transfer Using a slight twisting motion, push the pipe firmly into the SharkBite fitting until you hit the tube stop. Fittings can have between 1-6 inlet/outlet ports or may have additional functionality Push the pipe into the fitting per the manufacturers instructions. NewAges push-to-connect fittings, called Newloc, are available in both plastic and brass. 3. Ensure proper placement. All our push-in fittings are available in a wide range of configurations and materials and are easy to install. A. CTS stands for "copper tube size" which is a nominal pipe size. Click to see full answer Regarding this, how do push fittings work? Push-to-connect fittings use an internal collet and external push button to connect tubing.The leak free design make an easy connection with no tools necessary. Read More. boil a kettle of water ..put the end of the hose in it for five mins . Insta-grip, pipefitters in our plant use a dab of vaseline on the barbed fitting. That said, you need to be a gorilla to seat a 3/4" hose. A couple techniques workif you can rock the hose thru an arc while you push it somehow helps it to "inch" onto the barbs. Pneumatic push-in fittings, also called push to connect fittings, provide a leak-free means of easily connecting hoses in your compressed air system. Buy on Amazon. Metric Stainless Steel Push to Connect Fittings. The term swage may apply to the process (verb) or to Of course nowadays the most popular fitting choice for PU tubing would be a push-to-connect (PTC) or push-in fitting (Fig. How They Work. PEX pipe is flexible and easy to work with, which reduces the number of fittings needed to complete a job; reducing cost and leak points. Type:1/4 Od x 1/4 Tube Od Push to Connect Air Tube Fittings; Body Style: 90Degree Elbow Push in fitting 1/4 Stainless Steel elbow tube fittings Fluid Admitted: Air, Water (No Freezing) 1/4 union elbow quick connect fittings Working Pressure:0-1.0mpa | 0-150psi; Proof Pressure:3.0Mpa | 435psi; Negative Pressure:-100Kpa | -29.5 In Hg Remove any Measure and Mark. Second: Quick-connect fittings, which are used in higher pressure pneumatic, hydraulic, gas, steam, and vacuum applications. Our goal at NewAge Industries is to offer a good cross section of fittings to efficiently connect our tubing and hose products. I have repaired a few Lets take a closer look. Q. 3. How They Work. Often used in outdoor, damp, and washdown environments, these 316 stainless steel fittings will not corrode from water, salt, or chemicals. Installing a push-fit plumbing fitting isn't much harder than putting a cap onto a pen. Once the pipe is cut, cleaned and marked for the fitting depth, all you have to do is push the fitting onto the pipe for a permanentyet removableconnection. It's that easy, and it's almost that foolproof. Insert tubing into the push-to-connect fittings no heat, solder, or flux required. Push to connect fittings are easy to use and can be utilized in a variety of applications. The barrel has three annular barbs and a tell-tale yellow cap covers the end of the. Whether you need to connect two pieces of tubing or join a tube to a fitting, these fittings provide a quick and easy way to make leak-free connections. Spigot references one side of a fitting that will fit inside a "push-fit" fitting. Push -Lok fittings are designed and manufactured with a specialized set of barbs that connect the hose to a vast number of different connections made of different metals compatible with the fluids they will carry. Stainless Steel Push to Connect Fittings. The manufacturer of "push-fit" fittings refers to this as a "stem". They are available in various sizes and configurations to meet the needs of any application. Push-to-connect fittings conform to the ASSE 1067 standard. Push-To-Connect. PEX is also extremely durable and corrosion/freeze resistant. This will ensure a clean square cut without deforming the air line. TAILONZ PNEUMATIC 1/4 Inch od Push to Connect Fittings Pneumatic Fittings Kit 10 Spliters+10 Elbows+10 tee+10 Straight (40 pcs) Features : Product Name1/4 Plastic Push to connect fittings (40Pcs) Fluid Type Universal-Thread Stainless SteelPush-to-Connect Tube Fittings for Air and Water. 7 shows a vacuum venturi that also uses PTC technology. TAILONZ PNEUMATIC 1/4 Inch od Push to Connect Fittings Pneumatic Fittings Kit 10 Spliters+10 Elbows+10 tee+10 Straight (40 pcs) Features : Product Name1/4 Plastic Push to connect fittings (40Pcs) Fluid Type Whether a new installation or an emergency repair, saving time is saving money. The larger the tubing and more rigid the tubing, the more pressure the fitting can withstand. These "push to connect" fittings can be used in a wide variety of applications corresponding to many industrial markets These fittings are popular due to their light weight and durable construction. Buy on Amazon. All About Push-Fit Plumbing Fittings and How They Work.The fittings are engineered with a ring of metal spurs inside the fittings that tightly grip the pipes when they are inserted into the fitting sockets. July 8, 2020. Add to cart. Push the fitting straight onto the end of the pipe (or push the pipe straight into the fitting, as applicable) until the pipe stops inside the fitting. SharkBite PEX-B is a cross-linked polyethylene The fittings are designed to work with CPVC, PEX, and hard drawn copper pipe (types K, L, M). The weight difference is significant enough to affect fuel efficiency and payload potential. Parker's complete range of compressed air push-to-connect fittings offers the most intuitive and efficient way to connect tubing to a pneumatic fitting. Swaging is usually a cold working process, but also may be hot worked.. When making joints for new installation or repair using brass tube, PEX or CPVC, Push to Connect fittings are the easiest and fastest method to provide an air or fluid tight seal when the tube or pipe is inserted. All other valves and accessories sold under Cash Acme’s brand names of the SharkBite Use the Recommended Fittings & Clamps section found at each tubing and hose product to guide you in your selection, or contact a Fluid Transfer Specialist at 215-526-2300 or esales@newageindustries.com for assistance with building your system. Depending on the fitting, insert a stiffening sleeve into the PEX pipe. This has to do with the expansion and contraction of the plastics.