TRANSFORMERS, Second Ed., Bharat Heavy Electricals Limited Bhopal (M P), Tata McGraw-Hill Publishing Company Limited, 2003. Some modes of failure can occur regardless of construction type. Here, a case study of four distribution transformers which failed within warranty period of three years is presented and causes of failure are analyzed. nonlinear loads, in offices, industries as well aswindings was found in burnt conditionas shown in FigurIJeSER 2014 http://www.ijser.org. Now let's try to another three important factors which could also lead to the failure of the distribution transformers : Probably one of the most important factor in transformer life is the level of the craftsmanship, the quality of manufacturing process and controls placed to keep a check on the process. A dielectric breakdown can also be the result of mechanical forces tearing the insulation.

For liquid filled transformers, the traditional insulation system consists of oil and paper. Government of Madhya Pradesh has given one point legal connections per family free of cost to all economically weak families in both rural and urban areas. samples lies between 0.224 and 0.336. Cost efficiency since necessary repair works can be properly scheduled. Increase in acid value of insulating oil due to thermal aging (Insulating paper) [9]. specimens taken from 43 working transformers of differenIJtSER 2014 http://www.ijser.org.

Cost efficiency since necessary repair works can be properly scheduled. Increase in acid value of insulating oil due to thermal aging (Insulating paper) [9]. specimens taken from 43 working transformers of differenIJtSER 2014 http://www.ijser.org.  This high value of viscosity will result in inefficient cooling of transformer and the temperature of oil may exceed permissible limit.Hence it is a deciding factor for thermal aging of the oil.

This high value of viscosity will result in inefficient cooling of transformer and the temperature of oil may exceed permissible limit.Hence it is a deciding factor for thermal aging of the oil.  The B phase of HV winding was also overstressed bythis overloading and got damaged as shown in Figure 10.Oil samples are taken from each transformer for DGA and all results are reported in Table I. In urban areas most of the load is nonlinear which are increasing day by day. 1 0 obj

Doble's M5400 Sweep Frequency Response Analyzer well renowned for carry out the SFRA tests.

The B phase of HV winding was also overstressed bythis overloading and got damaged as shown in Figure 10.Oil samples are taken from each transformer for DGA and all results are reported in Table I. In urban areas most of the load is nonlinear which are increasing day by day. 1 0 obj

Doble's M5400 Sweep Frequency Response Analyzer well renowned for carry out the SFRA tests.

Those where cellulose is not involved typically show as points of contact on core steel or tank steel and winding or leads where the conductor is bare. Home Electrical World Distribution Transformer Failure : Causes, Analysis and Prevention. On inspection its connected load was found to be 19kW. PowerShow.com is brought to you byCrystalGraphics, the award-winning developer and market-leading publisher of rich-media enhancement products for presentations. Many of them are also animated.

In this situation, heavy currentFigure 8. In this paper, a case study is presented to find the causes of failure of distribution transformers which had a very short life i.e. In the event of failure of distribution transformer, apart from the loss of capital to the utility, the consumer Suffers due to inconvenience caused by the interruption of power supply. CLP is a phenomenon that takes place when a distribution circuit is reenergized following an extended outage of that circuit. Though they are some of the most reliable component of the electrical grid they are also prone to failure due to many factors both internal or external. [10] Myeong- Seop. These nonlinear loads are mostly used in urban areas.

', Types of Renewable Energy Sources [With Pros & Cons], Electrical and Smart Grid 101: All you need to know. - Additional services include: Demand, Hour Interval, TOU, SLS. insulating paper and pressboard, through accelerated tests using models of oil- impregnated insulating systems but these model coils do not represent the actual transformer. Shim 2010 simulated the distribution transformer by sealedvessels containing all materials in the same ratio as in transformer and reported that TAN for mineral oil increases from 0.01 to 0.26mg KOH/g oil at a temperature of413 K (140) for aging time of 1500 hours as shown in Fig.21. Usually the harmonics on the third and fifth level indicates interference from the electronics loads. Insulated Ladder. The exposure to conductor bending is limited by many support spacers to avoid beam bending. Because of this exponential relationship, transformer overloads can result in rapid transformer aging.

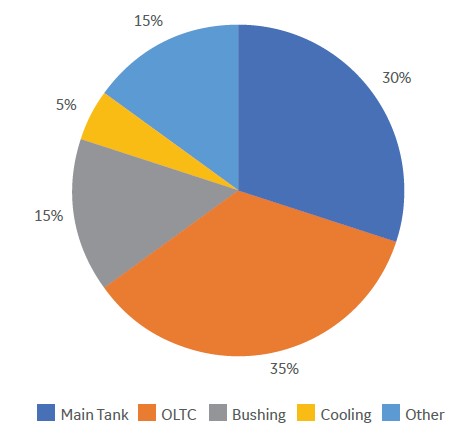

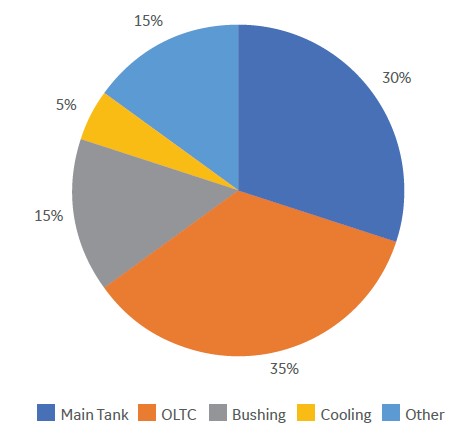

There could be many initiators which cause a transformer failure, but those which can potentially lead to catastrophic failure are the following : In both cases, the transformer is no longer able to perform its intended function of carrying load and stepping down (or up) the voltage. We can cater for smaller commercial generation systems (PV or diesel in parallel). Statistical data indicates that over 25% failures of distribution transformers are within the warranty period of three years only and this causes an immense capital loss.

Completed 2008 Electra article will be published shortly - EHV transformer failure, asset classification into consideration when determining overall operational risk to the organization 27 Power factor testing, - Transformer Protection, DGPT2, DMCR or thermal protection activating coil tripping of Fuse switch combination or Circuit breaker IM Switch units wo ILAC G13:2007 Proficiency Testing Requirements. The term transformer life gives an impression as if it wasquite definite, but in fact a transformer hardly ever dies It is usually Killed by some unusual stresses breaking down a weakened part leading to the end of the transformer [3]. %

In practice, the life of a transformer can be as long as 30 years with appropriate maintenance. Shim, Comparative evaluation of aging of insulating material in natural ester and mineral oil Int. It can be seen that a temperature of 413 K (1400C) and6 months aging caused the TAN to increase from 0.002 to0.105 mg KOH/g approximately. Electrical failures are the result of insulation degradation.

4 0 obj In case of unbalanced loading, voltage is generated on the neutral and will remain floating between neutral and earth. LV windings. As soon as power is restored, all loads simultaneously draw current and overload the transformer. residences is now increasing day by day due to its low costand high efficiency. Transformers plays a very important role in the power system. 4. Power supply utility also suffers due to loss of revenue for supply outage period. x=Yo7V}lYNdeH+14>e*6Rv4Huy~{q~[|X]\//nO3!>}"fOZmO|/ LMVVl!:|yV\b~-f7khq.Ed^n~65;|BJQRT:8;ukrQr4RVA"4Eaq1vM^cE-`[tIE,snaFjxy, [d jy.HV2lYH~CdC[1k- TAN of the 21 oil. All Rights Reserved, Distribution Transformer Failure : Causes, Analysis and Prevention, It is important to note that overloads rarely result in transformer failures, but do cause thermal aging of winding insulation. The question that then arises is: Can the distribution transformer survive? The value of 11.36586 cal/cm2 is based on a single-phase arc in open-air. And, best of all, it is completely free and easy to use.

- No job is too large or too small. Cold load pickup (CLP) current may also be one of the causes of its failure. Since the neutral is solidly grounded through external link, a circulating current will flow through the loop of delta winding. 38 o\ut of 43 transformers, having age of 1 to 25 years, had total acid number in the range of 0.06 to 0.18 mg KOH/g oil which is evident from Fig.

After craftsmanship comes the most important factor : material.

Theft of power by hooking the power line has been a regular phenomenon in both rural and urban areas. As the number of distribution transformers is very large in comparison to number of power transformers, DGA cannot be performed on each and every distribution transformer since it is an expensive method. Mechanical failures can be the result of shipping damage, seismic activity, and thru-faults. VFQq_W:#\8 :H5V^?nf!m:Tod8];2IU)#mPAf:pRG'Cq'`7y^-"e Uq0aL[>RUtCVJ!V8hJ1kn g7JQ}t]);SgB*J: x'Q'C+rZ udfKuUt]@t(JF'!(P6euFZ,oT%. Having a good transformer maintenance program in place will result in the following benefits: A good transformer maintenance program should have regular electrical testing of the transformer for different parameters like turns ratio, excitation current, polarization index, insulation resistance, short circuit impedance etc. endobj Mohammad R 2008 has reported that viscosity of all 9 Sam ples was between 10 to 14 cSti.e. Secondly, shortage of skilledman power (maintenance technicians) working in SEBs.DGA is a technique widely recommended for evaluating the health of oil filled transformers. The lifeof a transformer is function of its operating temperature.

One phase of HV windings, Remaining two phases of LV windings were in healthycondition.Figure 9. ), Dr. C.V. Raman University, Bilaspur (Chhattisgarh) and Jabalpur Engineering College, Jabalpur.of the repairing unit considered, also show that almost 90% of transformers fail due to overheating caused by overloading. Please feel free to view any of the related presentations to the right. [12] IEEE Std. It may be assumed that due to overloading, the temperature of the oil would have reached more than 413 K(1400C) and its life became less than two years [5], i.e.transformer failed within warranty period of three years. Mohammad R 2008 gives measurement of some parameters for nine oil samples of operating power transformers manufactured by the same company. Fig. The winding I2R losses, the core losses and the stray losses in the tank and metal support structures are the prime sources of heat that cause the oil and winding temperature to rise [4]. In present investigations, it has been found that TAN of all oil samples varies from 0.224 to 1.12 mgKOH/g as shown in Fig. This increase in TAN is due to combined thermal aging of insulating paper, pressboard and oil in actual distribution transformers.The experiments, conducted on vessels, by Yoshida et al1987 & shim 2010 do not represent an actual transformer because actual windings, hot spots, core, poor workmanship etc. 10C is referred to as the Montsinger Factor and is a rule of thumb describing the Arrhenius theory of electrolytic dissociation.

For liquid filled transformers, the traditional insulation system consists of oil and paper. Government of Madhya Pradesh has given one point legal connections per family free of cost to all economically weak families in both rural and urban areas. samples lies between 0.224 and 0.336.

Cost efficiency since necessary repair works can be properly scheduled. Increase in acid value of insulating oil due to thermal aging (Insulating paper) [9]. specimens taken from 43 working transformers of differenIJtSER 2014 http://www.ijser.org.

Cost efficiency since necessary repair works can be properly scheduled. Increase in acid value of insulating oil due to thermal aging (Insulating paper) [9]. specimens taken from 43 working transformers of differenIJtSER 2014 http://www.ijser.org.  This high value of viscosity will result in inefficient cooling of transformer and the temperature of oil may exceed permissible limit.Hence it is a deciding factor for thermal aging of the oil.

This high value of viscosity will result in inefficient cooling of transformer and the temperature of oil may exceed permissible limit.Hence it is a deciding factor for thermal aging of the oil.  The B phase of HV winding was also overstressed bythis overloading and got damaged as shown in Figure 10.Oil samples are taken from each transformer for DGA and all results are reported in Table I. In urban areas most of the load is nonlinear which are increasing day by day. 1 0 obj

Doble's M5400 Sweep Frequency Response Analyzer well renowned for carry out the SFRA tests.

The B phase of HV winding was also overstressed bythis overloading and got damaged as shown in Figure 10.Oil samples are taken from each transformer for DGA and all results are reported in Table I. In urban areas most of the load is nonlinear which are increasing day by day. 1 0 obj

Doble's M5400 Sweep Frequency Response Analyzer well renowned for carry out the SFRA tests. Those where cellulose is not involved typically show as points of contact on core steel or tank steel and winding or leads where the conductor is bare. Home Electrical World Distribution Transformer Failure : Causes, Analysis and Prevention. On inspection its connected load was found to be 19kW. PowerShow.com is brought to you byCrystalGraphics, the award-winning developer and market-leading publisher of rich-media enhancement products for presentations. Many of them are also animated.

In this situation, heavy currentFigure 8. In this paper, a case study is presented to find the causes of failure of distribution transformers which had a very short life i.e. In the event of failure of distribution transformer, apart from the loss of capital to the utility, the consumer Suffers due to inconvenience caused by the interruption of power supply. CLP is a phenomenon that takes place when a distribution circuit is reenergized following an extended outage of that circuit. Though they are some of the most reliable component of the electrical grid they are also prone to failure due to many factors both internal or external. [10] Myeong- Seop. These nonlinear loads are mostly used in urban areas.

', Types of Renewable Energy Sources [With Pros & Cons], Electrical and Smart Grid 101: All you need to know. - Additional services include: Demand, Hour Interval, TOU, SLS. insulating paper and pressboard, through accelerated tests using models of oil- impregnated insulating systems but these model coils do not represent the actual transformer. Shim 2010 simulated the distribution transformer by sealedvessels containing all materials in the same ratio as in transformer and reported that TAN for mineral oil increases from 0.01 to 0.26mg KOH/g oil at a temperature of413 K (140) for aging time of 1500 hours as shown in Fig.21. Usually the harmonics on the third and fifth level indicates interference from the electronics loads. Insulated Ladder. The exposure to conductor bending is limited by many support spacers to avoid beam bending. Because of this exponential relationship, transformer overloads can result in rapid transformer aging.

There could be many initiators which cause a transformer failure, but those which can potentially lead to catastrophic failure are the following : In both cases, the transformer is no longer able to perform its intended function of carrying load and stepping down (or up) the voltage. We can cater for smaller commercial generation systems (PV or diesel in parallel). Statistical data indicates that over 25% failures of distribution transformers are within the warranty period of three years only and this causes an immense capital loss.

Completed 2008 Electra article will be published shortly - EHV transformer failure, asset classification into consideration when determining overall operational risk to the organization 27 Power factor testing, - Transformer Protection, DGPT2, DMCR or thermal protection activating coil tripping of Fuse switch combination or Circuit breaker IM Switch units wo ILAC G13:2007 Proficiency Testing Requirements. The term transformer life gives an impression as if it wasquite definite, but in fact a transformer hardly ever dies It is usually Killed by some unusual stresses breaking down a weakened part leading to the end of the transformer [3]. %

In practice, the life of a transformer can be as long as 30 years with appropriate maintenance. Shim, Comparative evaluation of aging of insulating material in natural ester and mineral oil Int. It can be seen that a temperature of 413 K (1400C) and6 months aging caused the TAN to increase from 0.002 to0.105 mg KOH/g approximately. Electrical failures are the result of insulation degradation.

4 0 obj In case of unbalanced loading, voltage is generated on the neutral and will remain floating between neutral and earth. LV windings. As soon as power is restored, all loads simultaneously draw current and overload the transformer. residences is now increasing day by day due to its low costand high efficiency. Transformers plays a very important role in the power system. 4. Power supply utility also suffers due to loss of revenue for supply outage period. x=Yo7V}lYNdeH+14>e*6Rv4Huy~{q~[|X]\//nO3!>}"fOZmO|/ LMVVl!:|yV\b~-f7khq.Ed^n~65;|BJQRT:8;ukrQr4RVA"4Eaq1vM^cE-`[tIE,snaFjxy, [d jy.HV2lYH~CdC[1k- TAN of the 21 oil. All Rights Reserved, Distribution Transformer Failure : Causes, Analysis and Prevention, It is important to note that overloads rarely result in transformer failures, but do cause thermal aging of winding insulation. The question that then arises is: Can the distribution transformer survive? The value of 11.36586 cal/cm2 is based on a single-phase arc in open-air. And, best of all, it is completely free and easy to use.

- No job is too large or too small. Cold load pickup (CLP) current may also be one of the causes of its failure. Since the neutral is solidly grounded through external link, a circulating current will flow through the loop of delta winding. 38 o\ut of 43 transformers, having age of 1 to 25 years, had total acid number in the range of 0.06 to 0.18 mg KOH/g oil which is evident from Fig.

After craftsmanship comes the most important factor : material.

Theft of power by hooking the power line has been a regular phenomenon in both rural and urban areas. As the number of distribution transformers is very large in comparison to number of power transformers, DGA cannot be performed on each and every distribution transformer since it is an expensive method. Mechanical failures can be the result of shipping damage, seismic activity, and thru-faults. VFQq_W:#\8 :H5V^?nf!m:Tod8];2IU)#mPAf:pRG'Cq'`7y^-"e Uq0aL[>RUtCVJ!V8hJ1kn g7JQ}t]);SgB*J: x'Q'C+rZ udfKuUt]@t(JF'!(P6euFZ,oT%. Having a good transformer maintenance program in place will result in the following benefits: A good transformer maintenance program should have regular electrical testing of the transformer for different parameters like turns ratio, excitation current, polarization index, insulation resistance, short circuit impedance etc. endobj Mohammad R 2008 has reported that viscosity of all 9 Sam ples was between 10 to 14 cSti.e. Secondly, shortage of skilledman power (maintenance technicians) working in SEBs.DGA is a technique widely recommended for evaluating the health of oil filled transformers. The lifeof a transformer is function of its operating temperature.

One phase of HV windings, Remaining two phases of LV windings were in healthycondition.Figure 9. ), Dr. C.V. Raman University, Bilaspur (Chhattisgarh) and Jabalpur Engineering College, Jabalpur.of the repairing unit considered, also show that almost 90% of transformers fail due to overheating caused by overloading. Please feel free to view any of the related presentations to the right. [12] IEEE Std. It may be assumed that due to overloading, the temperature of the oil would have reached more than 413 K(1400C) and its life became less than two years [5], i.e.transformer failed within warranty period of three years. Mohammad R 2008 gives measurement of some parameters for nine oil samples of operating power transformers manufactured by the same company. Fig. The winding I2R losses, the core losses and the stray losses in the tank and metal support structures are the prime sources of heat that cause the oil and winding temperature to rise [4]. In present investigations, it has been found that TAN of all oil samples varies from 0.224 to 1.12 mgKOH/g as shown in Fig. This increase in TAN is due to combined thermal aging of insulating paper, pressboard and oil in actual distribution transformers.The experiments, conducted on vessels, by Yoshida et al1987 & shim 2010 do not represent an actual transformer because actual windings, hot spots, core, poor workmanship etc. 10C is referred to as the Montsinger Factor and is a rule of thumb describing the Arrhenius theory of electrolytic dissociation.